JBT Schröder MAX 600/1200 – Compact Massager

MAX 600

The MAX 600 is a compact massager with integrated cooling and vacuum pump, representing the entry into the Schröder massager program. The ideal “plug and play” machine for batches up to 600 kg.

MAX 1200

The MAX 1200 is the next step in the compact class, making it the ideal machine for capacities up to 1200 kg – efficient and reliable. A range of options makes integration into any individual industrial manufacturing process possible.

Features & Benefits

- MAX 600/1200 control unit

- The intuitive user interface of the controller guides the program, guaranteeing safe, practical operation while storing all audit-relevant data.

- The functions in manual mode include manual control of all process parameters (for example: massaging, cooling and vacuum). In automatic mode, individual recipes can be selected and started automatically by setting a planned start or end point.

- The MAX recipe management system offers maximum flexibility as part of the automatic program sequences. It enables both the use of simple automatic programs with just a few individual steps and user-friendly input of complex recipes and sequences in up to five phases of the program.

- Pre-program – Bridges the time until the start of the main program (for example, initial massaging, keeping cool)

- Main program – up to three possible phases programmable:

- Part 1 – Linear sequence, step by step series of short programs with few individual steps

- Part 2 – Cyclical sequence, simplified entry of long programs using an adjustable number of repetitions of the individual steps

- Part 3 – Linear sequence, to complement of part 2, a final step-by-step sequence can be programmed

- Post-program – Bridges the time between the end of program and discharging (for example, temperature maintenance)

Details

- MAX 600

- Rated volume: approx. 790 l

- Fill level: approx. 75%

- Capacity: max. 600 kg product by manual loading

- Outer cylinder diameter: approx. 1000 mm

- Length, including drive: approx. 1850 mm (without vacuum suction)

- Width: approx. 1550 mm

- Height: approx. 2150 mm

- Discharge height: approx. 800 mm

- Electrical connection 3Ph/N/PE; 400/440V; 50/60 Hz or 3Ph/N/PE; 220V; 50/60 Hz

- Max 1200

- Rated volume: 1800 l

- Fill level: approx. 70%

- Capacity: 1200 kg

- Outer cylinder diameter: approx. 1300 mm

- Length, including drive: approx. 2400 mm (without vacuum suction)/approx. 4900 mm (with vacuum suction, BB600)

- Width: approx. 1400 mm

- Height (with base frame): approx. 2500 mm

- Drainage height: approx. 740 mm

- Electrical connection: 3Ph/N/PE; 400/440V; 50/60 Hz or 3Ph/N/PE; 220V; 50/60 Hz

JBT Schröder MAX 3000/6000 – Massager

MAX 3000 / 6000

The first class of massage units for large capacities – highly productive, powerful and reliable, can handle quantities of up to 3000 kg or 6000 kg.Designed in accordance with the in-line principle: Production lines with multiple units make ideal product flow possible without the risk of path crossing or cross-contamination.A wide range of options makes incorporation in any industrial manufacturing process possible. From automatic feeding by means of vacuum loading to program-controlled, intelligent Schröder FLOWMAX belt emptying.

Features & Benefits

- A wide range of enhancements enable the MAX massaging technology to be optimally adapted to the individual manufacturing processes. The MAX loading container optimizes the process cycle through the program-controlled pre-batching of products with marinades (brine) and additives. The vacuum loading enables efficient and hygienic product supply. Manual or automatic discharge is possible.

- In comparison with tumbler technology, less production space and fewer personnel are needed due to the automated processes.

- MAX technology: Increase in productivity

- Up to 50% reduction in processing times compared to the tumbler

- Increase in product yields

- Increase in slicer yields

- Significantly higher levels of system utilization compared to tumbler technology

- Energy savings thanks to increased efficiency

- Rationalization of the technological product flow (line capability)

- Integration in the Schröder VISMAX system

Details

- MAX 3000

- Nominal volume: 3600 Liter

- Fill level: approx. 84%

- Capacity: 3000 kg

- Outer cylinder diameter: approx. 1500 mm

- Machine length, including drive (without vacuum suction unit): approx. 3300 mm

- Machine width: approx. 1720 mm

- Height (with base frame): approx. 2970 mm

- Discharge height: approx. 960 mm

- Compressed air: min. 6 bar

- Electrical connection 3Ph/PE; 400/440V; 50/60 Hz

- MAX 6000

- Nominal volume: 7000 Liter

- Fill level: approx. 86%

- Capacity: 6000 kg

- Outer cylinder diameter: approx. 2000 mm

- Machine length, including drive (without vacuum suction unit): approx. 3375 mm

- Machine width: approx. 2090 mm

- Height (with base frame): approx. 3450 mm

- Discharge height: approx. 960 mm

- Compressed air: min. 6 bar

- Electrical connection 3Ph/PE; 400/440V; 50/60 Hz

Options & Models

- Standard version

- Thermo-plate and external insulation

- SCHRÖDER 10.4“ touch panel

- 100 / 160 m³ / h rotary vane vacuum pump

- Connections for cleaning nozzles

- Connection to customer cooling system (coolant: propylene glycol brine)

