JBT for Poultry Primary Processing Success

Which came first: the chicken or the nugget? Obviously the chicken, and it took several steps to transform the live feathered fowl into a tasty, bite-sized, consumer-ready morsel.

JBT has everything you need to prepare a variety of birds for downstream processing – like coating, cooking, or packaging. Our equipment readily handles all manner of poultry:

- Chickens

- Turkeys

- Ducks

- Geese

- Other commercially-raised fowl and game birds

Better yet, your JBT poultry primary processing equipment can yield significant operational gains. Users of our machinery – typically large-scale intermediary poultry processors like you – frequently report meaningful benefits such as:

- Saving on labor. With greater labor efficiency, processors are able to reallocate workers to less dangerous, more fulfilling tasks.

- Increasing yield. The ability to get more meat off the bird, translates to major bottom-line boosts. JBT machines are the only ones available that can match hand yield.

- Improved food safety. Having reliable, automated, hygienic machines doing the work means accuracy, repeatability, and speed go up.

- Simpler and minimal maintenance and repair. Designed for ease of use and ownership, you’ll appreciate straightforward operation, cleanability, hassle-free part repair or replacement, and consistent accuracy over time.

- Smart resource usage. Efficient cleaning techniques and water reuse can cut a plant’s total water use in half – which is great for sustainability and cost controlling.

JBT doesn’t quit there, though. You’ll work with our team of skilled machine technicians and engineers to get the absolute best possible process and equipment set-up. You can think of them as expert consultants.

As they’ve spent a great deal of time in a lot of plants, they truly know their drumettes from their drumsticks and their scalders from their skinners. Identifying areas for optimization is a JBT specialty!

