In addition to developing our own innovative products, we have dramatically expanded on our ability to provide customers with full-line technology solutions through a highly strategic, metrics-driven approach to acquisitions. Below are all of the brands that are now part of the JBT family.

A&B Process Systems

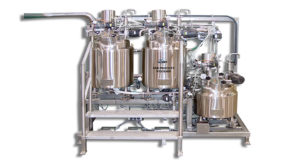

Turnkey solutions for advanced process systems stainless steel process vessels, process modules, skidded systems… and so much more.

A&B Process Systems is an industry leader in the design, fabrication, automation and installation of stainless steel process systems used in a variety of industries. From stainless steel process tanks and vessels, to process modules and skidded systems, we provide custom turnkey solutions that will help you meet or exceed your production goals.

We specialize in stainless steel custom fabrication of both industrial and sanitary process systems. The knowledgeable A&B Process Systems team will work with you to design, manufacture and install the best process system for your unique application.

Our manufacturing campus is home to an experienced group of process and mechanical engineers, ASME-certified stainless steel custom fabricators and fitters, process automation and electrical engineering specialists, and equipment installation and service managers who are ready to work with you to improve your processes.

Our campus also includes our exclusive Factory Acceptance Testing Center with full-service testing capabilities to ensure that your equipment will perform to your expectations. No challenge is too big, or too small, for A&B Process Systems.

From concept to completion, we are committed to reducing downtime, and completing your project in budget and on time. We are your complete fabrication and process systems partner. Upon completion of your project, we can offer you worry-free performance through contracted maintenance programs with our PRoCARE® program.

This customizable annual service agreement can include any or all of the following: inspection, cleaning and/or leak detection testing, replacements of wear components, and/or instrumentation calibration. We can also include a number of hours for automation and/or emergency service to be utilized as needed, etc.

But we are here to support you and your business, so beyond servicing our equipment, we can help throughout your plant!

- Tank & Vessel repairs

- Jacketing

- Agitators

- Modifications (vessel and/or piping)

- Preventative Maintenance

- Instrumentation Calibration

We hold the National Board R Stamp for repair and alterations of pressure vessels. Give us a call for help with your ASME pressure rated vessels!

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

More A&B Process Systems

• Find Career Opportunities at A&B

Related Resources

- Brochure A&B – Company Profile – EN

Recent A&B Projects

We’re proud to support these successful projects:

Tank Skids

ABOUT

The scope of this project was to add a second phase to a facility for Gene Therapy. Multiple Media Prep Tank Skids, Valve Assemblies, Inline Mixer Skids, TCU Skids, Buffer Prep Tank Skids, Components and Startup services were the major segments of this equipment.

SUCCESS

A&B Process Systems in-house capabilities, quick lead times and responsiveness lead to a great partnership and continuation of projects for this customer.

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

More Our Brands

- A&B Process Systems

- alco

- AutoCoding Systems

- Avure Technologies

- Bevcorp

- Cooling & Applied Technologies (C.A.T.)