- Pneumatic feeding valve

- Large emptying flap

- Options

- Paddle with bulge for delicate products

- Load cells

- Product-specific feeding (lifting tipper, belt, priming tanks)

- Feeding container with batching software for producing a batch

- FLOWMAX automatic conveyor emptying system

- Dosing and spraying unit

Wolf-tec/Polar Massagers

The Polar Massager is the most capable, reliable and advanced system available for optimum curing, water binding and ingredient distribution in meat, poultry and fish products today. The Polar Massager has become the industry standard for the further processing of whole muscle products, including pork, beef, poultry and seafood. Processors have come to rely on the Polar Massager to reduce their operational costs and improve product quality. The Polar Massager’s patented paddle action provides the ultimate in even, quick dispersion of ingredients thoughout the whole muscle while maintaining product integrity. Over the course of three decades, our Polar Massagers have piloted an era of innovation and modernization in the meat processing industry. Through years of commitment, and research and development, our Wolf-tec / Polar brand has been recognized as the premium line of quality massagers.

Features & Benefits

- Small footprint saves floor space

- Jacketed and insulated tank for efficient product temperature control

- Improved product quality and food safety

- Industry’s fastest curing with no product holding time

- Quick disconnect “camloc” fittings for simple breakdown and cleaning

- Revolutionary passive massage system provides gentle, progressive action

- All product contact areas are ground flush and mirror polished for high hygiene

- Efficient, electro-mechanical drive provides smooth variable speed paddle rotation

- Minimal maintenance with self-lubricating drive chain

- Manually operated discharge chute for safe, reliable unloading of finished product

- Variable flow controlled manually by operator

- Large and easily accessed for loading, inspection and wash down

- Positive locking system with captive parts assures proper sealing

Details

- Our Wolf-tec Polar Massager features our patented Temperature Guidance System, which provides the perfect environment for your product. We apply heating or cooling exactly when needed to manipulate the internal temperature of the meat. This provides the fastest protein extraction, quickest massage times, and reduced curing hold times, all while preserving product quality

- The glycol jacketed Polar Massager has chilling capabilities to stimulate protein dissolving for a stable water-protein system. Simply, a better product with higher moisture retention. Our patented interior paddle design creates maximum mechanical stimulation, resulting in more tender products and lower purge in package without product damage

- Complementing the paddle action is the vacuum environment. Vacuum relieves the product of atmospheric pressure, which allows the marinade to more easily penetrate and distribute throughout the product

Options & Models

Models:

- Wolf-Tec / Polar Massager 2500 – Approximate capacity 2500 lbs. /1130 kg.

- Wolf-tec / Polar Massager 5000 – Approximate capacity 5000 lbs. / 2300 kg.

- Wolf-tec / Polar Massager 10000 – Approximate capacity 10000 lbs. / 4500 kg.

- Wolf-tec / Polar Massager 15000 – Approximate capacity 15000 lbs. / 6800 kg.

- Wolf-tec / Polar Massager 18500 – Approximate capacity 18500 lbs. / 8400 kg.

- Wolf-tec / Polar Massager 20000 – Approximate capacity 20000 lbs. / 9100 kg.

Optional Features:

- Modular vacuum loading system

- Can be integrated with load cells for effortless weight verification and optional automated brine delivery

JBT Schröder DT 2500/3700 – Continuous Tumbler

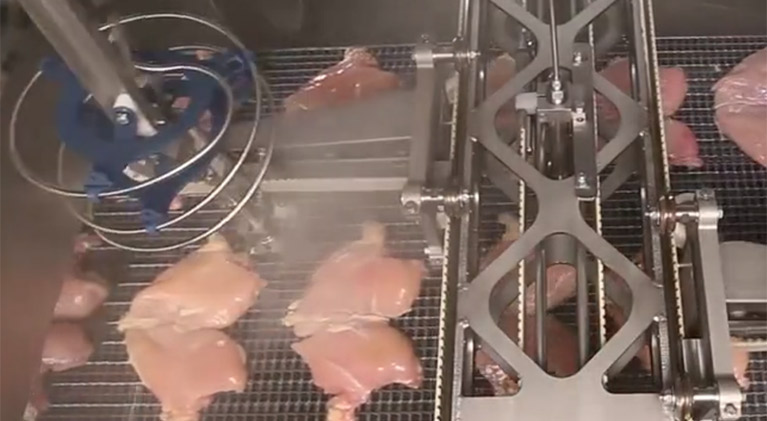

The massage and drainage drum for fresh meat, entirely made of stainless steel, is used for massaging the products and reducing surface brine. This brine is collected in a basin and can be transported back to the injector‘s filter unit via a pump.

