Improving costs and efficiencies by picking and transporting additional meat from bones and carcasses post-portioning

Reap the Most Advantage with JBT Meat Processing Equipment

In today’s competitive marketplace, it’s important to get the most out of your raw inputs and your machinery. This is how you’re going to keep cost/unit lower and boost the ROI for your capital investments. Downstream customers appreciate the product value for their money; back-office management loves the cost, quality, and performance metrics.

Does this ring true to your business? If so, the DSI Robotic Harvesting System from JBT needs to be part of your production lineup. This industrial harvester’s advanced technology:

- Reduces labor needs

- Speeds up your production

- Increases line productivity

- Cuts costs

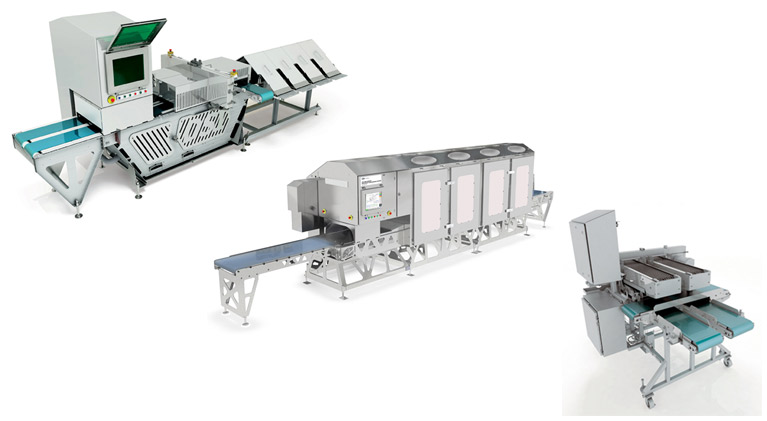

Better still, the DSI Harvester integrates seamlessly with your other processing equipment. It’s especially useful when paired with the DSI 800 Series Portioning Systems. Together, they form a robust product handling setup.

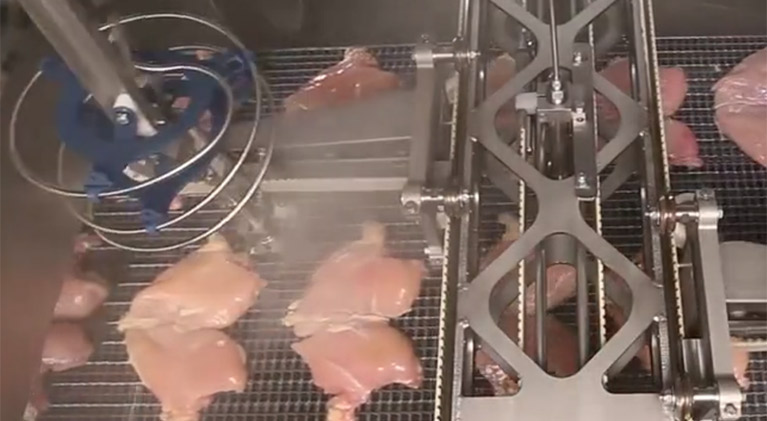

Using a pair of wash-down-ready SCARA robots equipped with custom vacuum end-effectors, the DSI Harvester picks off any meat left on the bones or carcasses after passing through the portioning stage. Harvested portions are then conveyed to your chosen line destinations. This minimizes waste and lost revenue opportunities as the trimmings can be leveraged in other products — like hamburgers or sausage.

This flexible platform is highly configurable and can manage most common poultry and red meat portioning applications.

DSI Robotic Harvesting Features & Benefits

As you’d expect, meat processing equipment from JBT comes packed with features. These capabilities make it possible for you to make high-quality food products every day — safely, swiftly, and cost-efficiently.