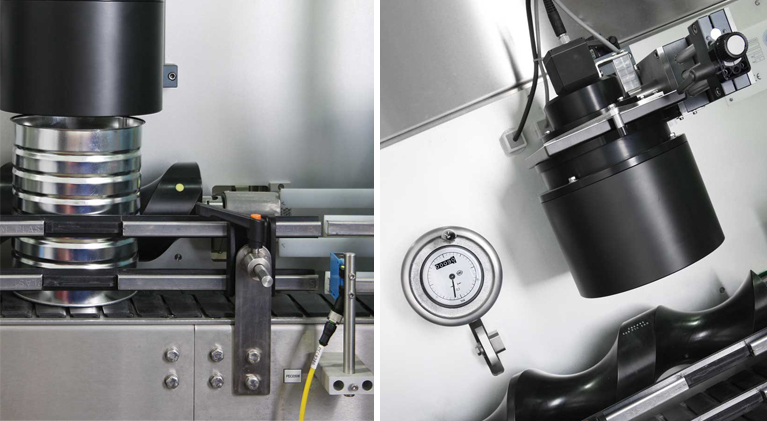

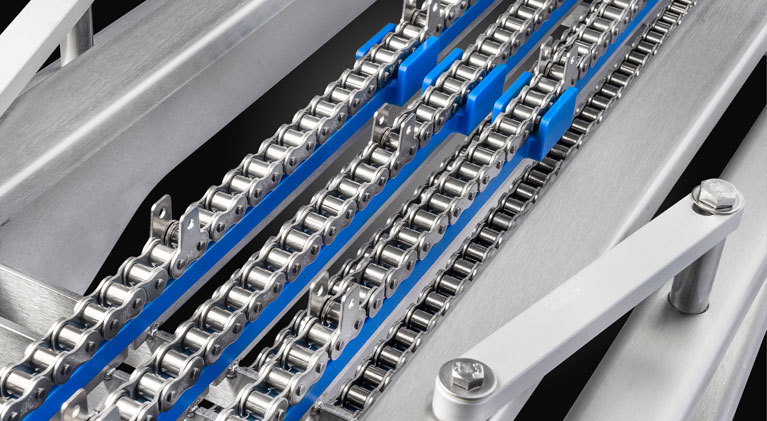

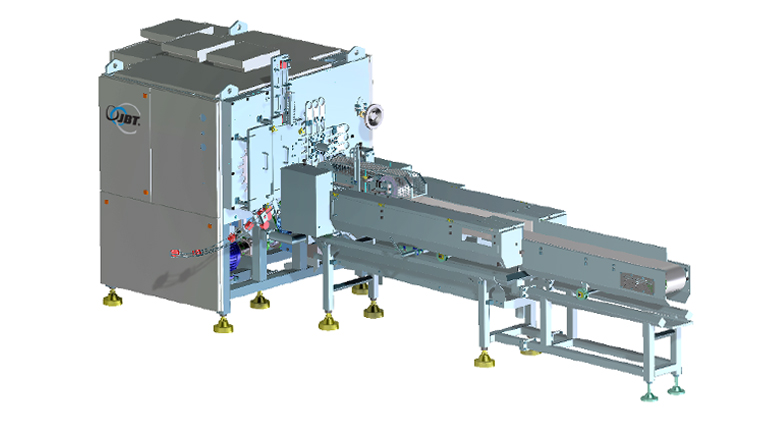

A JBT Machine Every Step of the Way

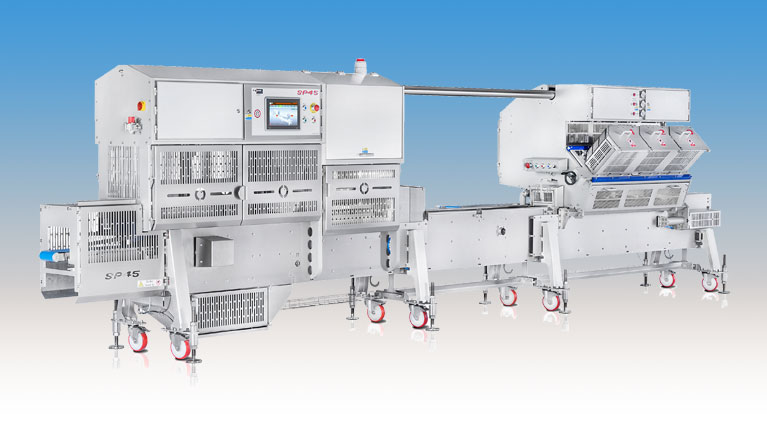

Poultry primary processing encompasses a long and diverse set of activities. With JBT equipment you’ll be able to do all of the following tasks and more:

- Receive delivery of live birds

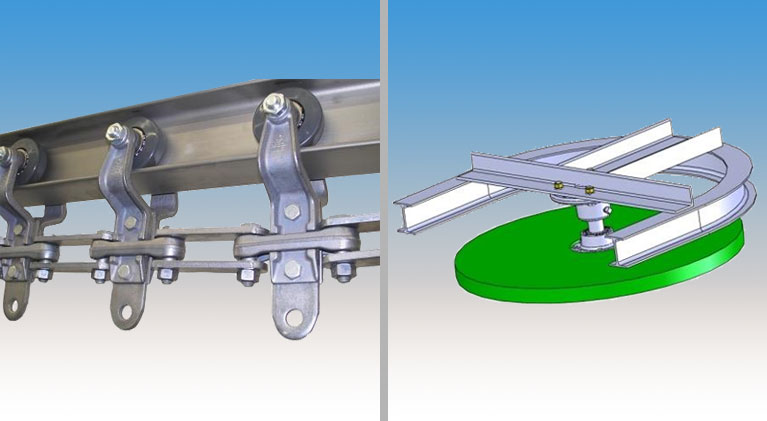

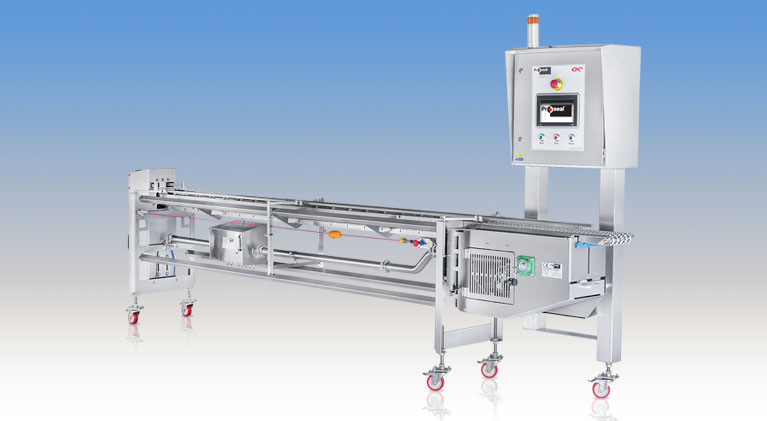

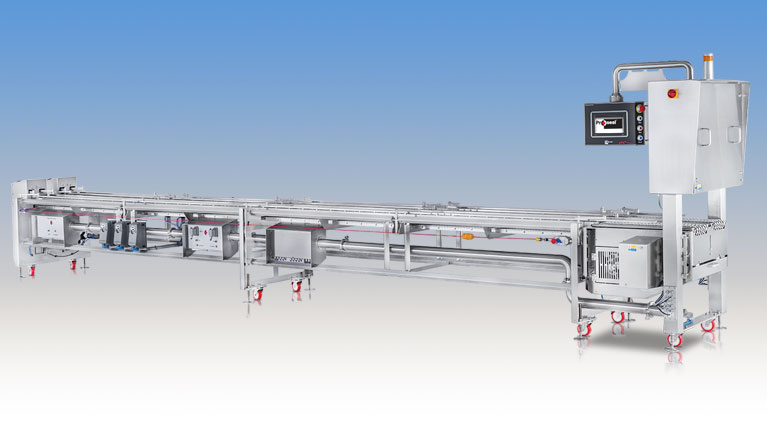

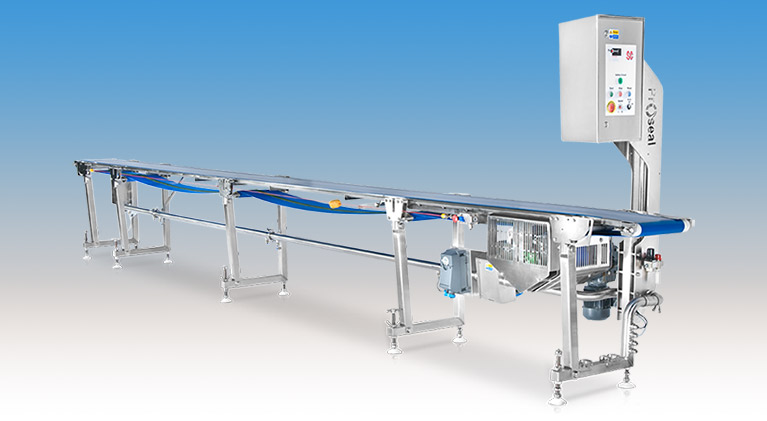

- Convey birds from station to station

- Stun and slaughter

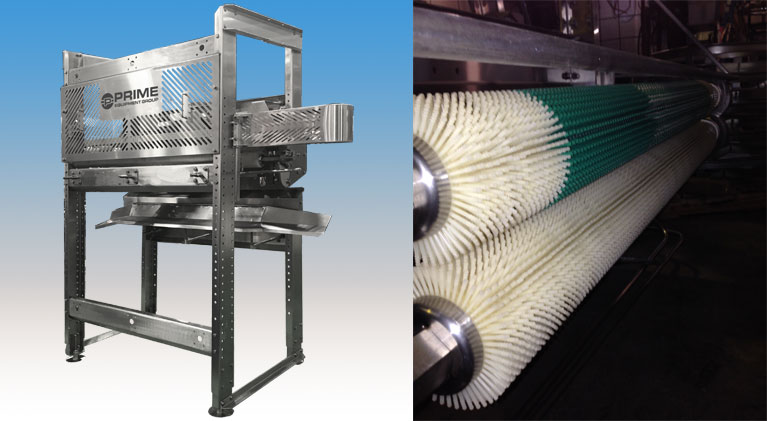

