Delivering superior frying and filtering systems and cutting edge food-processing technologies and support on a global scale

JBT Stein & alco has been industry leaders in automated food processing and commercial frying solutions for more than 60 years. Our decades of experience, tenacity, genuine passion for what we do, and knowledge and understanding of our customers’ needs have been driving forces in helping us grow and thrive in domestic and international markets.

Our innovative frying and filtering equipment and our other commercial-grade products are favored by restaurants, coffee shops, cafes, bakeries, and other retailers worldwide. In addition to our incredible, hard-working teams of engineers and R&D specialists, our administrative staff make it their mission to deliver unparalleled customer service to our partners around the globe.

Read on to learn more about how we can help you deliver high-quality, delicious fried foods to your customers, wherever they may be.

Over 60 Years of Experience

Our commitment to innovating food-processing technology has been in the works for over half a century, beginning when Sam Stein sought to curate and expand the automated batter and breading market in the 1950s. Ever since we debuted our very first frying-based product, the Stein Fry-O-Matic – which began development in 1966 – we have remained dedicated to perfecting fryer solutions.

Our cutting-edge solutions in the industry have revolutionized frying technology, and we constantly strive to push the boundaries of frying machinery and capabilities. With our extensive and growing collection of frying, filtering, and conveying systems, Stein has helped introduce a whole new world of possibilities.

Features & Benefits

Feeding large numbers of people is a complex and demanding task. We’re committed to understanding and addressing the specific, ever-evolving needs of all of our customers.

We develop solutions to address old and new obstacles, improve operational and product outcomes, ensure safety and compliance in a range of markets around the world, and ensure that we never stop innovating. Your goals, challenges, and needs guide each and every development decision we make to ensure we consistently deliver the most cutting-edge technologies and proven strategies for success.

- Diverse range of equipment – Direct-fired, thermal-fluid, and gas-heat frying systems; force-flow and centrifugal-style hot oil filters

- Product and process flexibility – Equipment, resources, support, and training designed to meet a diverse range of global and domestic needs, regulations, and capacity requirements

- Superior food quality – Proprietary THERMoFIN technology delivers gentle heat transfer to prevent oil from degrading

- Unmatched cost-effectiveness – Equipment and support designed to decrease long-term oil costs, limit training requirements, and adapt to changing market and capacity needs enables long-term profitability

- Maximum output – Cutting-edge upgrades to the proven THERMoFIN® frying technology deliver maximum product output and operating economy

- Market-driven innovation and expertise – Continuous research and development to ensure the infusion of the most up-to-date food-processing technology in every fryer and filter

- Increased food and user safety – User-friendly controls, improved cleanability, and built-in automatic safety features

- Equipment financing – Traditional loans or lease-purchase structures with terms of 36 to 84 months, and seasonal rentals to match your cash flow

- Ongoing support – expert technical service and advice, equipment maintenance and repair, and productivity recommendations at your fingertips

To learn more about these features and how they can benefit you and help you reach your objectives, contact our team.

Comprehensive Solutions & Support for Diverse Markets

Trusted leaders in the commercial-frying solutions industry, Stein & alco are your go-to source for improving your long-term business outcomes. Our product offerings and aggregated experience and expertise are unmatched. We provide bold, proven solutions for diverse and changing customer needs around the world. Your requirements and challenges are unique, and our solutions are specific and targeted to your industry and markets.

Our Customer Care team is made up of the world’s leading industry experts, dedicated to providing answers to the most challenging questions you face and assisting you in maximizing your return on investment and serving your customers as effectively as possible. We also offer competitive rates and favorable terms when you finance your equipment through JBTEF.

Trusted Brands

In our long history, our primary goal has always been to provide the most efficient, cost effective, and reliable frying solutions to our partners and customers. Our passion for innovation has led to some of the most notable technological achievements in the frying industry and we continue to expand our designs, expertise, and partnerships to this day.

