The Gold Standard in Orange Juice.

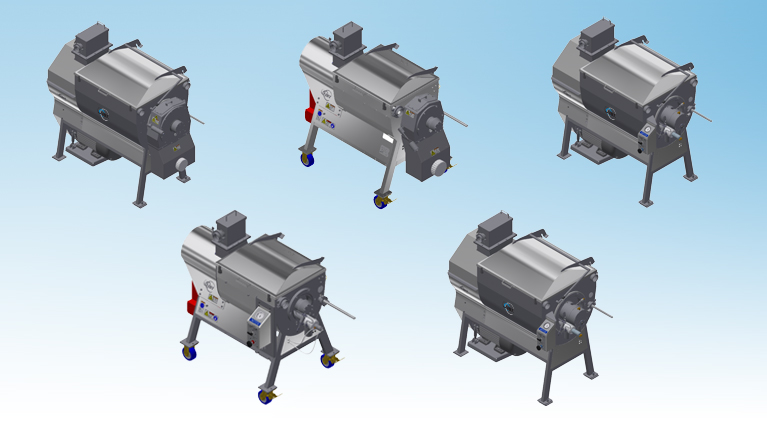

The Fresh’n Squeeze® 1800 sets a new standard for citrus juicing, delivering exceptional yield, taste, and reliability in a compact, commercial-grade machine. Powered by JBT Marel’s whole fruit extraction technology, it’s the juicer that defines what premium really means.

Gold = Good

The Fresh’n Squeeze® 1800 extracts up to 50% more juice from each fruit compared to traditional cut-and-press methods—thanks to JBT Marel’s whole fruit extraction technology. That means more juice, less waste, and better value with every squeeze.

But it’s not just about quantity. The 1800 preserves fresh-from-the-tree flavor by instantly separating juice from peel, seeds, and citrus oil. No bitterness. No off-notes. Just clean, vibrant juice your customers will love.

Its compact footprint makes it a perfect fit for hotels, restaurants, and retail spaces. And with the same industrial-grade technology used to process over 75% of the world’s citrus juice, it’s built for serious performance and long-term reliability.

Technology. Flavor. Reliability. That’s what makes the Fresh’n Squeeze 1800 the gold standard in orange juice.

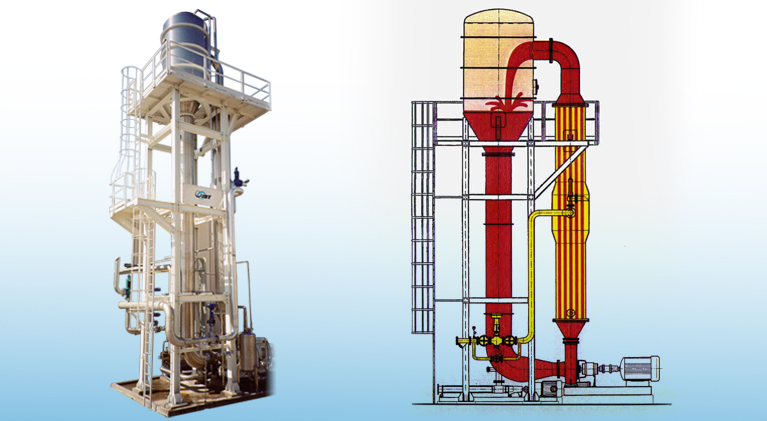

Whole Fruit Extraction: The Technology Behind the Taste

At the heart of the 1800 is our whole fruit extraction technology, the same innovation used in our industrial juice systems worldwide. This process separates juice from peel, seeds, and oil instantly, preserving the fruit’s natural flavor and nutrients.

- No bitter peel taste. No heavy citrus oil. Just pure juice.

- Low waste, high yield.

- Consistent quality in every pour.

