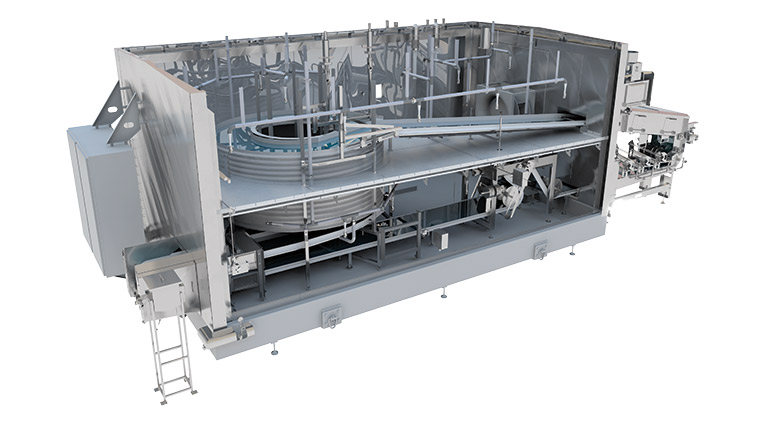

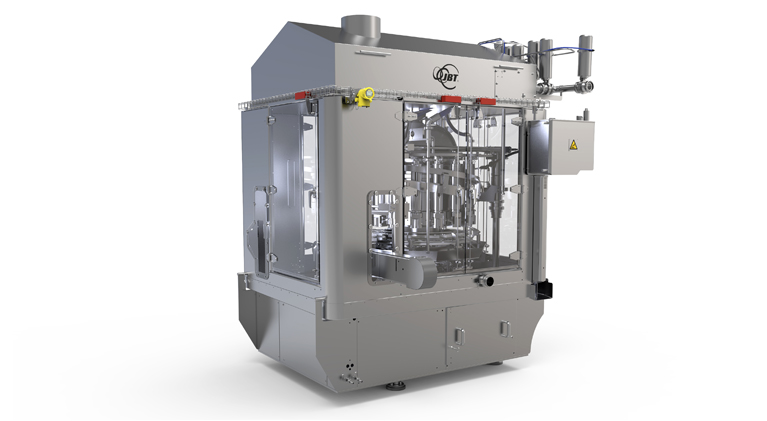

Broad range of technologies to fill and close pumpable or free-flowing products in rigid and semi-rigid containers

JBT, The Smart Option for Filling & Closing

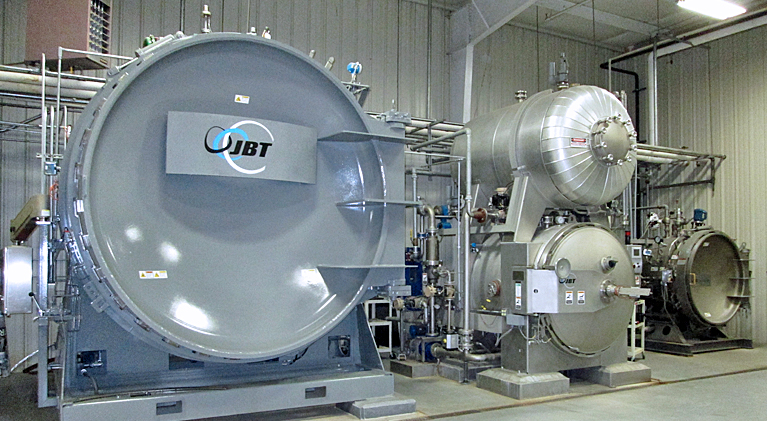

JBT fillers and closers are perfect for the feast of liquid and spreadable foods flowing through the modern marketplace. With the ability to work with so many foods and container types, JBT filling and closing technology is both popular and highly respected in the industry.

You, too, can profit from our well-designed, heavy-duty filling and closing equipment. You’ll come to love the easy cleanability, high operating efficiency, lower per-unit cost, and operator safety features. Plus – with the happiness of your customers in mind – JBT solutions provide the optimal mix of product quality and product safety.

