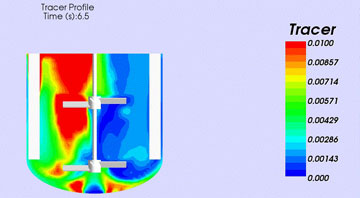

A&B Process Systems carries extensive experience in the design, fabrication and installation of batch process systems and blend mix tanks and kettles for dosing of liquids, slurries, gases and bulk solids via loss-in-weight and gain-in-weight designs. We utilize a variety of flowmeter and load cell technologies, and can customize a variety of blending systems from agitation to low and high-shear mixing. Tanks and custom agitators can be skidded for specific applications. Click the image to watch a time-lapse of a tank with a turbine agitator and static baffles. Illustrating the flow pattern of an ingredient (red) being added to a batch and the time it takes to incorporate to a uniform/homogeneous mixture.

Click the image to watch a time-lapse of a tank with a turbine agitator and static baffles. Illustrating the flow pattern of an ingredient (red) being added to a batch and the time it takes to incorporate to a uniform/homogeneous mixture.

Features & Benefits

- Small plant footprint

- Very versatile and flexible

- Available in several different options

- Easy to clean (optional Clean-In-Place system installation available)

- Each agitator type specializes in pre-determined applications, which makes it highly performant

Details

- Our batching and blending systems have several applications depending on the type of blenders used.

- All are designed and fabricated in conformance with 3-A, USDA, cGMP, ASME (U&R), BPE, FDA and API standards