- Feather and offal screening

- Paw processing

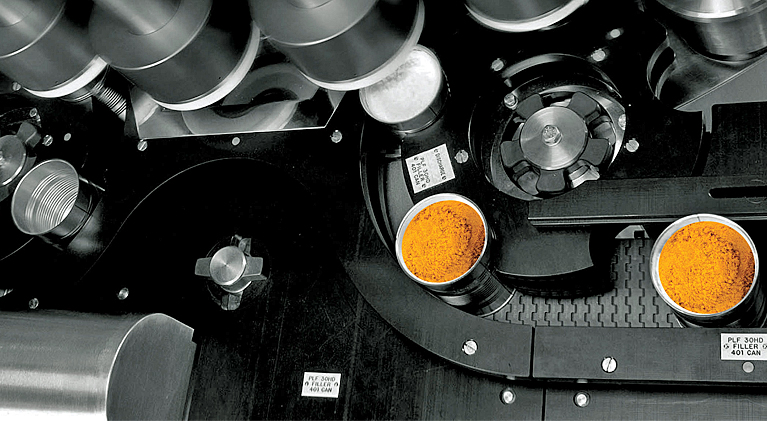

- Evisceration

- Trim and rinse

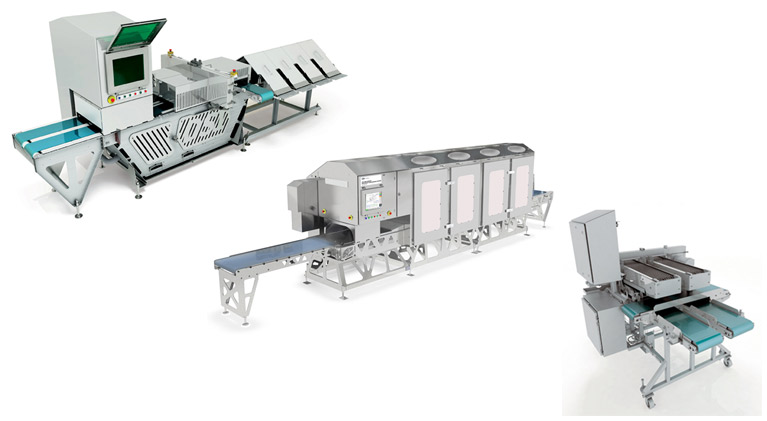

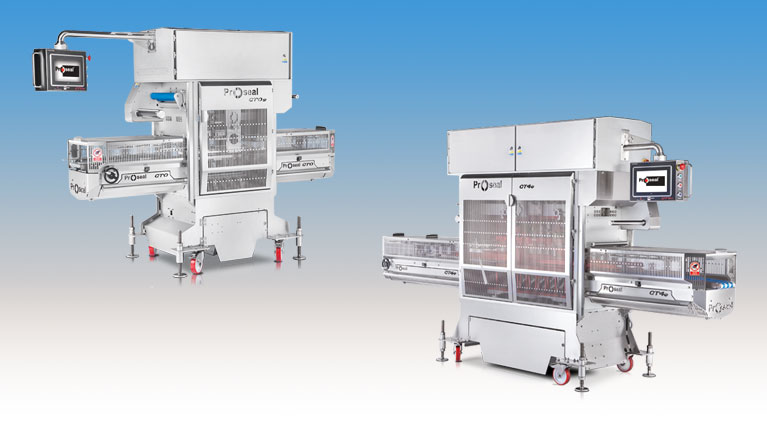

- Debone and cut up

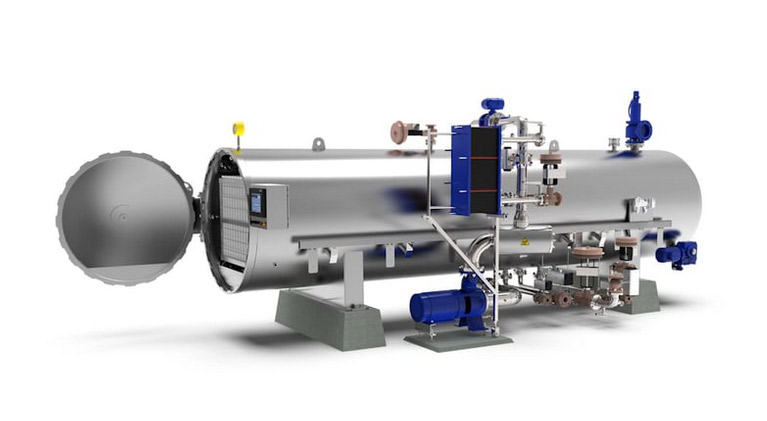