- Compatible — Industrial automation system designed to work with DSI portioners for best product handling and results

- Hygienic — Dual Stäubli TS2-60HE robots appropriate for use in wash-down environments

- Intelligent — Seamlessly integrates with Q-LINK™ portioning software for optimized automation

- Deployment — System installation and commissioning over a weekend for minimal downtime and fast rollout

- Compatible — Seamless integration with new or existing material handling networks increases system flexibility

- Robust — Dedicated air compression and filtration system to manage high-volume airflow

- Productive — Automated portioning and trimming increases yield

- Efficient — Requires much less labor than manual processing

- Customizable — Modular and easy-to-integrate systems to meet changing product demands

- Throughput — Automated systems scan food and select cut strategy for maximum output

- Innovative — Cutting-edge hardware and software allow for continually-improved capabilities

- Support — Worldwide service, support, and resources

Let us know if you have questions about how these features can benefit your business.

Perfect Pair: DSI Picking Machines & DSI Portioning Equipment

As mentioned, JBT harvesters work best when coupled with our DSI 800 and 800S Series of waterjet portioners. The new DSI Harvester system fully integrates with DSI Portioning equipment. A dynamic duo, these combined systems create a complete solution for hands-free portion cutting, sorting, and picking for protein processors.

With dual systems — each picking one item per second (for a total combined process rate of 240 per minute) — you can reduce the labor requirement by four people per shift. Additional labor savings happen when transporting portions with an integrated conveyor system, which are quickly and autonomous.

Built for the Best Results

Part of JBT’s mission is to create smarter products. When they work harder and more intelligently, your operations run better with significantly fewer resources (e.g., money, personnel, energy).

To this end, we engineer features and functionality into our equipment from the beginning. And, it pays off — for you. With our laser focus on sensible and strategic designs elements, you’re getting advanced technology that helps you:

- Eliminate unnecessary food waste

- Experience fewer unplanned service disruptions due to equipment issues

- Be more adaptable and resilient

- Operate equipment more easily

- Deploy systems more quickly

- Extend the service life of your machinery

- Get more money upon resale

We’re confident that the DSI Harvester’s clever construction will raise productivity, yields, and product quality while lowering expenditures. This means you’re bound to realize outstanding value, ownability, and potential for your business.

DSI, The Trusted Brand for Commercial Meat Processing Equipment

Having equipment you can count on is non-negotiable. Surprise downtime is an expensive and frustrating affair that’s best avoided. JBT gets it — we’re manufacturers ourselves.

It’s our motivation for only superior, well-regarded equipment lines. DSI is certainly one of those brands. With over 30 years on the scene, DSI is known for excellence and reliability. You’ll be safely and efficiently operating your DSI machines for years to come — and enjoying savings and other advantages all the while.

Your One-Stop Shop for FoodTech Solutions

A production line consisting of a lone harvester would be fairly ineffective. Luckily, JBT makes putting together a comprehensive processing line easy.

With our extensive portfolio of equipment and services, we serve a diverse range of markets and applications, such as:

It doesn’t matter if you’re buying one, 10, or 100 machines. JBT has the quality, selection, and flexibility required to build out the best assembly for your situation. This means you’ll be to:

- Conveniently get all your machinery from a single supplier

- Accommodate your specific processing line requirements

- Incorporate various brands to achieve the right equipment mix

- Effortlessly replace or upgrade individual pieces from your current set-up

- Nimbly address market or product changes

- More smoothly scale your operation

You can tack on upgrade kits, lubricants, and parts — as well as service, maintenance, and training — to optimize your outcomes. A power bundle of products, complementary supplies, and support always up the utility of your JBT machines.

JBT, a FoodTech Partner that’s a Cut Above the Rest

There’s no need to keep looking! With JBT on your team, you have all the solutions you’ll need to run your business.

A Better Way of Doing Business

JBT’s committed to helping your business succeed. That’s why we work so diligently to establish a collaborative relationship that will last for years beyond a near-term sale. This approach lets us get to know your business more profoundly so we can provide you with even better service and greater overall value.

Research & Innovation Hubs

Something you won’t get elsewhere — JBT’s incredible Research & Technology Centers. These learning hubs are far more than test kitchens or food labs. They’re places where you can try out machinery, consider different processing configurations, tweak your recipes and methods, and get technical expertise and data. All of these things can be a boon to production and profits.

JBT Experts At Hand

For over a century, JBT’s led and innovated the FoodTech industry. We’ve accrued a massive amount of knowledge and experience in that time and are happy to share our information and insights with you. We offer this premium support because we want to help ensure your business thrives. Feel free to reach out to JBT anytime for assistance.