- Double D

- DSI

- Formcook

- FranRica

- Frigoscandia

- Fresh’n Squeeze

- FTNON

- JBT

- JBT Control Systems

- MEPSCO

- Northfield

- PLF International

- Prevenio

- Prime Equipment Group

- Proseal

- Schröder

- SF&DS

- Stein

- TIPPER TIE

- Urtasun

- Wolf-tec

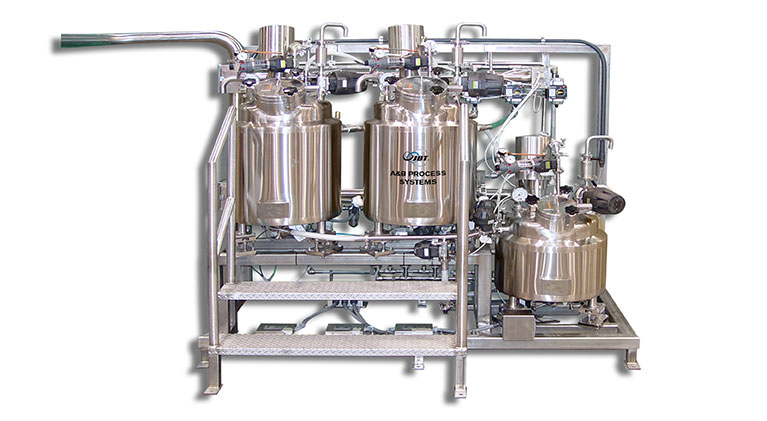

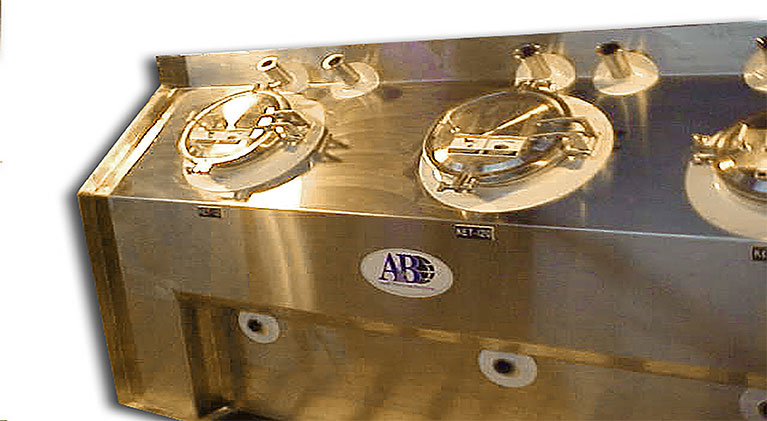

R&D Skid

ABOUT

A&B Process Systems provided a small scale R&D skidded unit for a small American pharmaceutical company recently bought out by a large brand name company. This unit was developed to test and work with infant and maternal nutrition.

SUCCESS

The strong partnership between A&B Process Systems and the customer has produced more design build projects and a solid understanding of their facility.

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

More Our Brands

- A&B Process Systems

- alco

- AutoCoding Systems

- Avure Technologies

- Bevcorp

- Cooling & Applied Technologies (C.A.T.)

- Double D

- DSI

- Formcook

- FranRica

- Frigoscandia

- Fresh’n Squeeze

- FTNON

- JBT

- JBT Control Systems

- MEPSCO

- Northfield

- PLF International

- Prevenio

- Prime Equipment Group

- Proseal

- Schröder

- SF&DS

- Stein

- TIPPER TIE

- Urtasun

- Wolf-tec

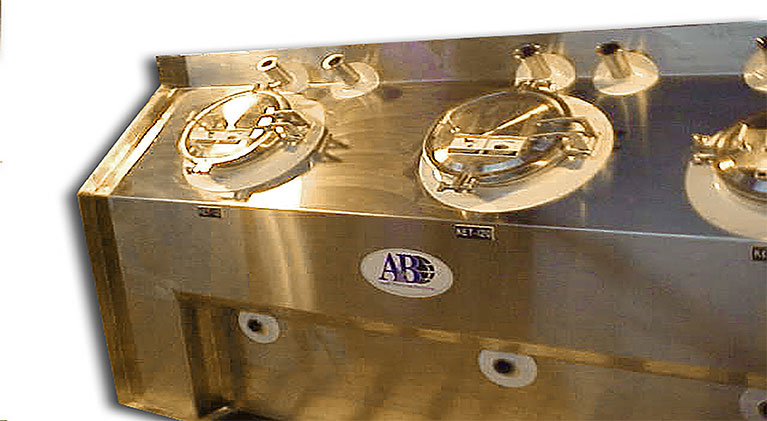

Silo Project

ABOUT

This project provided components and silo vessels for a multinational research facility. The equipment assisted with their R&D projects.

SUCCESS

R&D projects lead to founding solutions and allow customers to maximize on developed results. Giving the small scale of R&D equipment, they can make adjustments as needed when making a recommendation on factory setting equipment.

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

More Our Brands

- A&B Process Systems

- alco

- AutoCoding Systems

- Avure Technologies

- Bevcorp

- Cooling & Applied Technologies (C.A.T.)

- Double D

- DSI

- Formcook

- FranRica

- Frigoscandia

- Fresh’n Squeeze

- FTNON

- JBT

- JBT Control Systems

- MEPSCO

- Northfield

- PLF International

- Prevenio

- Prime Equipment Group

- Proseal

- Schröder

- SF&DS

- Stein

- TIPPER TIE

- Urtasun

- Wolf-tec

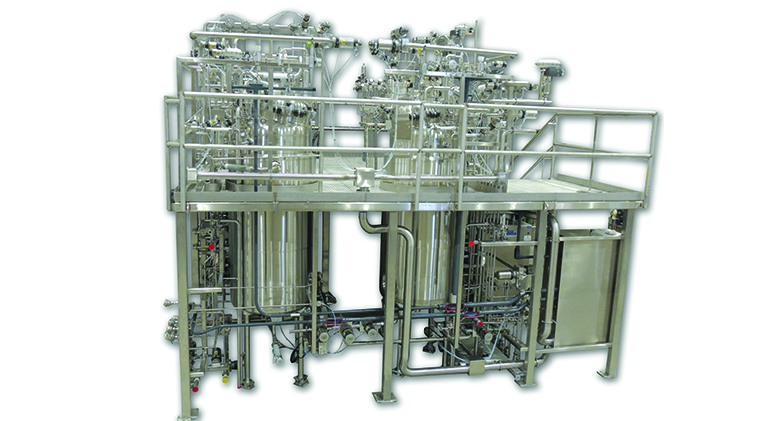

Bioreactor Skids, CIP Skids & Biowaste Systems w/ Installation

ABOUT

The project would feature the bespoke design of two bioreactor skids – one bioculture and another for dual use, with tanks, automation and platforms – as well as three Clean-In-Place (CIP) skids and two biowaste systems.

