Reach new heights in terms of efficiency and precision with the most advanced automated suspension technology on the market

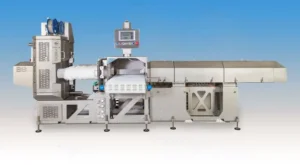

At JBT, we’re committed to making life easier for our food-industry partners by creating processing equipment that is flexible, reliable, and highly integratable. The TTStick product line combines state-of-the-art automated suspension technology with highly-intuitive, user-friendly controls to enable the efficient production of portions or strings of sausages.

Joined with TIPPER TIE automated double clippers, the robust TTStick (and SwiStick XXL, for heavier, larger sausages) safely and precisely suspects sausages across a wide variety of casing types, calibers, and string lengths. Designed to minimize downtime and reduce labor and maintenance costs, this system empowers you to reap the benefits of automated, high-capacity production while streamlining and simplifying your operations.

Features & Benefits

JBT’s TTStick automated hanging, tying, and packaging system was designed and built by our experts to maximize flexibility and productivity. With intuitive controls that offer superior convenience and safety and an ultra-hygienic, easy-to-maintain design, you can boost production while reducing the need for downtime and costly maintenance.

Here are some of the system’s stand-out features:

- Versatile applications – The TTStick system is ideal for the efficient production of dry sausage, smoked sausage, vegan sausage, and raw/frozen/refrigerated pet food.

- High-capacity, flexible production – The system can easily handle sausages in plastic, fibrous, and collagen casings. The base model can accommodate calibers from 20 mm to 120 mm with a maximum sausage/string length of 800 mm.

- Unrivaled efficiency – The TTStick has the power to produce up to 100 loops per minute, depending on the product. To change the loops or clips, only the string loop housing needs to be opened, which doesn’t require disconnecting the system. This enables new casing to be added while the machine is in operation, leaving production virtually uninterrupted.

- Reduced labor costs – The system’s single-operator design empowers you to achieve high-capacity production without the need for additional operators.

- User-friendly controls – The TTStick line is powered by maintenance-free servo motors and is equipped with an advanced PLC control system operated by an intuitive touch screen. All settings can be stored in the program for quick recall. This design maximizes convenience, hygiene, safety, and efficiency.

- Simple cleaning and maintenance – Smooth stainless-steel surfaces and robust components allow fast, hygienic cleaning and minimal maintenance and service, minimizing downtime and the total cost of ownership. Imminent maintenance requirements are communicated to the operator on the system’s touch screen.

- Advanced safety features – The system is equipped with an integrated safety control system that monitors and stops production when necessary, placing the TTStick, clipper, and stuffer into a standby position in event of machine error.

TTStick Specifications

The TTStick offers producers high-powered performance combined with simple operation and maintenance requirements. With the ability to accurately process units of a wide range of sizes and casing types, the system can be easily integrated into your existing setup, streamlining your operations and offering the flexibility you need to meet your goals.

- Weight: Approximately 850 kg

- Capacity: Up to 100 loops per minute

- Caliber range: 20 mm – 120 mm

- Sausage/string length: 130 mm – 800 mm (or up to 1,700 mm with the SwiStickXXL)

- Smoking stick size: 800 mm – 1,250 mm (easily adjustable)

- Sausage weight: 0.1 kg – 4 kg

- Protection class: IP65

- Fuse protection: 10 A at 3 x 400 v / 50 Hz

- Power consumption: 3.7 KW

- Air pressure / air consumption: 6–7 bar / .8 Nm 3/h

Read a case study on TIPPER TIE customer Carniprod here.

FAQs

What is the difference between the TTStick and the SwiStickXXL?

Both models are designed to safely and effectively suspend sausages in plastic, fibrous, and collagen casings and accommodate calibers from 20 millimeters to 120 millimeters. However, while the TTStick accommodates a maximum sausage/string length of 800 millimeters, the SwiStickXXL can handle significantly longer maximum sausage/string lengths of up to 1,700 millimeters. That’s why the SwiStickXXL is the ideal choice for producing heavier, larger sausages.

What options and accessories are available for this system?

The TIPPER TIE double clipper can be fitted with a swivel tube or a parallel turret. These options enable the casing to be changed without opening the upper section of the TT1815 or TT1512 to achieve even faster changeovers. With the parallel turret, while one casing string is running in the fill-in position, the free filler tube swivels up and a new casing is fitted and swiveled into the integrated casing brake holder. Changing a casing only requires about two seconds of standstill time for the filling machine, enabling virtually uninterrupted production.

Do you provide training and maintenance for this system?

Absolutely. JBT is dedicated to ensuring that you get the most out of your machine. That’s why we provide specialized operational training on how the system works and how to customize its performance. Due to the high-tech design and construction of the TTStick, you won’t need to perform the maintenance processes required of most machines of this caliber. However, at JBT, we maintain our PRoCare promise to ensure that you get the ongoing services you need to keep your operation running smoothly and effectively.

Join Us At Our State-of-the-Art Research Centers

JBT does more than produce high-tech machinery. We also want to share our vision and innovative approach with you. When you partner with JBT, you get coveted access to our Research & Technology Centers, where you can test the newest equipment, experiment with various system setups and configurations, get your questions answered, and work directly with the greatest minds in FoodTech.

JBT – A True Leader in FoodTech

For over a century, JBT has been out on the frontiers of the FoodTech industry, constantly developing and manufacturing new, innovative technologies and solutions for our valued food-processing partners around the globe. But we’re more than an equipment provider. When you choose to work with JBT, you become part of our family. Our success depends on your success, and our experts are available around the clock to offer industry-leading support as well as ongoing maintenance services, replacement parts, upgrade kits, and more.

Contact us to learn more about our services and become a partner today!