JBT supplies both customized industrial products and services used in the food, beverage and non-food industries. We design, manufacture and service technologically sophisticated food processing systems for the preparation of meat, seafood and poultry products, ready-to-eat meals, shelf stable packaged foods, bakery products, juice and dairy products, and fruit and vegetable products. JBT systems can also be used in various non-food applications.

Ovens & Cookers

Precision cooking solutions to efficiently produce a broad array of high-quality animal- and plant-based food products at scale

In the food industry, it’s imperative that producers are in lockstep with always-changing consumer demands. To stay in sync, you need robust-yet-adaptive systems for cooking a veritable buffet of items. This needn’t be an issue for your business, though. JBT offers the most comprehensive portfolio of high-volume industrial cooking solutions available. This includes:

- HotCook

- Batch cookers

- Contact cookers

- Convection ovens

- Impingement ovens

- Spiral ovens

- Chargrillers and searing cookers

This full complement of ovens and cookers allows you to cook:

- Using baking, rotisserie, grilling, and other cooking methods

- Meat, fish, poultry, baked goods, vegetables

- Foods with or without bones

- Items that are breaded, battered, or marinated

- Without added or artificial oils or fats

As you can see, you have lots of truly useful options — which makes keeping pace with consumers that much simpler.

JBT Products Are Hot Stuff

You’ll find that JBT’s cookers and ovens are unbeatable when it comes to quality, competency, or technology. Go ahead and see for yourself.

Ovens

Experience unsurpassed cooking uniformity on a wide range of food products with our linear and spiral ovens, which have been revolutionizing food prep for decades.

Get details

Cookers

With the industry's widest selection of batch or continuous cooking systems, you’ll be able to process countless meat, fish, poultry, vegetable, and ready meal products.

Get details

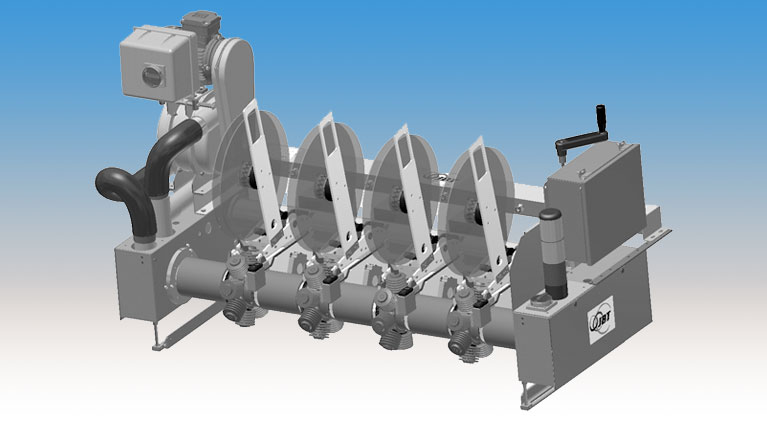

MultiPhase Cooking Components

Ensure that your production line has the right equipment in place to achieve its maximum potential with a set-up tailored to your manufacturing process.

Get detailsFeel free to contact us for additional details — we’d love to tell you more about this incredible equipment.

JBT, the Only Choice for Cooking Solutions

No production activity or environment is outside of JBT’s wheelhouse. Our unparalleled selection of equipment is up for the challenges of the day (or decade!).

Take our MultiPhase™ cooking approach — a star of our line-up — for instance. It delivers the right heat transfer mechanisms in the right sequence. This technique can be applied to individual pieces of equipment as well as selected combinations. It’s just one example of the flexibility and control you’ll enjoy by using JBT equipment.

Boosting Your Business with Better Engineering

JBT’s MultiPhase cooking is a game-changer.

