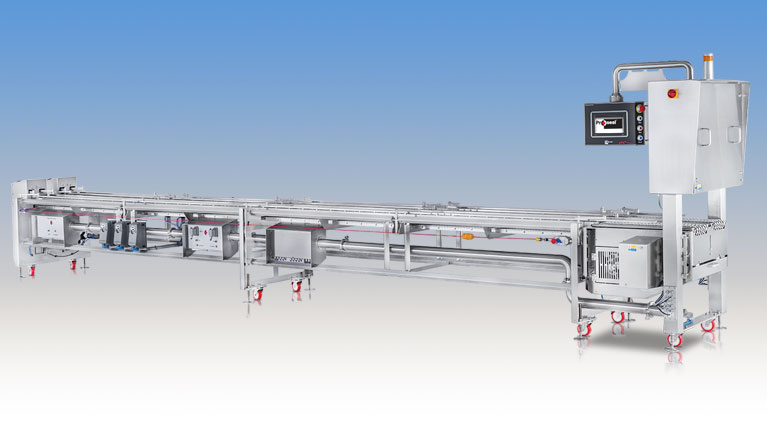

The Proseal OC Conveyor is an open-style, linear/twin-lane conveyor with an intelligent filler control system.A high throughput modular tray conveyor and filler control system, available in either single or twin-lane configuration. This range is designed to integrate with auxiliary equipment (such as tray de-nesters, fillers, multi-head weighers) and to feed filled trays seamlessly into any in-line automatic machine – including the GTe and GTs Range – to create a fully automatic production line, easily integrated with other production line equipment.It has throughput speeds of up to 60 packs per minute in continuous mode and 45 packs per minute in indexing mode with 0.5 second fill dwell in single lane, and 120 packs per minute in continuous mode and 90 packs per minute in indexing mode with 0.5 second fill dwell in twin lane.The OC Conveyor/Twin provides the flexibility required by food producers looking for a fully automated, turnkey production line with rapid product and tray type changeover in under five minutes.

Features & Benefits

- User friendly, menu-driven control panel with step-by-step prompts, error and status displays, and useful batch pack counter

- Recipe handling of machine settings

- Recipe driven auto machine set-up for pack change

- Modular design allows customer to specify conveyor length, width and tray pitch

- Variable pitch indexing conveyor will accommodate tray and lid dispensers, filling and weighing heads

- Fully integrated control of machine, tray and lid dispensers, filling and weighing heads

- A high specification conveyor drive system provides full control of the linear acceleration, deceleration and velocity of product movement and eliminates spillage

- QC button for one shot filling single pack

- Self-centring tray guides

Options & Models

- eWON a machine connection system to deliver real time data and error condition support, remote setup, and software upgrades, using a customer’s existing IT network

- Optional integration of peripheral equipment, such as: denesters, fillers, multi-head weighers, laser coders, labellers

- Automatic tray de-nesting

- Automatic lid pick and place

- Automatic lid over-capping

- Integrated air and electrical outlets along the machine length for auxiliary equipment

- Filler integration

- Labeller integration

- On-line weighing

- Servo driven conveyor

- Travelling motion filler heads

- Sale, Lease Purchase and Rental options available