Ensuring and extending the quality and shelf life of even the most sensitive food products

Why JBT for Aseptic Processing & Packaging

As a titan of the industry, you know that creating high-quality food products is a balancing act. Safety, stability, productivity, and cost get pitted against taste, nutrition, and product attractiveness. In the end, it all needs to come together.

JBT makes finding that equilibrium easy. The robustness and variety of our aseptic solutions are a worthy match to the rigor required for your products (even the most delicate ones!). Our years of helping to improve product quality and safety and the sheer number of our machines in the field prove this out.

In fact, more than 50% of all shelf-stable food products are filled, closed, or sterilized on JBT equipment. Among the many markets – including some of the most regulated – that leverage JBT aseptic systems are:

Below are a few more reasons why so many food producers turn to JBT for aseptic systems.

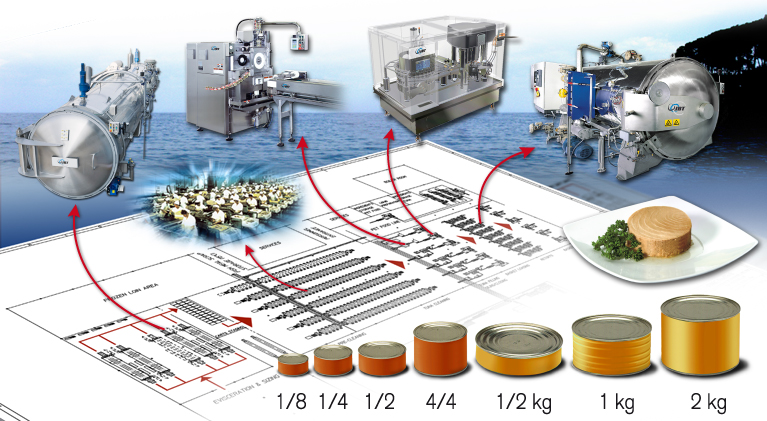

Aseptic Equipment for Every Product

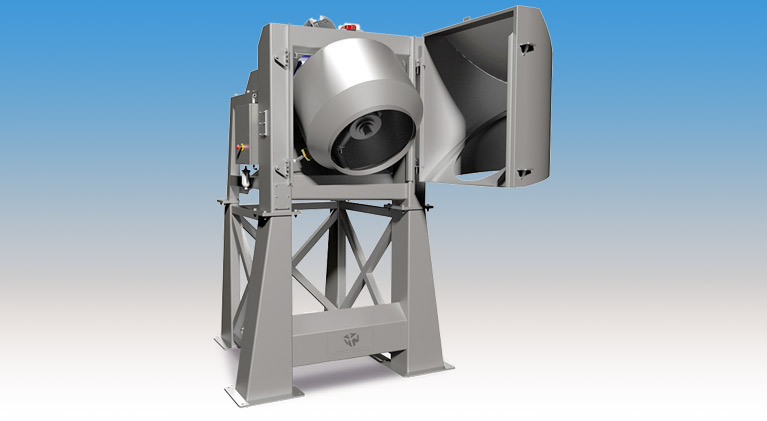

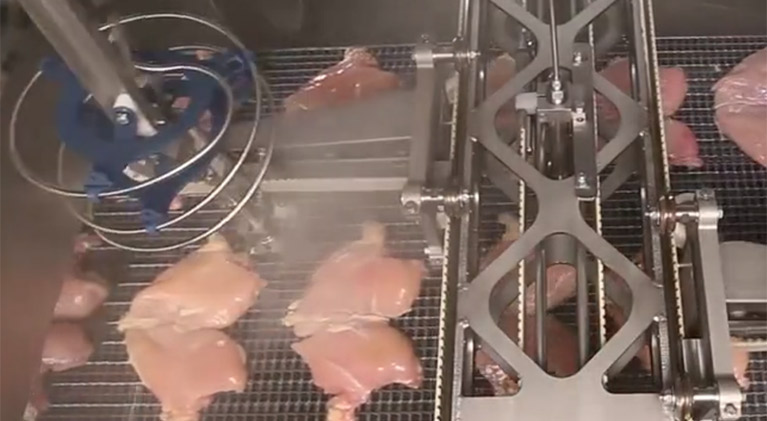

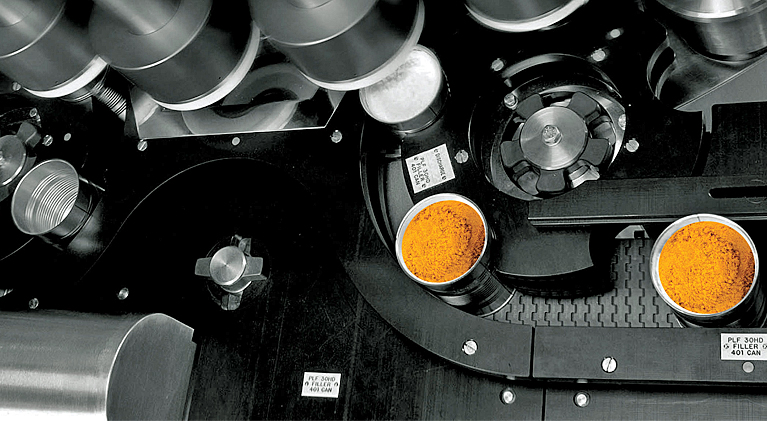

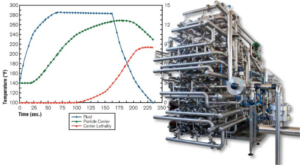

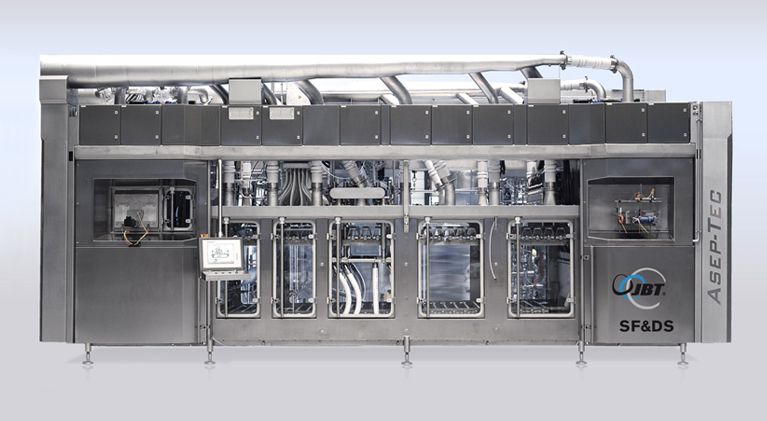

JBT’s impressive selection of aseptic fillers, pasteurizers, sterilizers, storage tanks, and bottle blow molding units are ready to process your food product. Using our state-of-the-art equipment seals in the freshness and nutrition consumers desires, while ensuring the food safety they need.