But, honestly, it’s not an outlier among our offerings. In many ways, it’s very representative. Because we practice intentional engineering, JBT solutions are:

- Constructed with the best processes and materials

- Plentiful — at least one machine option for every production step

- Compatible with other processing machinery

- Customizable and configurable to your requirements

- Quicker and easier to deploy

- Require less training to operate

- Minimizing opportunities for human error

- More reliable machines

- Easier and cheaper to maintain

- Encounter fewer and less severe operational issues

- Have a longer service life

- Boast a higher resale value

Our equipment is designed to do more than just produce superior food products. JBT machines boost your business, too. As a result of having JBT machinery in-house, our customers regularly experience gains like:

- Increased efficiency

- Improved machine utilization

- Reduced equipment overhead costs

- Increased profit margins

- Better safety records

Our reputation for excellence and industry leadership role underscores this.

Features & Benefits

You need feature-rich combi cookers, forced air convection ovens, etc. We hear you — and have delivered. Check out some of the functionality we’ve baked into our machinery. They consistently make food production faster, safer, and more predictable.

- Speed — Fast cooking provides a higher yield

- Flexibility — Option of different cooking methods and mechanisms allows for a variety of products

- Hygienic — Highly cleanable machines for improved product quality and safety

- Switchover — Easy and quick changes between products for better productivity and more flexibility

- Heat — Independent electrical platen temperature control for better, more consistent thermal regulation

- Uptime — Intelligent design and robust construction result in reliable high performance

- Appearance — No belt marks on product mean favorable visual aesthetics are maintained

- Savings — Predictability, efficiency, and quality of systems slash lifetime ownership costs and operational costs

- Adaptability — Able to process a variety of products

- Innovation — Extensive testing capabilities to help facilitate product development

- Support — Global support staff to help as needed

Have questions about how these features can benefit your business? Just ask!

Trusted Brands — Stein, Double D, Formcook, & alco Models

You don’t need to be on a first-name basis with the premier industrial cooking machine manufacturers. JBT’s done all the due diligence and only offers the absolute best brands, like these:

Beyond the Compact Oven & Continuous Cookers

With our immense catalog of high-quality products and services, JBT’s well-positioned to help you tackle the many and diverse processing tasks on your punch list.

On top of things like dual cookers and convection ovens, you have your choice of systems for food preparation, sterilization, sealing, storage, transport, and more. Add on essentials — like detergents, lubricants, replacement parts, and upgrade kits — for a well-rounded solution.

You’ll soon come to appreciate the JBT advantage — a synergistic combo of flexibility, adaptability, expertise, variety, quality, and more that facilitates peak performance. Plus, with JBT, the process of setting up production couldn’t be more straightforward or stress-free.

Outfitting Your Entire Production Line

JBT’s ready to supply you with the solutions you need to create exemplary products. It doesn’t matter if you’re looking to replace one worn-out piece or furnish your new plant with a full assembly line.

Because we have the right machines to perform every step to perfection, you’ll be able to:

- Conveniently get equipment from one source

- Create a bespoke manufacturing line that fits your requirements

- Blend brands to get the exact machines you need

- Replace single components of your production line with less hassle

- Respond to changes with more agility

- More easily scale your business

With JBT, You’re Really Cooking Now

Look no further! JBT has all your foodtech needs covered.

A Better Approach

In our experience, “together” is better than “separate.” As such, we prioritize establishing a long-term, collaborative relationship with your business. This enables JBT to offer more holistic and thoughtful service. And it all but guarantees you’ll get even more value out of your engagement and equipment.

R&D Centers

Access to JBT’s Research & Technology Centers is a unique and momentous benefit of working with us. Much more than a test kitchen or culinary lab, these facilities let you test machines and production set-ups, refine your recipes and procedures, and tap into technical expertise and data.

JBT Experts at Your Service

For over a century, JBT’s dominated the FoodTech industry. You’re invited to make the most of the vast knowledge and experience we’ve amassed along the way. We provide his superior level of support because we want your business to flourish. Reach out to JBT anytime for help.

Ovens

We have long recognized that food processors strive for product differentiation, which means that no one specific cooking process can be the answer until all the product criteria are determined. The best cooking results are achieved only when the characteristics of the end product are objectively quantified. A thorough understanding of the end product allows processors to better define the raw materials, equipment, operating parameters and the proper sequence of the production process. This is where we can provide immense value. Armed with the broadest portfolio of industrial cooking equipment, we can provide the process versatility and know-how needed to fine tune virtually any industrial cooking process.

