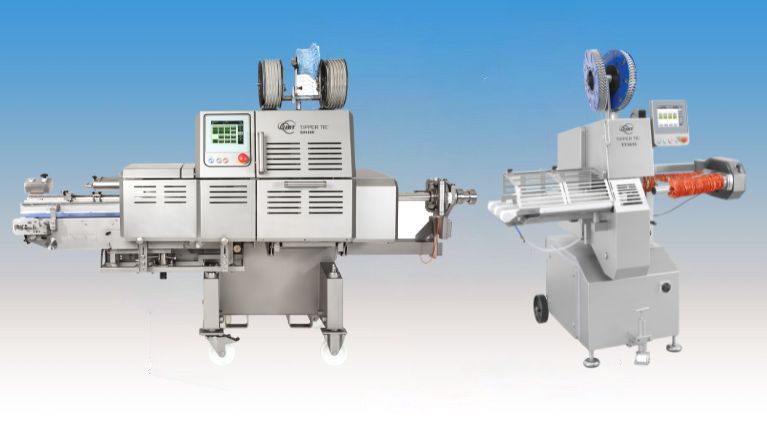

These vertical, table-mounted double clippers provide one-step closing on continuous netting and other rucked materials for a variety of foods and other packaged products.

Product Advantage

TIPPER TIE’s Double Clipper models apply tight closure on continuous netting and other rucked materials. These models provide one-step closing for netted products including smoked hams, turkeys, whole birds, poultry breasts, plants, and other packaged products. Stainless steel construction makes them food safe.

Double Clippers can be used to make handles on netted meat products, adding convenience to your packaging for retail customers.

These vertical, table mounted clippers are easy to use, clean, and maintain. Each model employs a powerful knife that cuts plastic, copolymer, cotton, and elastic netting.

TIPPER TIE clips are strong enough to hold securely, even through the smoking cycle in meat processing. A wide range of clip sizes are available, from 100T series to Z300 series clips. Double Clippers accommodate stick clips or spool clips for longer use between clip reloads.

Most Double Clipper models are throat-actuated and use spooled clips. Stick clips are optional on some models. The SD187 and SZ3215 series are both gate actuated, and Model SD187 uses stick clips.

Double Clipper Models

All Double Clippers feature stainless steel construction and meet AMI’s sanitary design standards for food grade operation.

Equipped with double sided dies and no cylinder springs, TIPPER TIE Double Clippers guarantee long machine life and durable performance. All models are available for left hand or right-handed operation.

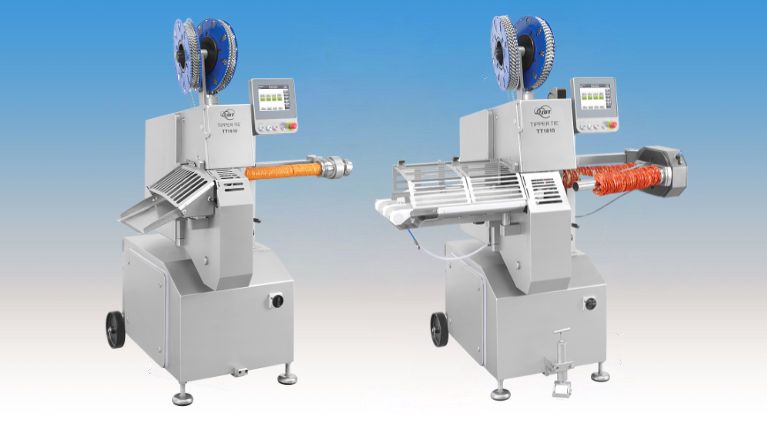

Hot Knife Models

Hot knife models cut netting flake-free, for a sanitary and appealing finish, especially on meat products. Adjustable crimping allows operators to easily fine tune clipping for different materials.

Hot Knife models plug into standard 110 VAC, 50/60 Hz connections, producing 100 watts of power. Heaters are regulated with a built-in temperature controller. Hot Knife models are available in both left hand and right-handed configurations.

Auto-Tagger

In addition to manual tag feed, many Double Clippers can be equipped with an auto-tagger.

The optional auto-tagger swiftly applies a tag in place, where it will be securely attached to the product in the same action that applies the clip. Tagging products assures clear, inexpensive branding identification for retail customers.

Premium Quality Clips

High-quality clips are essential to a successful clip closure. TIPPER TIE clips are manufactured from a special aluminum alloy and are held to exacting specifications that exceed those from the general wire industry. The dimensions of all TIPPER TIE clips are kept within very tight tolerances, ensuring a perfect closure every time. Furthermore, clip leg ends are radiused and lubricated to ensure that both clip legs form simultaneously and uniformly as the clip gathers the packaging materials. The result is a clip that closes smoothly and securely every time.

Features & Benefits

- Stainless steel construction

- Make convenient handles on netted meat products

- Easy to use, clean, and maintain

- Powerful knife cuts plastic, co-polymers, cotton, and elastic netting

- Strong TIPPER TIE clips hold securely even through smoking cycle in meat processing

- Throat-actuated and use spooled clips for longer use between reloads

- Wide range of clip sizes available

- JBT TIPPER TIE PRoCARE® available

Details

- Applications – hams, whole birds, sausage, deli meats, fresh ground meats, netted meats and poultry, non-meat protein, raw/frozen/refrigerated pet food, cheese blocks, netted cheese, nut paste/butter, netted produce, and absorbents

- Double-sided dies and no cylinder springs ensure long machine life durable performance

Options & Models

- Stick clips optional on some models

- Models SD187 and SZ3215 gate actuated

- Model SD187 uses stick clips

- Right hand or left-handed configurations

- Hot knife models cut netting flake-free for sanitary and appealing finish, and adjustable crimping enables fine tuned clipping for different materials

- Auto-tagger for branding identification