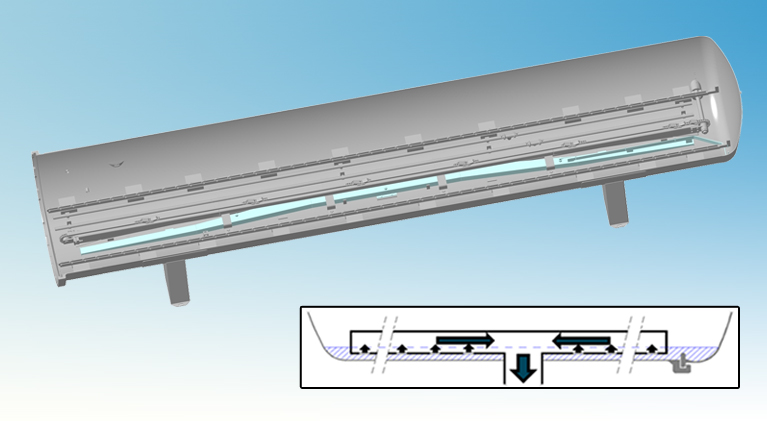

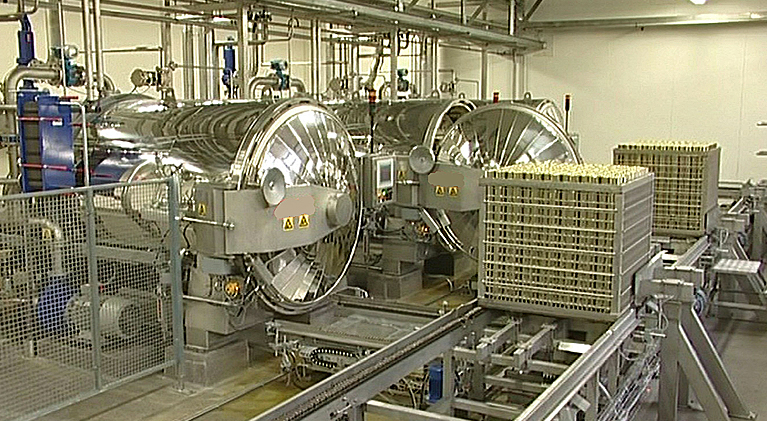

- Chilling and cold storage

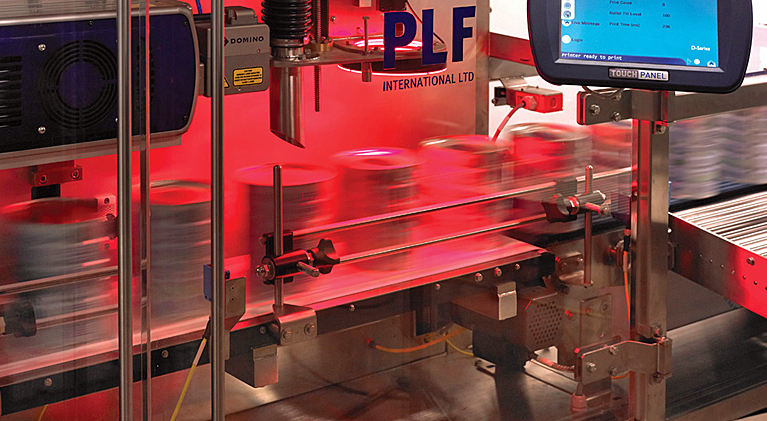

- Packaging

- Distribution

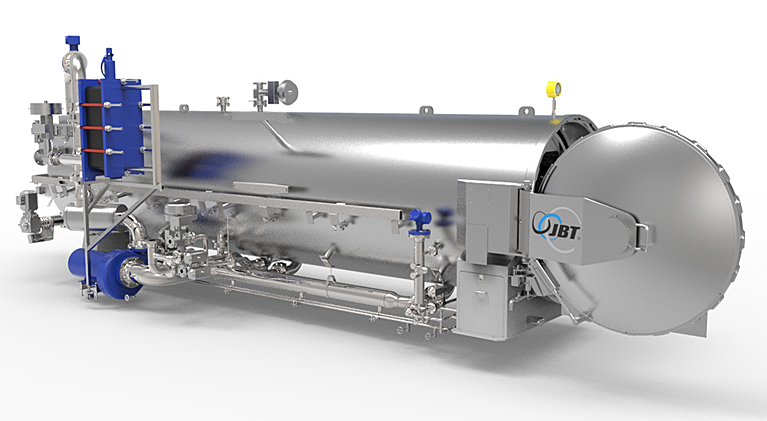

JBT’s extensive portfolio offers plenty of options for each process.