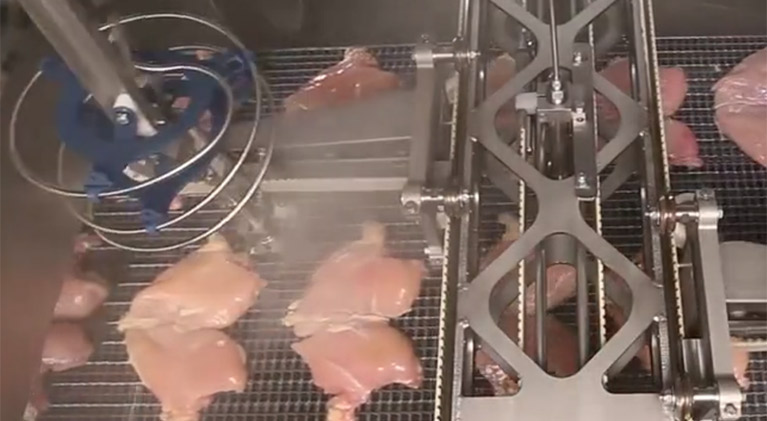

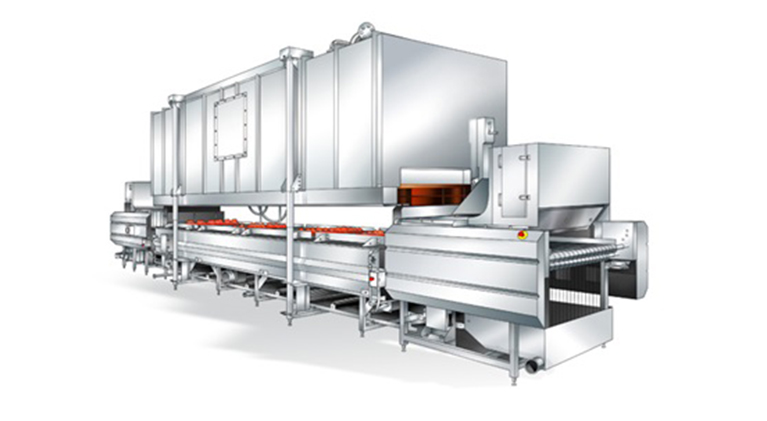

Double D Revoband Continuous Protein Oven

Our Double D Revoband Continuous Protein Oven combines continuous automatic high volume processing with accurate temperature and airflow control for high product yields. It has a unique combination of flexibility and control for excellent results on a wide range of products from bone-in poultry to steamed vegetables. The Revoband oven features precisely controlled vertical hot air directed at the product from above and below the belt. We designed the oven with adjustable fan speed control for each zone to provide unlimited flexibility.

Perfectly suitable for chicken fillets, wings & drumsticks, burgers, nuggets, fish sticks, back bacon, sausages, lasagna and other special applications

Features & Benefits

- High Velocity air provides consistent color development and uniform cooking results

- Precise control of temperature and production time for repeatable results

- Cook with steam and elevated temperature or steam only for process flexibility

- Indirect heat eliminates by-products of combustion for product zone

- Integrated CIP Clean-in-Place system for ease of cleaning

- Custom built to meet exact capacity, footprint, and application requirements

Details

- Designed for full cooking a wide range of coated and uncoated food substrates.