Features & Benefits

- Machine housing and load-bearing elements are made of stainless steel, and the open design ensures easy accessibility for cleaning.

- Variable speed from 4 to 12 RPM, with selectable rotation direction.

- Drum length of 2500 mm or 3700 mm – excess brine can be effectively drained through the perforations without harming the product‘s surface.

- Product transportation is achieved through the drum‘s rotational movement. The adjustable drum slope ensures continuous movement of the product through the system.

- The product‘s throughput speed is influenced by the adjustable drum slope.

- The basin collects surface brine, and the pump unit transports it back to the injector‘s filter unit.

- The continuous tumbler can be equipped with casters for easy maneuverability.

- Smooth and residue-free brine supply pipes achieved by welding in a controlled atmosphere – the tumbler meets the highest hygienic demands.

Details DT 2500

- Drum length/drum diameter: 2500 mm / 800 mm

- Machine length: approx. 2520 mm

- Machine width: approx. 1245 mm

- Machine height: approx. 1825 mm

- Minimum product inlet height: approx. 1375 mm

- Minimum product outlet height: 860 mm

- Electrical connection: 3Ph/PE; 400/440V; 50/60 Hz

Details DT 3700

- Drum length/drum diameter: 3700 mm / 800 mm

- Machine length: approx. 3720 mm

- Machine width: approx. 1245 mm

- Machine height: approx. 1880 mm

- Minimum product inlet height: approx. 1430 mm

- Minimum product outlet height: 860 mm

- Electrical connection: 3Ph/PE; 400/440V;50/60 Hz

Portioning Systems/Slicers

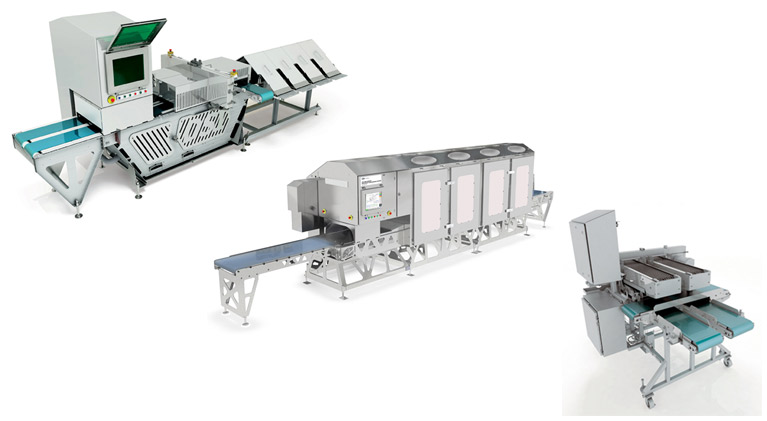

JBT DSI™ 812 Compact Portioning System

Waterjet portioning for even the smallest spaces

High Efficiency. Small Size. The DSI™ 812 Compact Portioning System is the perfect solution for processors who need the high accuracy, energy efficiency, and high throughput of DSI waterjet portioning but lack the floor space for larger models.

No Space? No problem. At under 2.5 meters long, and featuring the onboard JBT exclusive electric servo pump, the 812 can fit within the smallest footprint.

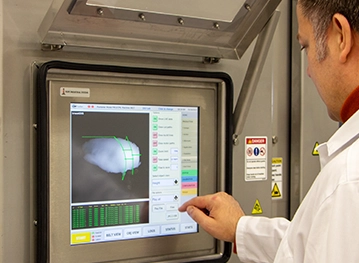

Smart

- DSI Q-LINK™ Portioning Software creates a unique cut strategy for each individual piece of raw product to maximize yield and profits

- Onboard scanner locates fat and determines shape, thickness and weight to create optimal cuts

- Computer positioned, high-pressure waterjets generate complex cut shapes while hitting weight and dimension targets

- Computer controlled consistency improves product quality by driving down human error

Compact

- Up to 70% less footprint requirement than similar waterjet portioners

- Onboard waterjet pump optimizes floor space while using up to 40% less energy than equivalent hydraulic systems and there’s no need to build a separate pump room.