We have remained dedicated to understanding what it is our customers value in frying machinery by providing practical and cost-effective solutions. This is how Stein & alco has maintained its superior reputation as trusted brands for so many years.

Innovating & Perfecting Frying Solutions

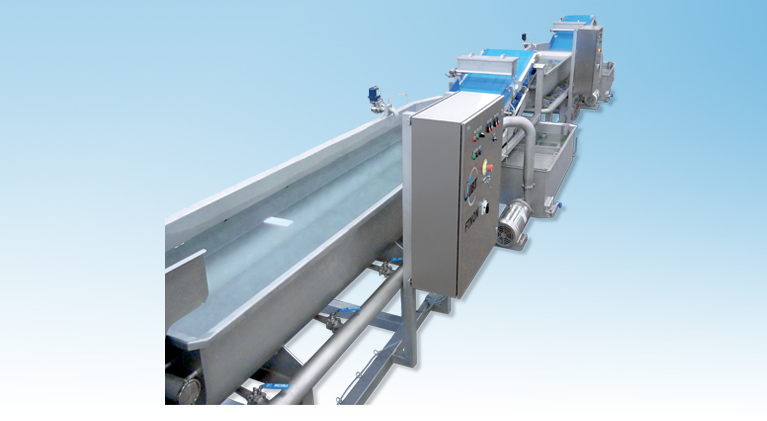

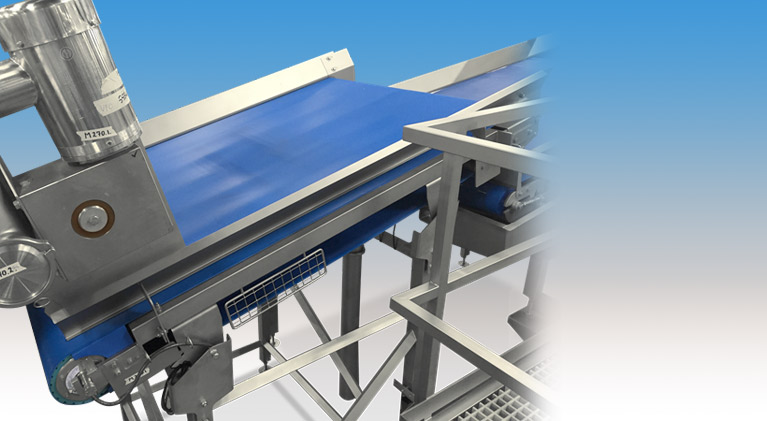

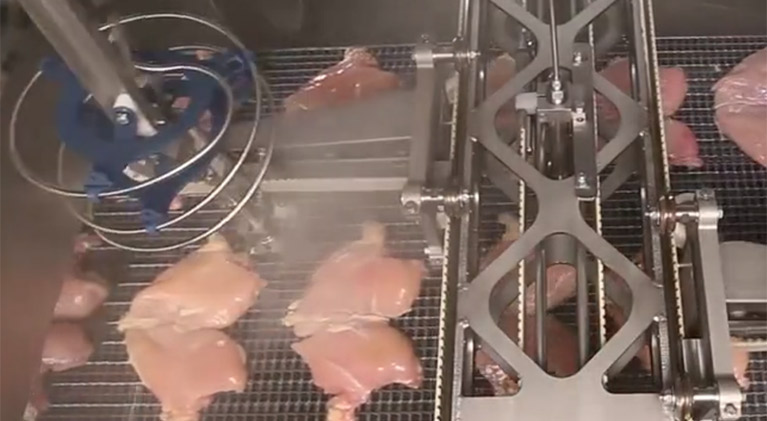

Our products are designed to optimize taste and food integrity while also increasing productivity and simplifying the frying process. Automation has always been at the core of our business operations. With conveyorized frying and advanced heat-transfer technology, our products have broadened the scope of what is possible in modern frying, while also staying true to our passion for consumer safety, market flexibility, user-focused management, and product quality.