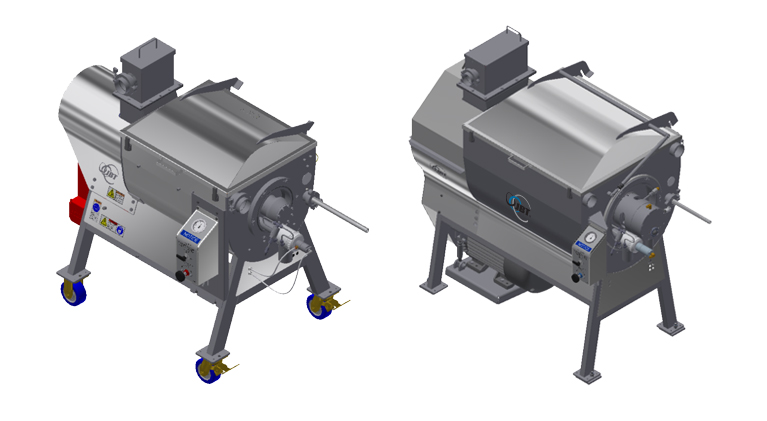

Compact Footprint. Big Performance

Designed for tight spaces and high expectations, the 1800 fits seamlessly into front or back-of-house setups. Whether you’re serving juice at a breakfast buffet or bottling it for grab-and-go, this machine delivers.

- 25″× 20″ footprint

- Handles up to one-gallon bottles

- Reverse function helps clear jams instantly

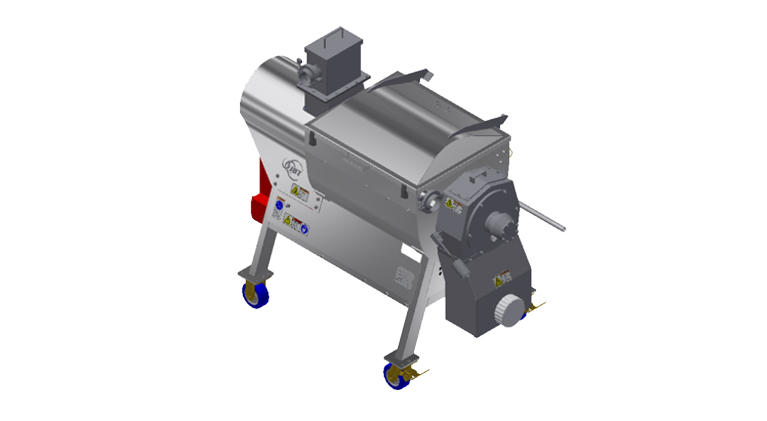

Designed for Speed. Built For Simplicity

With just six removable parts and hose-down cleaning, the 1800 is built for fast turnaround and minimal downtime. Your team spends less time scrubbing and more time serving.

- Quick disassembly

- Hose-down safe

- Built-in safety sensors and IEC plug compatibility

Juice More Than Oranges

The 1800 is versatile by design. It handles a wide range of citrus fruits, including oranges, lemons, limes, and tangerines, without needing additional juicing heads. And with four strainer tube sizes, you can customize pulp content to match your customers’ preferences.

- Single cup fits all fruit sizes

- Customizable pulp levels

- Switch citrus varieties with ease

Technical Specifications

| Feature | Specification |

|---|---|

| Juice Yield | Up to 50 oz/min (0.40 gal/min) |

| Throughput | 18 fruits per minute |

| Fruit Size Range | 2.5″- 3.25″ (63.5-82.5 mm) |

| Hopper Capacity | ~20 lbs. (approx. half a case) |

| Dimensions | 25″ W × 20″ D × 36″ H |

| Weight | 215 lbs. |

| Cleaning | 6 removable parts, hose-down safe |

| Certifications | NSF, UL |

| Warranty | 1 year from installation |

| Pulp Adjustment | 4 strainer tube sizes |

| Fruit Types | Oranges, lemons, limes, tangerines |

| Safety Features | Interlock sensors, rubber feet, IEC connector |

| Reverse Run | Clears jams and prevents stalls |

| Bottle Size | Handles up to 1 gallon bottles |

Make Every Orange Count

The Fresh’n Squeeze® 1800 helps you squeeze more value from every orange. It’s the smart choice for businesses that care about taste, performance, and profitability.

Experience the Gold Standard in Orange Juice

Let’s talk about how the 1800 can elevate your beverage program. Schedule a demo or request a quote today.