Features & Benefits

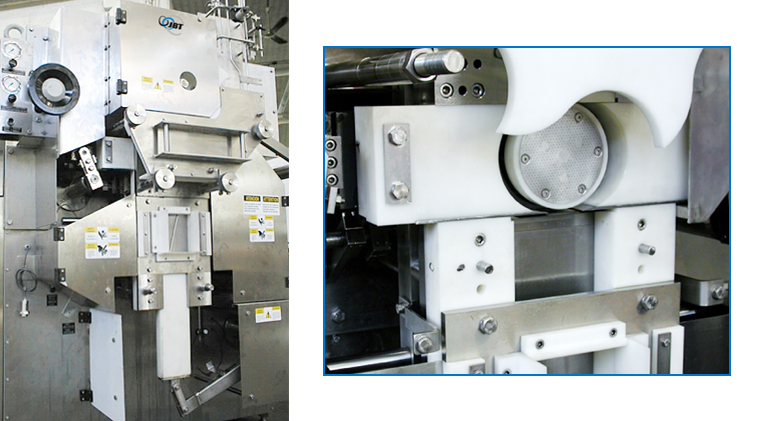

JBT’s poultry processing equipment is as stuffed with features and functionality as a holiday goose. All these capabilities make for food production that’s predictably fast, accurate, productive, and safe.

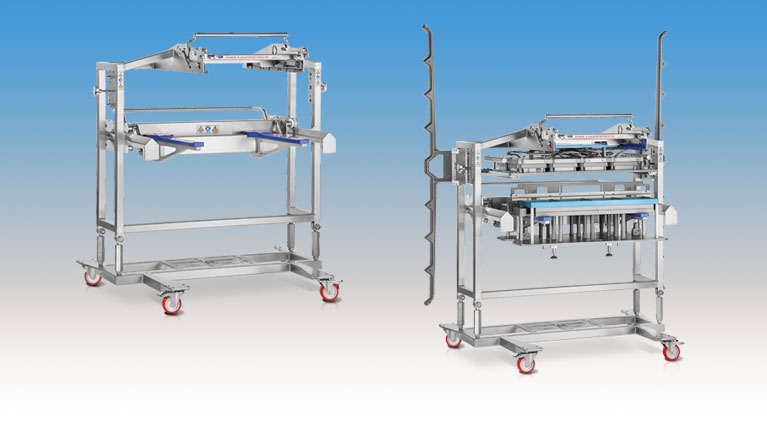

- Versatility – Customizable machines and configurations available to suit your requirements

- Efficient – No sick days plus redeployment of labor to more impactful positions for significant savings

- Eco-Friendly – Water reuse accounts for up to 50% water reduction

- Accurate – Maintains steady high-precision over time for quality products, optimal performance, and predictable operations

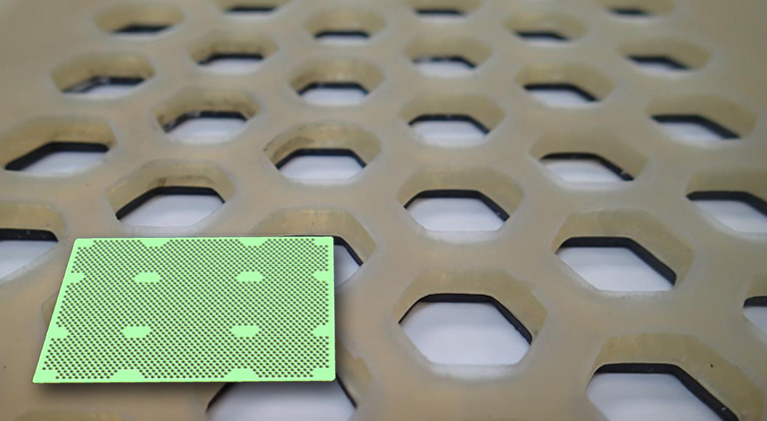

- Sanitary – Easier cleaning and reduced human involvement lead to fewer germs and increased food safety

- Speed – Faster throughput opens up opportunities for cost savings and additional income

- Ownability – Equipment designed to have the easiest maintenance and repair (M&R) possible

- Operable – Simple to use with intuitive controls

- Yield – Get the most meat off the bone for more product to sell from the same number of birds

- Durable – Built to last and perform consistently for years

- Safer – Worker and food security soar due to process automation

- Support – Global support staff available 24/7, year round

Have questions about these features – or how they can benefit your operations? Contact our team today.