You’ll find aseptic processing solutions for products like:

Not only do our aseptic technologies process a wide a variety of foods, they work with many types of packaging:

- Plastic

- Steel or aluminum cans

- Jugs

Better Engineering for Better Results

Solutions that streamline your food production and bolster your business are an asset. JBT understands and agrees completely. It’s what drives our design and building efforts.

We’ve taken the time and care to engineer-in thoughtful functionality. You’ll appreciate features that bring about positive changes – like greater productivity, increased service life of your machines, advantageous cost per unit – to your operations. Here are some of the highlights of our smart designs:

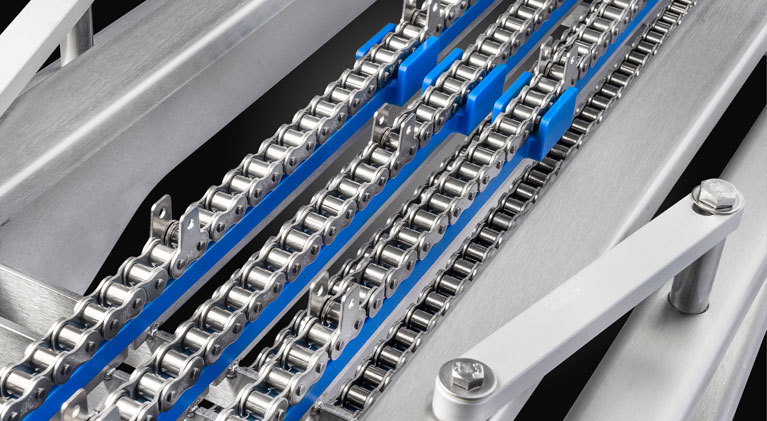

- Construction using the latest processes and best materials

- Compatibility with other food processing equipment

- Adaptable to meet your production requirements

- Quick production change-overs

- Easier to use

- Quicker roll out

- Greater machine longevity

- Higher resale value

Aseptic Processing, the Easy Way

JBT has a machine for every step of your production process. Even better, our pieces of equipment are able to integrate with each other. The beauty of this scenario is that you can create the exact processing line you need.