Fillers & Closers for Every Product & Container

JBT’s vast collection of fillers and closers can handle whatever making your food item entails. You’ll find filling solutions for products like:

- Milk and liquid dairy products in bottles, jars, and cups

- ESL milk

- Yogurt

- Cheese

- Processed cheese

- Dairy

- Milk and liquid dairy products in cans

- Sweetened condensed milk

- Evaporated milk

- Pasteurized milk

- Chocolate and Flavored milk

- Kefir

- Labneh

- Yogurt (stirred, set, drinking & fruit)

- Nutraceuticals in cans and bottles

- Probiotic and cultured yogurt

- Infant formula powder in cans

- Baby food in jars or cans

- Juices with particles in bottles and cans

- Clear juice

- Juice with pulp

- Turbid juice

- Hot fill juices

- Jams and sweet spreads in jars

- Jams

- Marmalades

- Peanut butter

- Choco spread

- Honey

- Cooking sauces in jars and cans

- Pesto

- White sauces

- Red sauces

- Pasta sauces

- Tomato sauce and paste

- Harissa

- Spreadable meats and liver

- Condiment sauces in bottles and jars

- Mayonnaise

- Ketchup

- Soy sauce

- Vinegar

- Mustard

- Fish sauce

- Oyster sauce

- Tuna in cans

- Wine and spirits in bottles

- Whisky fillers

- Wine

- Vodka

- Rum

- Tequila

- Fruits, vegetables, and ready meals in cans

- Corn

- Peas

- Tomatoes

- Frozen vegetables

- Beans

- Edible oil in bottles

- Soy oil

- Olive oil

- Vegetable oil

- Nut oil

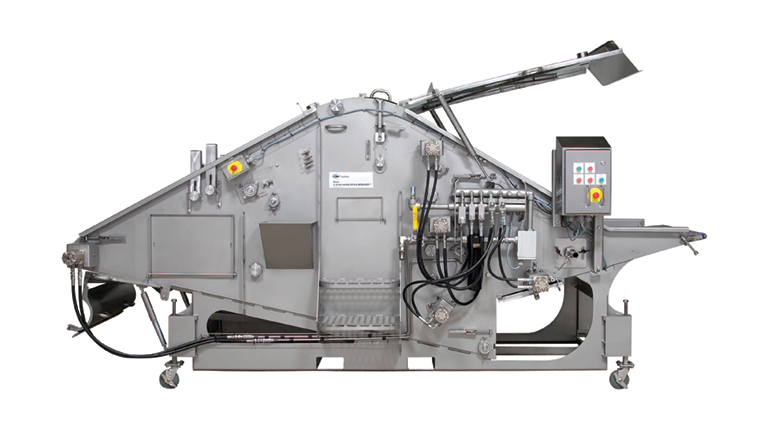

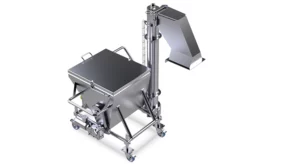

Our filling technologies — from granular filling machines to bottle filling machines — can deposit pumpable or free-flowing foods into a variety of rigid and semi-rigid containers:

- Plastic tubs or cups

- Glass, PET, or plastic jars

- PET, rPET, PR, PP, PS, glass, or HDPE bottles

- Food, beverage, powder, metal, or composite cans

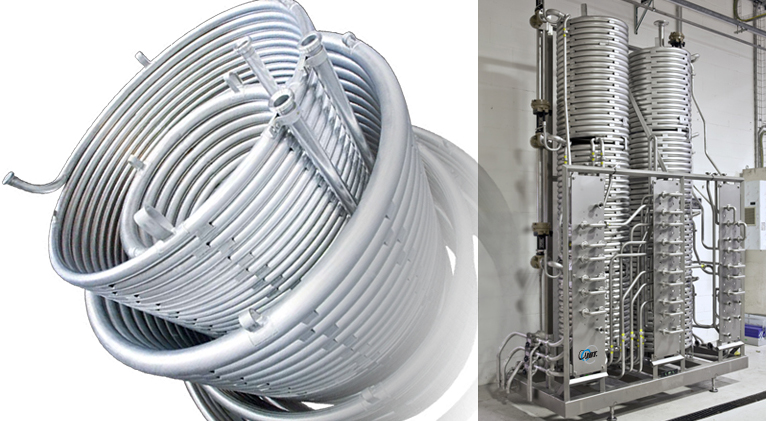

Our closing technologies span a broad range of applications for liquid, semi-rigid, and powder applications. We can process a variety of closure types:

- Double seam

- Foil, aluminum, or plastic

- Caps, TO, TOTO, PT, push-on, and screw

- ROPP closure

- IHS seal

Using our cutting-edge equipment locks in peak freshness and nutritional value, while ensuring the utmost food security.

Optimal Engineering Means Better Food Prep

Anything that optimizes your food processing activities is a boon to your business. JBT truly internalizes this concept. As such, it’s actually at the heart of our entire design process.

