Increase in Operating Time of Large Capacity Freezers

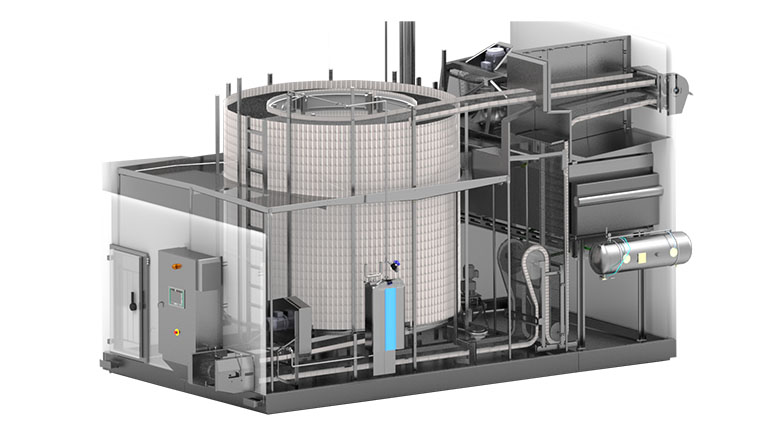

Imagine non-stop IQF production for six full days, with consistent yield and quality production. Imagine an airflow system that prevents debris buildup on the evaporator, saving you hours of cleaning and minimizing the risk of contamination. Inventor of IQF deep freezing in the 1960s, Frigoscandia now offers you the very latest advances in technology with the FLoFREEZE® with sequential defrost.

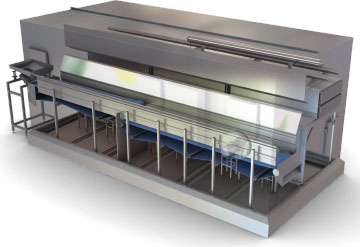

The FLoFREEZE IQF freezer from JBT Frigoscandia uses pioneering technology in the field of individual freezing for vegetables, fruits, fish and high-end IQF products. This technique is at the forefront of the industry, thanks to its versatility and the remarkable quality of its true fluidization. Discovering new, efficient and more economical freezing techniques is one of JBT’s goals.

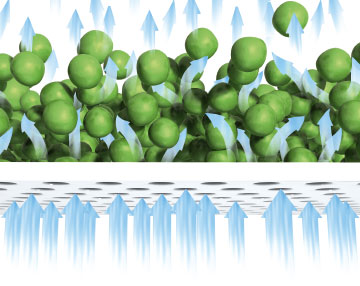

For large-volume productions, we have developed true fluidization applicable to an ever-expanding range of products, with extended uptime and improved efficiency. The Sequential Defrost technology ensures the optimal treatment of capacities up to 18 tons per hour for our Frigoscandia FLoFREEZE series-M range, with the possibility of easily modifying the air flow for products of different kinds and sizes.

Sequential Defrost ensures a minimum production time of six days between each defrost

Extended continuous operation

“Optimizing energy and costs remains a priority, which is why JBT has developed Sequential Defrost, a system that guarantees a minimum of 6 days of running time at full capacity before shutdown for defrost”, says Stefan Paulsson, Director of the FLoFREEZE product line at JBT Frigoscandia. “Defrosting a deep freezer is a lot of work, which is why we want to delay it as much as possible. Each defrost not only takes time, water and energy, but also causes production to stop. Longer run time increases production and efficiency. The FLoFREEZE Sequential Defrost offers safe and reliable technology that eliminates frost formation and reduces time wasted for cleaning and maintenance.

The FLoFREEZE IQF deep freezer can freeze up to 18 tonnes per hour of peas from +15 to -18 ° C, at an evaporator temperature of -40 ° C

Food safety and multidirectional airflow

With the current trend of consuming healthy products, the fresh fruit and vegetable industry is on the rise. Consumer habits have also evolved towards ready-to-eat products, freshly cut vegetables and fruits. Added to this is the growing demand for products from an ethical environment. In addition, producers must have high standards of hygiene and cleaning to avoid contamination and thus protect their brand.

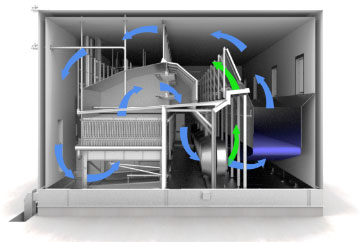

From their conception, our deep freezers are designed to minimize all unnecessary surfaces and avoid all the nooks and crannies that could constitute traps for bacteria. Our devices are designed for maximum accessibility without compromising their compactness. With the patented multidirectional air flow we reach a higher level of hygiene. This unique airflow prevents the amalgamation of debris on the evaporator fins, one of the most difficult parts to maintain, saving you hours of cleaning and helping to decrease the risk of contamination.

CONTACT US

We’re here to help every step of the way.SALES QUESTIONSGET SUPPORT

Philippe BARILLET – Sales Manager – France / Belgium / Israel / South Africa

[email protected] – +33 677 04 36 19

Victoria ORTILLEZ – Sales Manager – France / Belgium / Ukraine

[email protected] – +33 642 65 22 13

Kalid SAOU – Sales Manager Maghreb / Turkey / Egypt

[email protected] – +33 786 52 51 92

Françoise MOTARD – Sales and Marketing Support – South Region (France / Spain / Italy)

[email protected] – +33 615 75 54 58