- Fully welded stainless steel enclosure

- Available in 600mm and 1000mm usable belt widths

- Available with electric drives

- All metric design available in two configurations, Indirect Gas heat and Classic with thermal fluid or electric heat

Options & Models

- Indirect Gas Model – Available in custom box lengths and custom widths

- Classic Model – 5m and 7m long cook lengths

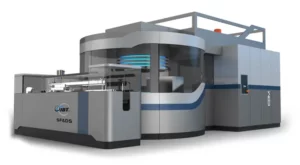

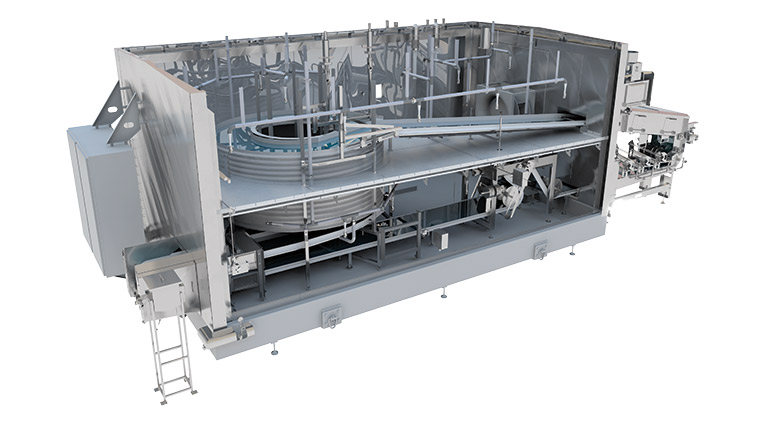

Stein GCO II GYRoCOMPACT® Self Stacking Oven

Our Stein GCO GYRoCOMPACT II Self-stacking belt spiral oven is the latest generation of forced convection spiral ovens from the company that introduced the first and most sanitary high capacity spiral oven system. Based on the innovative self-stacking FRIGoBELT® conveyor system, the GCO-II builds on the key features that made the GCO oven the highest capacity and most hygienic high temperature spiral oven in the world, while incorporating the latest in oven design and thermal processing technology.

Features & Benefits

- Designed for full cooking a wide variety of coated and uncoated products that require longer cook times to achieve the desired attributes.

- High capacity in a small footprint

- Generation II Vertical air flow with two variable speed circulation (VFD fans and Dynamic Air Control (DAC) for reversible up or down airflow to optimize product results whether coated or uncoated product

- Hygienic self-stacking stainless steel FRIGoBELT with variable mesh pitch for excellent cooking results and ease of sanitation.

Details

- Fully welded stainless steel enclosure with stainless steel thermal fluid heat exchanger

- Multiple heat transfer modes

- Variable mesh belt is standard

- Fully automatic Clean in Place (CIP) sanitation system

- Humitrol III automatic humidity (moisture by volume) control

- 4 ft. infeed section

- Electric drives

- ProLINK Controls with Allen Bradley PLC based HMI graphic interface

Options & Models

- Options:

- 80 mm Link Height, 15 to 20 tiers

- 100 mm Link Height, 12 to 16 tiers

- Models:

- Stein GCO-II-1000 TF GYRoCOMPACT Spiral oven with thermal fluid heat

- Stein GCO-II 600 TF GYRoCOMPACT Spiral oven with thermal fluid heat

- Stein GCO-II 600 IG GYRoCOMPACT Spiral Oven with Indirect Gas heat

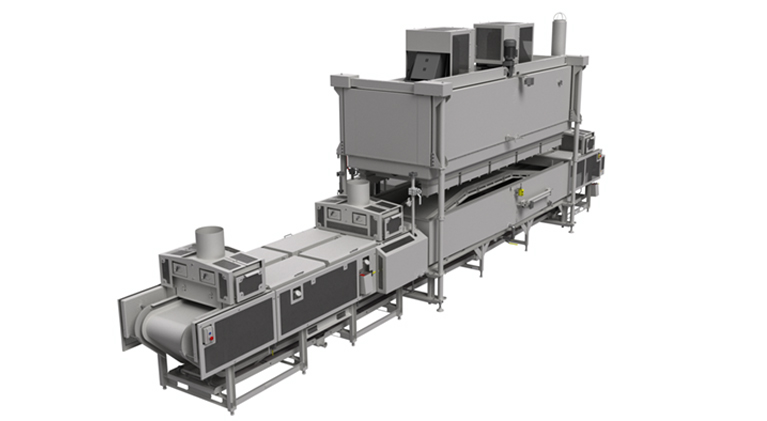

Stein JSO-C Jet Stream® Oven

Our Stein JSO-C IG Compact Jet Stream Oven represents the latest in thermal process innovation and provides a hygienically superior solution for mid-level processors who require a continuous process. The heart of our Compact JSO-C IG is the dual plenum air distribution (DPD™) system for even top and bottom cooking. As with our entire Jet Stream Oven family, the JSO-C provides superior product browning and is the perfect oven solution for a range of proteins including burgers, meatballs, and poultry items. We designed the Compact Jet Stream Oven for processors looking to reduce utility requirements, maximize production space, or upgrade from batch processing.

Features & Benefits

- Single zone, indirect gas heating eliminates by-products of combustion from the product zone

- Dual plenum air distribution system (DPD™) adjust top and bottom damper from a single point

- Clam shell hood design with automatic hood lift raises bottom nozzle plate, belt supports, and airflow structure

- Additional hood inspection door offers increased access to the upper fan plenum area

- Adjustable upper plenums from two to six inches above belt

- Automatic Clean-in-Place (CIP) system

- Two variable speed roof mounted VFD circulation fans

- Available with electric drives only

Details

- Mid-level capacity impingement oven designed for fully cooking a wide range of coated and uncoated food substrates with excellent browning capabilities

- Stainless Steel Construction

- Modular design, 16 ft. long cook zone, with up to four modules (64 ft. cook zone)

- Optional Infeed and discharge sections

Options & Models

- Stein JSO C (24-XX) Jet Stream Oven – Compact

- 24 in. (600mm) usable belt width

- 16 to 64 ft. long cook zone

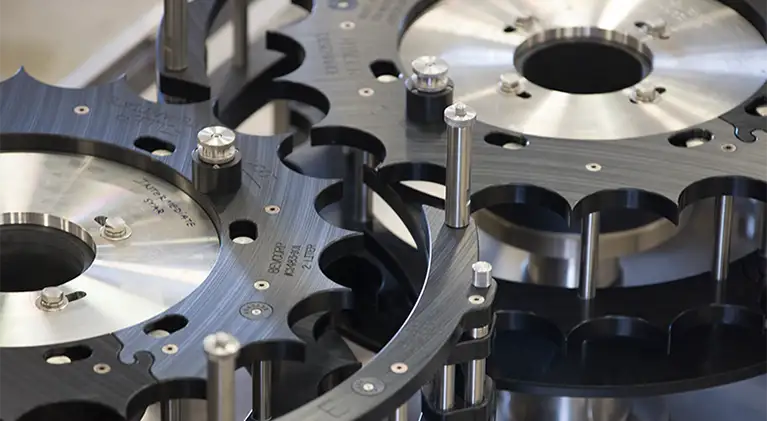

Bevcorp Custom Handling Equipment

JBT Bevcorp custom handling equipment and conversion packages are designed and manufacture for all brands of packaging equipment including Crown, H&K, Krones, and Meyer. We provide customer organization and storage solutions that promote your 5S initiatives.

Features & Benefits

- Emergency replacement parts available

- Lightweight and durable construction

- Quick-change parts with snap-in locators which require no special tooling

- Improved bottle handling with neck registration

- Color-coded parts for easier pairing and faster changeover

- Elevated base control allows the filler to run multiple bottle sizes more efficiently without elevating the filler bowl or closure system

- Mobile parts carts provide easy access and convenient storage solutions

- Made for all types of packaging equipment including fillers, seamers, and more!

Quick-Change System

Quick-change handling parts decrease changeover time, require no special tools and have snap-in locators for repeatable results.

Features & Benefits

- Organization and storage solutions promoting 5S initiatives

- Quick-change valve bells reduce changeover time

- Accelerating fingers with tool-less installation and removal

- Bowl elevating system quickly raises and elevates bowl to established preset height

- Economical

- Lightweight and durable construction

- Improved can handling

- Color-coded parts for easier pairing

Neck Handling System

Neck handling parts allow the filler and capper to run different size bottles without having to elevate the bowl or capper (neck handling through the filler and capper), providing greatly reduced changeover time, improved container handling and increased throughput. This system is designed with less potential for bottles to jam in the transfer area and represents the most cost-effective container handling option when running three or more bottle sizes.