- Measures in at only 2368mm X 1657mm (93.2” x 65.3”) 480VAC

Cost-Effective

- Everything you need without breaking the bank – a great option for small processors looking to automate portioning operations

- With automation, processors can redeploy manual labor from portioning to more skilled areas of the plant. The 812 can reduce hand trimming resources by up to 10 positions in select applications*

- In addition to labor savings, Improve your yield and bottom line with DSI-exclusive Q-LINK™ Portioning Software

CUTTING-EDGE FLEXIBILITY

Quickly generate complex tailor-made cut shapes in any form in one pass while still hitting weight and dimension targets with the DSI 812 high-pressure waterjet and the DSI Q-LINK™ Portioning Software. Get Cutting-edge flexibility!

CUTTING-EDGE YIELD

Maximize yield and profits by finding the optimal cut strategies for each piece of raw product with unique laser scanning technology and intelligent algorithms that locate edge fat and determine shape, thickness, and weight.

CUTTING-EDGE EFFICIENCY

Create a higher yield, maximize throughput, and improve product quality by switching from hand or semi-automated cutting to a fully automated and intelligent inline waterjet portioner with a footprint comparable to a blade cutter.

Experience the DSI 812 in action!

Are you curious how the JBT DSI 812 can make your portioning process more efficient, intelligent, and profitable? Book a demonstration with our DSI portioning experts at our Food Tech Center in Helsingborg, Sweden or Sandusky, US. Or, book an on-site demonstration in your own facility and production environment.

Guide: 7 ways to increase your portioning yield in one pass

You get examples of cutting patterns like:

- Cubes defined by weight.

- Multiple drop-shaped portions

- Weight, length, and width-controlled strips

Check out our latest DSI 812 Cutting Edge Demonstration Event

The demonstrations provides a platform for customers to interact with JBT’s application experts and learn about the new cutting programs and improvements as well as getting live demonstrations on the new DSI 812.

Are you curious how the JBT DSI 812 can make your portioning process more efficient, intelligent, and profitable? Book a demonstration at our Food Tech Center in Sweden, with our DSI portioning experts. Or, book an on-site demonstration in your own facility and production environment. Book Now!

Interested in growing your portioning business?

DSI™ 800 Portioning System

Additional DSI 800s Portioning Videos:

JBT, the Grade A Choice in Portioning/Packaging Systems

Efficiently and accurately cutting poultry, meat, and seafood to produce into portioned fillets, nuggets, chunks, strips, and fat-trimmed products

With the demands of today’s marketplace, wouldn’t it be nice to have a cutting machine that was fast, precise, accurate, and all those other capabilities on your must-have list?

Don’t settle for just wistfully pondering these things when you can actually have them all in a DSI system. JBT’s DSI 800 series portioning system is the solution to your diverse and changing needs.

Our DSI portioning machines are trimming meats in a variety of industries around the world. In fact, because they’re so flexible these portioners can handle:

- Cutting poultry into parts, fillets, medallions, strips, nuggets, and other complex shapes

- Slicing red meat into steaks and loins

- Producing pork bellies, trimmed ribs, tenderloins, and more

- Creating fish fillets, sticks, and more

Available with two, four, or six moving cutters — as well as optional stationary cutters and JBT’s patented jet blockers — the DSI 800 portioning system is the industry leader. In addition having the highest throughput and most compact waterjet portioning system, it boasts:

- Higher yields

- Reduced labor

- Smaller footprint

- More versatility

- Easier switch-overs

- Improved uptime

- Less maintenance

- Ergonomic

- Integratable and extensible

- Excellent support

The key to such incredible performance is the DSI 800’s cutting-edge technology. Each whole piece of meat is scanned as it enters into the machine. The system then automatically regulates the high-speed, robotic water-jet cutting head to create the desired portion or shape. Even better, the DSI Q-LINK™ Portioning Software provides a vast and growing library of portioning, trimming, and sorting possibilities.

With so many options, JBT’s portioning solutions give you the level of control you require to swiftly and smoothly plan for or respond to shifting consumer trends.

Features & Benefits

The DSI 800 from JBT comes with a full complement of features. It’s this functionality that enables you to quickly and safely produce fine food products every single day.

- Productive — Automated portioning and trimming increases yield

- Efficient — Requires significantly less labor than manual processing

- Compact — Requires only a small production space to provide high capacity output

- Uptime — Quick-Pass calibration facilitates operational and scheduling optimization

- Versatile — Programmable to accommodate a wide variety of changing products

- Intelligent — JBT iOPS® system monitors performance in real time and issues automatic notifications

- Adaptable — Can cut multiple shapes at the same time

- Customizable — Modular and easy-to-integrate systems to meet changing product demands

- High-yielding — Automated systems scans food and selects cut strategy for maximum yield

- Innovative — Advanced hardware and software allow for continually-improved capabilities and flexibility

- Support — Worldwide service, support, and resources

Contact JBT for more information on how these features can benefit your business.