Our mission has been to create groundbreaking technologies that not only perfect food quality and presentation but also exemplify machine reliability and user safety.

Related Products

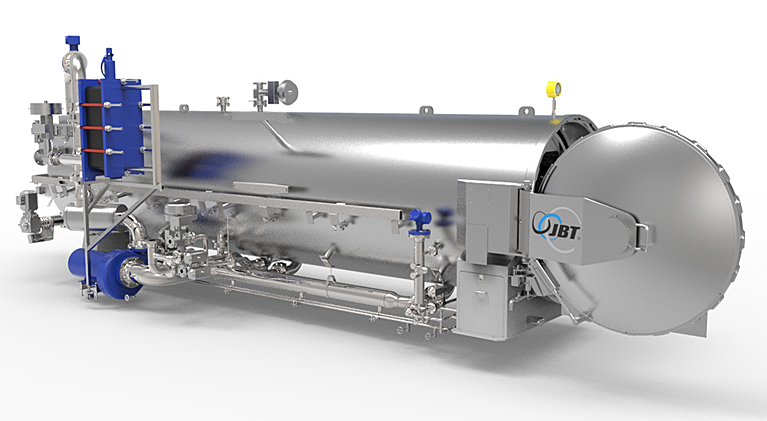

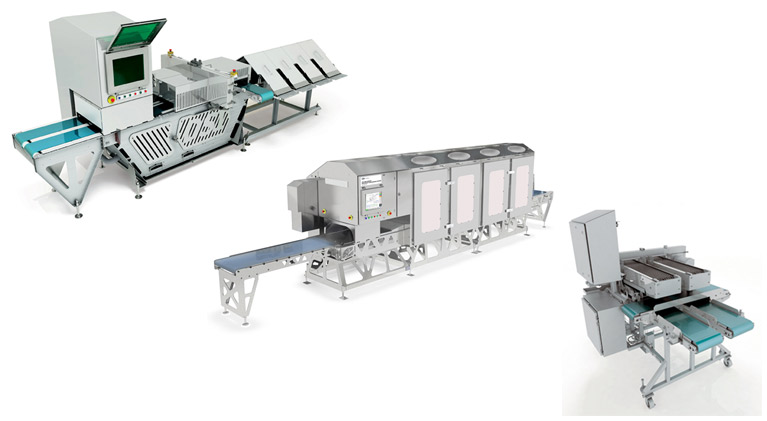

If you’re in the business of providing delicious fried foods, then you know just how important it is to have top-quality, dependable machinery at your disposal. From our TFF THERMoFIN® Conveyorized Thermal Fluid Immersion Fryer, which perfects gentle heat transfer and has become the top industry choice fryer for convenience foods, to the MX-MicroMax® Series Centrifugal Hot Oil Filter, which maximizes oil quality and extends the life of oil usability, our collection of sophisticated and state-of-the-art frying products are sure to provide you with the functionality and capabilities you’re looking for.

Our goal is to provide you with the best in frying technology and consumer service. Under the JBT umbrella, Stein & alco are armed with the knowledge, connections, and determination to help you make your dreams a reality!

An Innovative & Integrated Approach to FoodTech

At JBT, our goal is to provide food-processing solutions for all levels and industries. We specialize in providing systems and knowledge that target the specific needs of your market, while also offering a wide range of equipment that is reliable, customizable, and effective.

We’re here to offer you the very best in food-processing technology and equipment to ensure that you reach your goals no matter the specific needs and challenges of your industry.

Revolutionary Technology You Can Trust

JBT’s collection of equipment and machinery is always expanding. We promise to listen to your needs and provide you with extensive options to suit your specific business goals. We have always prioritized customizability, user safety, and product quality and we ensure our products have the highest standard of machine capabilities and usability. By working with JBT you’ll be able to:

- Browse a substantial catalog of premium equipment

- Customize production designs and operations

- Utilize equipment from a variety different brands to optimize production and meet your goals

- Replace individual parts and pieces of equipment to keep your product line running smoothly

We also offer personalized services such as upgrade kits, parts, service and maintenance, and training.