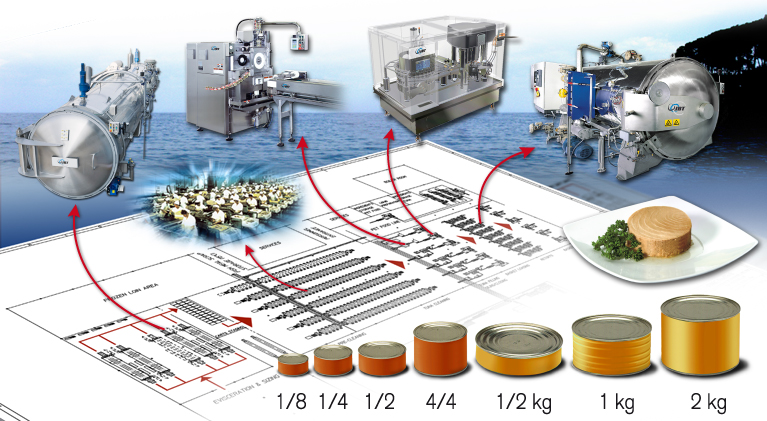

Prime Brands for Primary Processing

To consistently achieve top-quality results, you need machinery that’s first-rate as well. JBT only carries the best brands — ones that are on par with the level of outcomes you’re seeking.

Not only can you can count on JBT’s lines of exceptional solutions to be high performing and dependable, you can expect:

- Maximized uptime and productivity

- Efficient and safe operation

- Saving money and resources like water and energy

- Reduced waste and scrap

Trusted Brands

Every FoodTech Solution You Need, JBT Has

One reason customers flock to us time and again is our capacity to understand and address all their food production challenges and needs. JBT has a broad wingspan, so to speak.

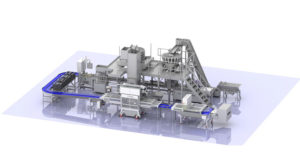

So, even though you’re looking into solutions for the initial poultry processing now, you’ll likely also require products and services for the manufacturing steps to follow. To accommodate your end-to-end operation, we’re a one-stop provider – offering an outstanding selection of unbeatable equipment.

You want to focus on feeding the world and turn a nice profit – JBT helps you do that like nobody else.

More Than Machines

You’ll quickly see that JBT can supply you with more than just picking, plucking, and portioning machines. With the quality and variety of our vast offerings, you can:

- Conveniently source equipment from one supplier

- Tailor your manufacturing assemblage to fit your needs

- Mix and match brands to get the exact setup you require

- Replace single machines within your existing production line

Add JBT’s upgrade kits, parts, maintenance, and training to the bundle and you’ll have an even more ideal solution.

Regardless of whether you’re buying one piece of equipment or many, JBT products integrate seamlessly with the rest of your operation.

Related Products

Birds of a Feather FoodTech Together

There’s no need to keep searching for a competent, comprehensive partner to help you conquer food production. JBT’s got what it takes to help your business thrive.

Taking the Long View

You’re more than a sale to JBT – you’re a valued customer! As such, we look forward to building a rich, enduring relationship. In our view, assisting you today – and for many tomorrows – is the best approach to doing business.

Over time, JBT’s able to internalize and anticipate your needs. This enables us to serve you more thoughtfully and comprehensively. It’s a terrific way to help you get the most from your JBT products and services.

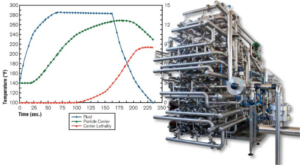

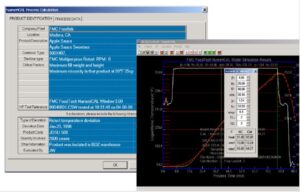

Test & Innovation Hubs

Use of our global Research & Technology Centers is a special and highly impactful perk of working with JBT. These amazing facilities – where you can try out machines, explore production configurations, perfect your recipes, access to technical expertise and data, and more – put mere test kitchens or labs to shame!

Expert Helping Hands

JBT’s been a food industry authority for over a hundred years. During that tenure, we’ve accrued volumes of knowledge and lifetimes of experience. We’re happy to share our learnings and insights with you!

Why do we encourage you to reach out? Because we’re well aware that being a titan of the food industry can be tough. Sometimes it just takes a little bit of extra care and attention from JBT to knock down barriers and resolve issues.

Contact us anytime with your questions, concerns, or requests. Let JBT’s talented crew be your go-to FoodTech resource.