SUCCESS

The project from initial brief to final installation was a 14 month process, which involved 3-D modelling, weekly meetings through every phase of design and manufacture, leading up to final integration into the facility. A&B Process Systems carried out 3D modelling, manufactured and provided the reactors and skidded system, installation of wiring and electrical and acceptance tested after completion. Because of A&B Process Systems in-house capabilities, we’ve received a lot of positive feedback from the customer.

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

More Our Brands

- A&B Process Systems

- alco

- AutoCoding Systems

- Avure Technologies

- Bevcorp

- Cooling & Applied Technologies (C.A.T.)

- Double D

- DSI

- Formcook

- FranRica

- Frigoscandia

- Fresh’n Squeeze

- FTNON

- JBT

- JBT Control Systems

- MEPSCO

- Northfield

- PLF International

- Prevenio

- Prime Equipment Group

- Proseal

- Schröder

- SF&DS

- Stein

- TIPPER TIE

- Urtasun

- Wolf-tec

CIP and Tank Expansion

ABOUT

This project contained Media Formulation Tanks, Transfer Pumps, Components, Portable Single Tank CIP, Filler Station Transfer Panel, Platforms, Piping and Automation and Engineering Services. A&B Process Systems completed onsite Automation programming and FAT of the system.

SUCCESS

A&B Process Systems delivered this turn-key project before customers specified dates, making the hand off a smooth and well prepared measure.

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

More Our Brands

- A&B Process Systems

- alco

- AutoCoding Systems

- Avure Technologies

- Bevcorp

- Cooling & Applied Technologies (C.A.T.)

- Double D

- DSI

- Formcook

- FranRica

- Frigoscandia

- Fresh’n Squeeze

- FTNON

- JBT

- JBT Control Systems

- MEPSCO

- Northfield

- PLF International

- Prevenio

- Prime Equipment Group

- Proseal

- Schröder

- SF&DS

- Stein

- TIPPER TIE

- Urtasun

- Wolf-tec

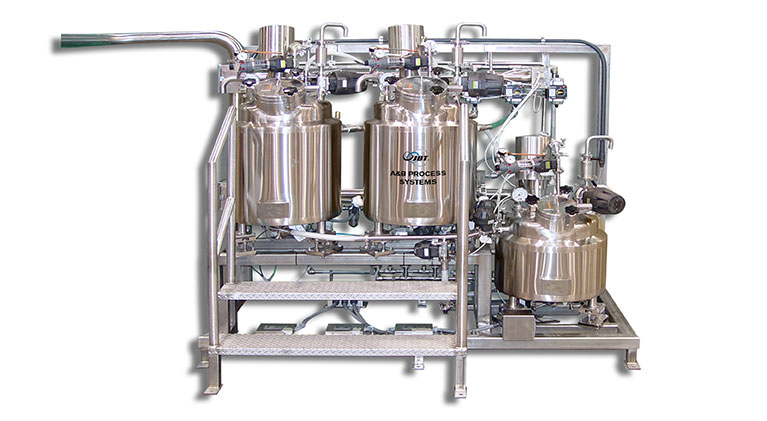

CIP Skid

ABOUT

An addition to the customers facility will make for a smoother, better functioning CIP flow. Two skidded tanks, piping, automation and engineering services and start up services provided the customer multiple wash recipes and options for their facility.

SUCCESS

This unit tied in to the customer’s existing system providing them a greater capacity and quicker turnaround.

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

More Our Brands

- A&B Process Systems

- alco

- AutoCoding Systems

- Avure Technologies

- Bevcorp

- Cooling & Applied Technologies (C.A.T.)

- Double D

- DSI

- Formcook

- FranRica

- Frigoscandia

- Fresh’n Squeeze

- FTNON

- JBT

- JBT Control Systems

- MEPSCO

- Northfield

- PLF International

- Prevenio

- Prime Equipment Group

- Proseal

- Schröder

- SF&DS

- Stein

- TIPPER TIE

- Urtasun

- Wolf-tec