Diverse Markets, Complete Solutions

JBT works with companies across many markets and all around the globe. We benefit from the diversity of our partners and their various industries. Innovation and defying the status quo is what we do best. We strive to provide the most modern and innovative commercial-grade equipment to help you deliver the highest-quality food products to your customers. The markets we specialize in include:

- Bread & Pasta

- Coffee & Tea

- Fish & Seafood

- Fruits & Nuts

- Non-Foods

- Pet Foods

- Pharmaceuticals

- Poultry & Meat

- Ready Meals

- Vegetables & Potatoes

Your Leader in FoodTech Solutions

Stein has earned a reputation for excellence and cutting-edge innovation in frying and food-processing technology, and that’s just the beginning. Across industries and international borders, JBT provides the most advanced and comprehensive food-processing equipment, technology, support, expertise, and resources that exist in the world today. We can help you achieve your goals and reach greatness in your markets, now and in the future.

Building Long-Term Relationships With Our Partners

At JBT, you’re more than just another sale. We’re focused on the future, and we believe the future is better if we work together. We see the importance of collaboration because we know that helping you reach your goals is the best way for us to reach ours. We want to understand the challenges you face in serving your customers and achieving success, so we can help you get there.

Over the years, we’ve earned a reputation as a conscientious and people-oriented company, and we work every day to ensure we stay that way. We’re committed to providing the highest possible value for our partners, and that means building and maintaining long-term relationships. This allows us to understand you better over time and serve you more effectively in the future.

Our Innovative Centers for Research & Development

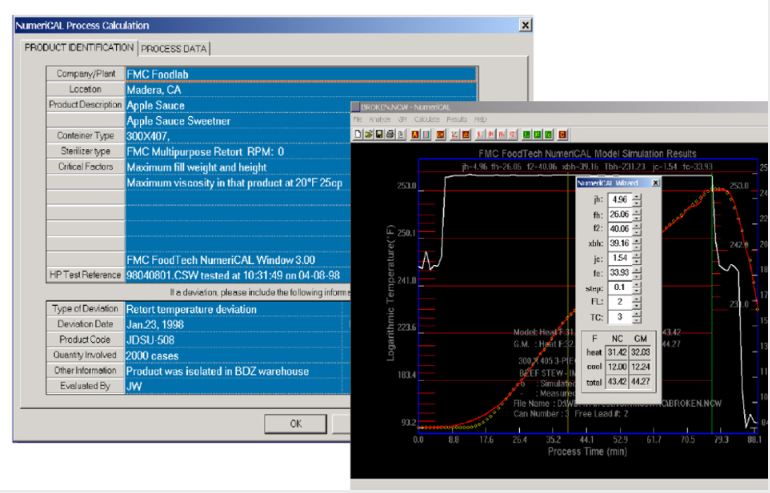

JBT grants our partners access to our global Research & Technology Centers. These centers act as worldwide hubs of innovation in the food-processing industry, and they’re designed to aid you in perfecting your processes, developing your goals, and achieving excellence.

Our R&T centers provide unique and coveted access to the world’s most advanced technologies, data, and expertise. Within their walls, you can test equipment, explore and try a variety of production-line setups, perfect your recipes, optimize your methodologies, and validate product safety.

Trusted Expertise & Support

As an industry leader in diverse domestic and global FoodTech markets for over a century, JBT is uniquely positioned to provide comprehensive guidance to address your toughest challenges. Our team of experienced and knowledgeable experts are here to act as your go-to resource and help you achieve your business goals and improve outcomes for both you and your customers.

We provide you with this comprehensive and high-level support because we know how difficult your challenges are. We’re dedicated to helping you improve your operations, enhance your processes, and gain a competitive advantage in your specific markets.

Contact us today with your most pressing questions or concerns. Our team of experts is here to help!