Business Hours: Monday – Friday 7:30 a.m. – 4:30 p.m. Central Time

212700 Stainless Avenue

Stratford, WI 54484 USA

Toll free: +1 888 258 2789

Phone: +1 715 687 4332

Fax: +1 715 687 3225

Email: [email protected]

212700 Stainless Avenue

Stratford, WI 54484 USA

Toll free: +1 888 258 2789

Phone: +1 715 687 4332

Fax: +1 715 687 3225

Email: [email protected]

Midwest

Nick Burkle

Phone: +1 715 660 0217

Key Account Manager & Northeast Food/Bev

Rob Brown

Phone: +1 715 687 3080

Northeast Pharma/Biotech

Edgar Whitby

Phone: +1 267 660 7797

Southeast

Romeo Berthier

Phone: +1 559 474 0620

South Central & West Coast

Mike Tobey

Phone: +1 715 615 2095

Customer Care/Parts

A&B Customer Care

Phone: +1 715 687 3051

General Inquiries

Toll free: +1 888 258 2789

Phone: +1 715 687 4332

Fax: +1 715 687 3225

Email: [email protected]

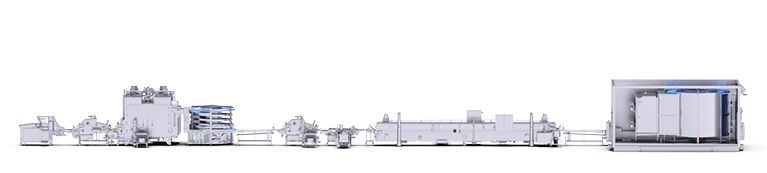

Our machines have a proven track record, trusted by numerous food industry businesses for years, when it comes to standardization and convenience technology.

Renowned brands such as Wagner’s pizza, Barilla’s sauces, and Wolf’s sausages are shining examples of the high-quality convenience food that alco processing machines consistently deliver. With their exceptional taste and appealing appearance, these products speak for themselves.

We understand that every business has unique requirements, which is why we pride ourselves on finding the ideal solution for your needs. To ensure a perfect fit for your product, we have established a state-of-the-art application technology center. Here, our team of expert technicians and product advisors will work closely with you to thoroughly examine our machines, leaving no stone unturned.

To expand the cooling capacity of Reinert Corp. in Germany, a tender was issued for a cooling system that could transport products without vibration and be easy to maintain and clean.

Jörg Timpe, Technology Manager for Reinert, remembers: “We wanted to expand in a manner that would save space and energy. In addition, hygiene, safety and quality are now more than ever top priorities in the meat-processing industry. The entire body of alco’s spiral cooler as well as all parts that would touch products are made of stainless steel (or have an FDA permit). Despite the minimal space, all components are easy to access and clean, which convinced us.”

Being a partner of alco for over 20 years now, HEIDEMARK stands for qualitative turkey processing, highest product safety, and highly efficient processes.

Here the company relies on the strong sales and engineering performance of alco. Thanks to short decision-making processes and a relationship based on mutual trust, alco manages to satisfy individual requirements and without further ado apply technical changes.

The coating line, which was acquired this year, additionally rounds off the repertoire of alco machines at HEIDEMARK. Fine, coarse, liquid, solid: Thanks to a variety of techniques the alco coating line applies coating media evenly, visually and economically to the product.

The special character of the start-up “BugBell” from northern Germany lies in the composition of the ingredients of their dog food, because here insects serve solely as a mono protein source.

In order to test the scalability of prototype handmade production to industrial, automated series production, the forming machine AFM and the spiral oven ASH were tested live on site at alco’s application technology center. The “BugKeks” were first to be given their shape in the forming machine and then achieve the ideal final consistency in the spiral oven.

Guided by alco’s product consultants and technologists and in close cooperation with the BugBell food specialists, productive and profitable insights were gained for both sides.

Our journey began in 1977 in Bad Iburg, inspired by the vision of Heinz and Gertrud Algra. Initially, we started as the general German distributor for a Dutch machine manufacturer, but in 1995, we took a bold step and started manufacturing our own food processing machines. Since then, we have been gradually expanding our portfolio, introducing one exceptional machine at a time.

What started as a small office has now transformed into a thriving and dynamic company. Over the years, we have experienced significant growth, but one thing has always remained constant: our unwavering commitment to crafting the best machines in the industry. Our dedication to innovation drives us forward, ensuring that we continuously deliver cutting-edge solutions to our customers.

From 1995 to 2022, the second generation of the family, including Nicole Algra, Thomas, and Isabelle Kleine-Ausberg, successfully led the company. However, on July 1, 2022, a significant milestone was achieved as alco joined forces with the JBT Corporation. This strategic partnership with JBT enables us to further enhance our dynamism and customer-centric approach in both regional and global food processing markets. By combining our technologies, we offer a unique and compelling value proposition to our esteemed customers.

Together with JBT, we are poised to drive even greater innovation, expand our market reach, and deliver unparalleled customer experiences. Our shared expertise and resources allow us to stay at the forefront of the ever-evolving food processing industry, ensuring that we continue to provide our customers with the most advanced and efficient solutions available.

At the alco application technology center in Bad Iburg, Germany, we prioritize meeting the unique requirements of your product. Our state-of-the-art facility serves as a hub for exploring the endless possibilities of food processing. Together with our skilled food technologists and engineering experts, we provide an environment where you can test and refine your food production processes using our advanced machines and equipment.

We understand the importance of practical trials in process technology to ensure flawless end products. That’s why we invite you to experience it firsthand. At our facility, you’ll have access to our comprehensive product portfolio, enabling us to collaborate on developing new products, streamlining production processes, and creating innovative applications that bring your ideas to life.

Moreover, we recognize the importance of convenience and accessibility in today’s digital age. That’s why we offer virtual meetings with our food specialists through live video sessions.

Whether you prefer an in-person visit or a virtual consultation, we are dedicated to supporting your journey towards excellence in food technology. Because after all, we believe that by combining expertise and cutting-edge technology, we can drive advancements in the food industry.

Together with JBT, we are poised to drive even greater innovation, expand our market reach, and deliver unparalleled customer experiences. Our shared expertise and resources allow us to stay at the forefront of the ever-evolving food processing industry, ensuring that we continue to provide our customers with the most advanced and efficient solutions available.

Where possible we can also provide on-site demonstrations in your own facility. To make reservations for the alco Food Tech Center, contact your local JBT office.