Engineered for the Best Results

At JBT, we fanatically incorporate intelligent features and functionality into our equipment from concept to construction. Leveraging JBT’s years of experience, this thoughtful focus on detail also translates into advanced machinery that’s:

- Eliminating excess food waste

- Less vulnerable to unplanned service interruptions due to equipment issues

- Configurable and adaptable

- Compatibility with other food processing equipment

- Easier to operate

- Quicker to deploy

- Got a longer service life

- Got greater resale potential

- Made using the latest processes and best materials

- Designed and built to be durable

The net effect of all this? Exceptional value, ease-of-ownership, and the perpetual ability to streamline your production logistics. The clever features and functionality native to the DSI 800 can help you improve productivity, yields, costs, and product quality.

DSI Systems, Inc. — A Most Trusted Brand

You want equipment you can count on, right? We get it — wondering if your slicer is going to be on the fritz again makes it hard to operate effectively.

That’s why JBT only carries the top lines — like DSI. You already know their distinguished reputation and trust them to be on-point at all times. Our brands are highly regarded for their safety, efficiency, and cost and productivity advantages for good reason.

All Your FoodTech Solutions Under One Roof

Different products have different production needs. Simply having a lone portioning system just won’t cut it, so to speak. Fortunately, assembling the perfect processing line couldn’t be simpler — JBT has mastered the art and science of making this experience pleasant and less stressful.

As such, JBT offers a complete catalog of game-changing machinery and services. This is how we’re able to serve markets and applications as divergent as:

Regardless of whether you’re outfitting an entire production line or looking for a solitary machine — you’re in the ideal spot. JBT has the quality, selection, and flexibility needed to create a bespoke set-up that meets your specifications. So, you’ll be able to:

- Conveniently source all your equipment from one supplier

- Tailor your processing line to fit your requirements

- Mix and match brands to get an appropriate combo of machinery

- Easily replace or upgrade components of your existing assembly

- Respond to changes with agility

- More seamlessly scale your business

Upgrade kits, lubricants, and parts — as well as service, maintenance, and training — round out our offerings. Opting for the right bundle of products, services, and support can help you squeeze even more utility from your JBT equipment.

JBT, The Only FoodTech Partner You Need

With JBT on your side and covering all your food production needs — your search for a solutions provider is finally over.

A Modern, Customer-First Approach

As a JBT customer, you have our dedicated attention. We want your business to thrive and know that the best way for us to help is by forging a long-term relationship with you. This lets us serve you better now and in the future.

Testing & Innovation Hubs

One unique benefit you get with JBT is our Research & Technology Centers. Much more than test kitchens or food labs, these are facilities where you can try out equipment, explore production line configurations, fine-tune your recipes and techniques, and access technical expertise and data. Imagine all the ways this could improve your processing line as well as your bottom line….

JBT Specialists at Your Service

JBT’s been a foodtech titan for well over a hundred years. You’re encouraged to dip into this deep well of knowledge and experience. We provide this top-tier support because the food production business is tough — and sometimes a little helping hand is all you need to be successful. So, feel free to contact the experts at JBT for assistance or advice anytime.

JBT X-ray Guided Waterjet Portioning System

Our dual-lane X-ray guided waterjet portioning system combines the industry leading DSI™ 800 S series waterjet system with the new-generation Flexscan™ inspection system from the JBT Intelligent X-ray Inspection product lines.This new DSI X-ray system, focused on tougher pork applications such as pork ribs, determines the location of bones and other features, produces user-selectable products based upon bone and feature location, sorts the resulting products and reduces labor. Pork ribs and similar difficult meat products have traditionally been portioned or trimmed with 60,000 psi (4000 bar) pressure in waterjet systems pioneered by DSI. More recently, DSI developed and offers an 87,000 psi (6000 bar) waterjet solution, achieving superior cutting performance on tougher food products, allowing automated processing to reach new applications while leading to significant labor reductions and improved product quality.

Features & Benefits

- Reduces mist and noise from the waterjet via enhanced ventilation and jet capture

- Improves performance, service life and reduces maintenance with upgraded cutter assembly

- Provides flexibility and growth capacity with expandable modular platform, available in two, four, six or eight cutters

- Reduces space requirement and provides ease of operation based on direct integration with JBT X-ray system