We’ve carefully and conscientiously engineered in features and functionality to maximize productivity, extend machinery lifespan, maintain equipment value, and more. You get all this while still ensuring your product meets the highest food safety and quality standards and package integrity. The outcome – a jackpot for you – includes:

- Construction using the latest processes and materials

- Compatibility with other food processing machinery

- Adaptable to your production needs

- Takes less time for training and to deploy

- Increased service longevity and higher resale value

Filling & Closing Made Easy

JBT has equipment for every task, and you can organize these machines into a full production line. Creating a bespoke, purpose-built solution for your food product could resolve many of the challenges you face. Here’s how:

- Automated processing

- Simple, intuitive controls

- Minimal operator training needed

- Reduced risk of human error

- Customizable and configurable to suit your specific needs

Better still, our filling and closing machinery makes achieving your operational targets – generating and maintaining product quality, boosting productivity, eliminating downtime, etc. – simple. It’s all part of the JBT experience.

Reliability: It’s Built In

There’s no room in your schedule for production delays. When processing equipment is offline, your ingredients can spoil, your workers are idle, and you could miss critical deadlines. You need machinery you can depend on – all day, every day.

At JBT, we thoroughly understand the downstream effects of production interruptions. That’s why our filling and closing equipment’s made to withstand the test of time (and use). It’s rugged, constructed from the sturdiest materials. Because of this attention to excellence, you’ll enjoy:

- Cheaper, easier, and less maintenance

- Fewer and less severe operational issues

- Fewer and shorter work stoppages due to operational issues

- Higher operator safety

- Industry low total cost of ownership

Features & Benefits

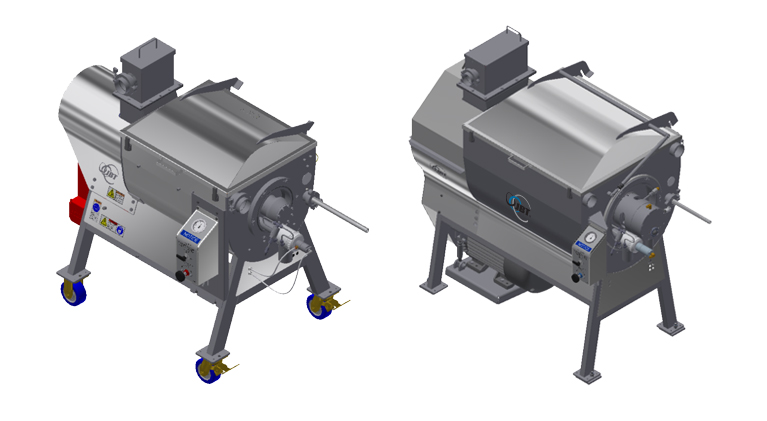

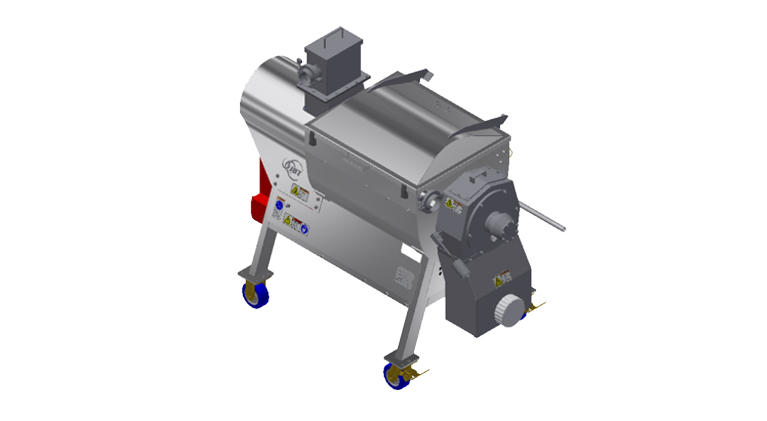

JBT’s filling and closing equipment is packed with features you’ll appreciate. All these capabilities make for food production that’s consistently as rapid, accurate, and safe as possible.

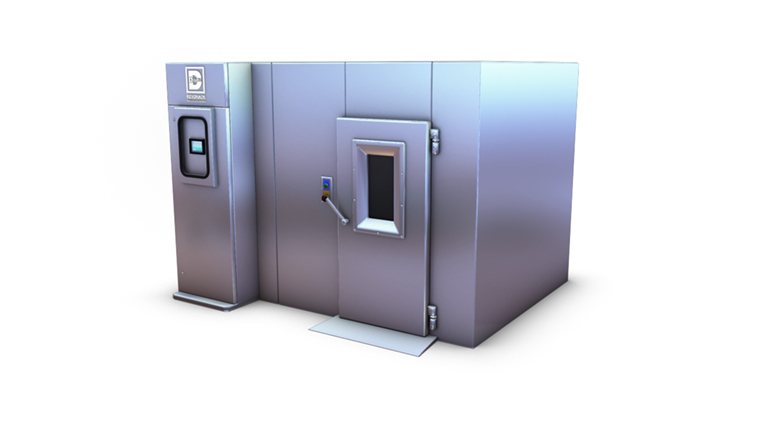

- Adaptability – Can integrate other machines for rinsing/decontamination, filling, and closing solutions