Advantages

- Emergency replacement parts ship within 24 hours

- Lightweight with durable construction

- Improved bottle handling

- Color-coded by container size

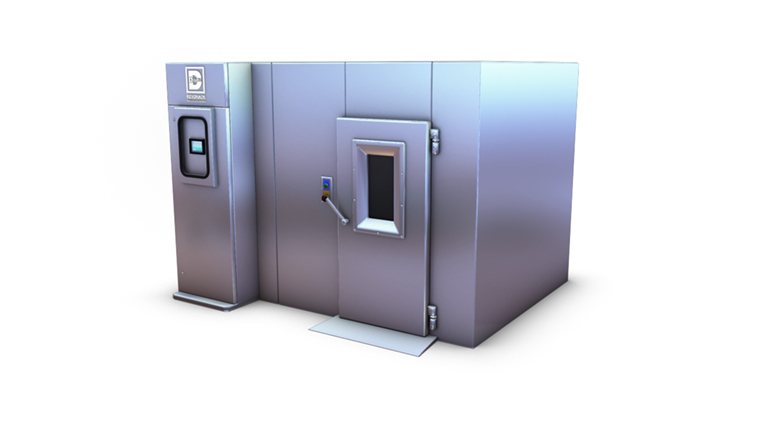

Missing Vent Tip & Tube Detection System

Our missing vent tip and tube detection system will detect the loss of vent tube tips and initiate an immediate stop sequence on fault

Features & Benefits

- Powerful high-speed laser accuracy up to 23 inches

- Sealed enclosure with glass window

- Custom mounting for all applications

- LED indicating status light

- Interface to existing controls

- Designed to prevent bio-contamination

- Integrated or stand-alone systems available for all rotary fillers

- IP67 wash down rating suitable for high pressure CIP processes

Convenient Storage Solutions

Handling Parts Carts

- Designed to hold a complete set of handling parts

- Lightweight with durable construction

- Complete labeling for quick identification of parts

- Reduce changeover time

- Mobile

- Easy wash down of parts after use

- Reduces damage to parts reducing replacement costs

Quick-change can bells, container handling parts cart, dual worm drive

Bevcorp Service

One Call. One Vendor. One Stop.

Single source accountability for your entire filling, blending, and closure operations

Call us for expert service at 440 954 3506.

Filling & Handling

With dozens of experienced technicians located throughout the U.S., we can dispatch to your facility at a moment’s notice. In addition to our standard service, we provide comprehensive filler evaluations, make recommendations for repair and improvement, and submit complete parts list pricing as part of our audit process.

Service Benefits

- Emergency and scheduled repairs

- Troubleshooting

- On-site training

- Parts installation

- Complete filler rebuilds on-site

- Filler installation, removal, and rigging

- Audits

- Specialized tooling

- Experienced field technicians and mechanics

- After-hours technical assistance, on-call 24/7

Seamers

Bevcorp can service, rebuild or overhaul your Angelus can seamer with quality parts, demonstrate how to maintain those parts, and ensure they are working properly. Ask about our Bev-U programs that can train your plant’s personnel on how to keep your can seamer in optimal condition with classroom and hands-on instruction.

Service Benefits

- Preventive maintenance programs

- Scheduled routine service

- Change part installation/change-over

- In-plant rebuilds

- Conferencing and consultations

- Audits

- Start-up assistance

- Angelus models: 60L, 61H, 62H, 80L, 81L, 100L, 101L, 120L

Training

With over 60 years of technical can seamer experience, Bevcorp is the smart choice for seamer training. We offer both classroom and hands-on training geared towards teaching mechanics, maintenance personnel and technicians with a comprehensive understanding of daily preventative maintenance, troubleshooting and critical point checks in the seaming process.