Maybe it goes without saying (we’ll say it anyway), but a personalized, purpose-built solution for your food product could prevent or resolve many common operational challenges. It does this by:

- Automating processes

- Simplifying controls and operation

- Minimizing operator training

- Reducing chances of human error

- Customizing and configuring your set-up to suit your unique needs

- Facilitating regulatory compliance

There’s more to the story than just stripping away bottlenecks and pain points from your food preparations. JBT’s aseptic processing machinery can help you reach functional targets – generating and maintaining product quality, eliminating downtime, and so on. Business and production successes go hand in hand with JBT technology.

Made to Last

Production stoppages are out of the question. You’ve got perishable ingredients ready to go, workers waiting to start, and customers expecting deliveries. As such, your factory floor only has room for long-lasting, heavy-duty equipment that’s going to work every time you power it up.

We fully comprehend the impact of unplanned downtime. It’s why our aseptic filling and other procession equipment is so solidly built. JBT uses only the sturdiest materials and manufacturing techniques. For you, this dedication to quality and detail means:

- Minimal, easier, and cheaper maintenance

- Fewer and less severe operational issues

- Fewer and shorter work interruptions due to operational issues

Features & Benefits

JBT’s aseptic systems are filled with all the features – and more! – that you want and need. These capabilities enable you to consistently produce food as quickly, precisely, and securely as possible.

- Productive – High-speed, bulk filling for over 100 processing hours

- Adaptability – Versatile solutions for total aseptic safety

- Customizable – Wide variety of sterilization configurations to meet product demands

- Options – UHT processing via indirect or direct heating

- Compliance – Comprehensive process control and production logs to meet regulatory requirements

- Assurance – Extensive research facilities to test your product/package combinations

- Support – Worldwide service, support, and resources

Contact our team if you have any questions about these features – or how they benefit your business.

Related Products

Brands You Know & Trust

Keeping your production line running at its regular pace is critical. It makes sense that you’d only want the best equipment – machinery you can count on – for your business.

JBT gets it – we’re manufacturers, too! That’s why we only offer the highest caliber makes and models.

Producers around the globe churn out goods on JBT branded equipment. They’re operating safely and efficiently, realizing cost and productivity advantages, and more. They’ve been doing so with great success for years – in large part due to their dependable JBT machinery.

Your Total FoodTech Solutions Provider

Every food product is different. Each has its own ingredients, preparation, and other requirements. To address this, JBT carries an expansive portfolio of best-in-class equipment.

You’ll find systems for:

To get the most out of your set-up, JBT also has upgrade kits, lubricants, and parts – as well as service, maintenance, and training.

Assembling Your Food Production Line, The Smart Way

Sometimes you just need a single piece of equipment. Other times you have to build out an entire processing line. Either way, JBT gives you the flexibility your business calls for.

With the quality, quantity, and variety of JBT food processing machines available, you can:

- Conveniently source your equipment from one supplier

- Customize your production line to suit your requirements

- Blend brands to get the exact mix of machinery you need

- Replace or upgrade components of your current production line without hassle

- React to production changes with agility

- Scale your production more smoothly

Whatever your food product is – JBT makes establishing your production line a simpler, more pleasant experience. You’ll get the right equipment to properly complete tasks. It’s an all-around win.

JBT, the FoodTech Partner You Crave

Being in the food business is no picnic – it’s rife with complexities and challenges. Luckily, with JBT, you’ve got a full-service ally. We can satisfy all your processing needs – beyond just aseptic solutions.

A You-Focused Approach

JBT rejects the outdated paradigm of making a sale and moving on. Instead, we’re big on forming and fostering long-term, collaborative connections with our customers. We want to get to know you and your business!

It’s really the only way we can get a chance to show you the attention and respect you deserve. Building this rapport lets us serve you more thoughtfully and holistically – today and for all the tomorrows to come.

Innovation Centers

JBT’s Research & Technology Centers are a unique and noteworthy benefit to you. More than just a test kitchen or lab, these facilities enable you to:

- Test machines and production line configurations

- Perfect your recipes and methodologies

- Validate product quality and safety

- Access to technical experts and data

Just imagine the troubles this could save you!

Connect with Experts

Did you know that JBT’s been in the FoodTech industry since the 1880s? That’s a long time and a lot of useful insights gained. Make use of our breadth of knowledge and experience!

JBT wants you to succeed in your endeavors. So, our talented and committed team is happy to provide you with premium-level support. We know it can help you get the most benefit from your JBT products and services.

We’re here if you have questions, aren’t sure which machines to buy, or need professional input as you plan for capital investment or production scaling. Feel free to reach out to us anytime.