- Extensibility – Can add on secondary equipment for further processing

- Options – Several filling technologies – for weight filling, volumetric filling, level filling, vacuum filling, and particulate filling – and closing technologies – for food, beverages, and powder – available to accommodate a variety of food processing

- Efficient – Increase yields with less product loss

- Productive – High operating efficiency and minimum downtime

- Sanitary – Superior hygienic design for easier and better cleanability and higher food safety and quality

- Streamlined – Automatic CIP or WIP saves time and effort

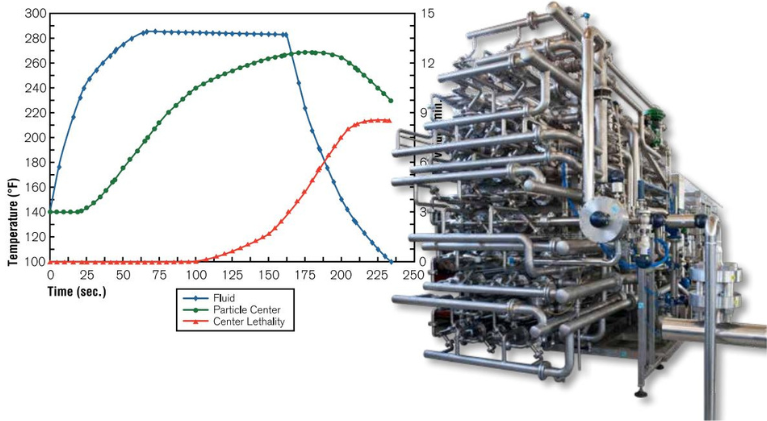

- Innovation – Extensive research and testing capabilities to optimize product development

- Support – Global service, support, and resources

If you have any questions about these features – or how they benefit your operations – contact our team today.

Explore Our Fillers and Closers

Only The Best Brands

Your business is important. Keeping it moving at its normal cadence is maybe more critical. It makes sense that you’d only want quality equipment – that you can trust – in your plant.

We’re right there with you. That’s why we only carry the top makes and models. Food businesses worldwide have been happily counting on the JBT and PLF International brands for years.

Why are they more pleased than that punch you’re bottling? They’re crafting their goods safely and efficiently. They’re realizing cost and productivity advantages that come with a production line outfitted with machinery by reputable brands.

All the FoodTech Solutions You Need

Because each kind of product has its own preparation, JBT offers a full complement of high-quality equipment. You’ll find solutions for:

Plus, JBT has upgrade kits, detergents and lubricants, and parts — as well as service, maintenance, and training – to keep your set-up humming.

Establishing Your End-To-End Food Production Line

JBT affords you the flexibility and options your business demands. You can pick and choose individual pieces of machinery or assemble a whole new processing system. Either way, our extensive portfolio of products has at least one or two options for each step of production.

With the quality, quantity, and variety of food processing equipment we offer, you’re able to:

- Conveniently one-stop shop for your equipment

- Tailor your production line to accommodate your requirements

- Mix and match brands to get exactly what you need

- Easily replace or upgrade components of your current production line

- More agilely respond to production changes

- Scale your production more seamlessly

Nobody can supply you with the proper equipment, to get the job done right, like JBT can. We make establishing your production line simple and much less stressful.

JBT, The Ideal FoodTech Partner

Your search could be over. With JBT, you’ve got the total package. All of your business’s food processing needs – beyond just filling and closing – are covered under our one roof.

People- & Needs-Focused

At JBT, it’s not good enough to just make a sale and move on. That’s an outdated paradigm that really doesn’t let us show you the attention and respect you deserve.

Instead, we strive to build a productive long-term relationship with you. It’s this collaborative approach that enables us to serve you more thoughtfully and holistically now – and down the line.

Innovation Centers

More than just a test kitchen or lab, JBT’s Research & Technology Centers are a unique and remarkable perk available to you. At these facilities, you can:

- Try out machines and production line configurations

- Hone your recipes and techniques

- Validate product quality and safety

- Access technical expertise and tons of data

Engage with JBT Experts

JBT’s been in the FoodTech industry since the 1880s. Take advantage of our substantial knowledge and experience! It’s a great way to get the most benefit from your JBT products and services.

Our dedicated and skilled team is eager to provide this next-level support. We know running a food processing enterprise can be complex and sometimes a bit of help makes all the difference.

We’re here if you have questions, aren’t sure which machines to buy, or need professional input as you plan for capital investment or production scaling. Feel free to contact us anytime.