- Basic equipment setup and adjustments

- Double seam integrity training

- Equipment troubleshooting checklist

- Rapid changeover procedures

- Change parts/ can handling parts installation

- Double seam defect root cause – troubleshooting and analysis

- Seam setting

MicroBlend

Our field service technicians have extensive field repair experience. We can provide repairs, overhauls, preventative maintenance and upgrade kit installations.

Service Benefits

- Repairs and Troubleshooting

- Equipment overhauls

- Audits and system evaluations

- Installation of machine upgrades and kits

- Preventative maintenance for MicroBlend blending systems, Mojonnier carbo-coolers, and Mojonnier Flo-Mix systems

- Phone technical support

Audits

Mojonnier Carbo-Cooler & Flo-Mix Processors

Process engineers can audit systems to:

- Identify equipment capabilities

- Identify deficiencies in blending units, service utilities, and refrigeration systems

- Recommend upgrades to boost production capacities

- Improve operating procedures

- Diminish downtime

MicroBlend Processors

Process engineers can perform audits and evaluations to:

- Ensure system is operating at optimum performance level

- Verify calibration of components for flow, temperature and density integrity

- Evaluate operating procedures

- Provide software program backups

- Inspect and identify items that may need replacement or repairs

Capping Services

When your machinery is down or not performing at optimal efficiency, time is money. Bevcorp understands the value in having ONE SOURCE to call. That is why we have expanded our support to include setup, service, audits and trials for Alcoa/CSI and many other OEM capper brands.

Bevcorp now adds best-in-class capper technical support to our filler, blender, handling, and seaming expertise. With one call you can now access service and technical support for your entire filling line – saving you time and money.

Service Offerings

- Service and troubleshooting

- Audits for Alcoa / CSI Cappers

- Preventative Maintenance and Preventative Maintenance programs

- Rebuilds

- New closure trials and set-up

- Training backed by seasoned experts

- Case-by-case consulting and support for many OEM brands

- Skilled technicians with over 100 years of combined experience

- Preventive Maintenance

PRoCARE® Preventive Maintenance Programs – All Disciplines

Put your mind at ease by taking part in our annual preventive maintenance schedules for filling, blending, handling, seamer and capper parts and service packages.

Customer Benefits & Features

- Budget for the entire year

- Customize and plan preventive maintenance and service requirements

- Avoid emergency calls

- Standardize filler and blender maintenance

- Keep your equipment running at peak efficiency

Available Menu Items

- Filler, seamer, capper and or/blender audit

- One or two filler specific PM rebuild visits; includes parts and service

- One blender specific PM rebuild visit; includes parts and service

- One seamer specific PM rebuild visit; includes parts and service

- One capper specific PM rebuild visit; includes parts and service

Optional

- Non-PM items identified during audit as worn and in need of repair/replacement

- Independent performance inspections: handling parts and performance, DNC (Declared net content), filler, seamer and blender training, monthly visits/ “stop-ins”

Bevcorp Parts

JBT Bevcorp maintains one of the most extensive spare and replacement part inventories in the beverage industry today. Let our experienced sales support team identify and quickly respond to all your replacement parts needs. We carry parts for Bevcorp and legacy Crown fillers, Microblend and Micro2 blenders, designed and manufactured to OEM standards. We also supply parts for Angelus Seamers, and other closure parts. Replacement and repair parts are also available with design improvements and upgraded materials, such as stainless steel and hard chrome plate.

Parts Upgrades and Options

- Automatic Lubrication Systems

- Conversions for Multiple Can Sizes (such as 8, 12 or 16 oz. cans on one filler)

- CIP/CO2 Systems

- Product Line Enhancements

- Vent Tube Detectors

- Stainless Steel Designs

- Common Bases

- Award Winning Custom Safety Guarding

- Feed Screw Drive Conversions

- Air Conveyor Conversions

- Complete Major Assemblies

- Quick change Handling Equipment

Specialty items can be quickly produced with our extensive in-house machining capabilities.