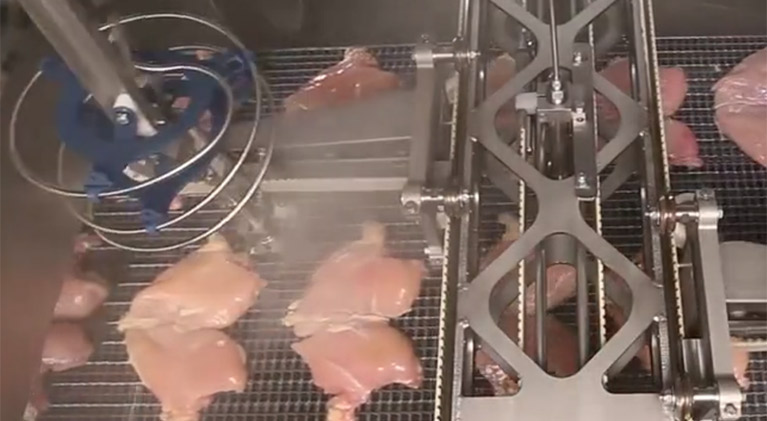

Our spiral oven serves for cooking and/or browning your products with steam, hot circulating air, or both. Its spiral belt guide allows plenty of room for products in our oven with a minimum footprint in your production facility.

Cooking, heating, browning: The spiral oven from JBT ALCO slowly and gently runs products through the cooking process utilizing a spiral conveyor belt that can be extended if required. That way, large quantities of your product will be cooked, and browned, or just steam cooked very evenly in the spiral oven with circulating air and/or steam. The smart spiral system makes optimum use of the available space so that maximum production capacity is achieved in the smallest possible space. At the same time, the distance between the individual levels and therefore the possible product height can be flexibly varied by selecting the number of levels. That way, even larger products such as whole chicken, burgers, or lasagna get their appetizing brownness and succulent consistency.

Perfectly suitable for meatloaf, whole chicken, burgers, nuggets, bacon, lasagna, pretzels

Need help developing your cooking process?

Seeing is believing. Book a demonstration of the alco Spiral Oven ASH today! With the world’s largest database with application tests and more than 60 years of experience in food processing, we know how to make the most out of your product in terms of taste, yield and consistency. The food experts at our Food Technology Centers help you develop your ideas or enhance existing ones. The tests can be conducted on our testing site in person or via live video link or as on-site demonstrations with our mobile lab equipment in your facility.

Features & Benefits

- Suitable for products of various sizes thanks to a selectable amount of levels and thus a variable product height

- Continuously adjustable production speed

- Targeted airflow in the system itself guarantees optimal and uniform heat transfer and browning

- Steam injection bars for setting the desired humidity

- Optional dew point control for maximizing yield

- Process temperature continuously adjustable up to max. 230 °C

Details

- Top-performance heating elements ensure efficient heat transfer. Choose between electrical, thermal oil, or steam-powered heating elements.

- Variable stage belt system allows for the selection of 5 to 10 levels

- Highly insulated housing design for preventing energy losses

- PLC control system controls the plant in a smart and user-friendly way through a touch panel with functions like recipe management, etc.

- An automatic, continuous belt wash system in combination with CIP nozzles in the interior of the oven ensures perfect cleaning

- Optional steam nozzles additionally heat the product through direct steam injection for the lowest weight loss

Options & Models

- The alco Spiral Oven ASH PRO is available in 400, 600, 700, and 1.000mm belt widths with a variable amount of levels