Full spectrum of innovative automated and semi-automated clip packaging machines plus closure, hanging, and labeling materials

Whether you’re producing the juiciest summer sausages, tastiest cheese, or the most savory stews, you need a way to wrap and seal your goods. With the broad and robust selection of TIPPER TIE machines, it couldn’t be easier.

In true JBT fashion, though, your TIPPER TIE system doesn’t just make clipping and packaging seem like simple work. It streamlines your whole operation — which leads to significant cost savings, production efficiencies, and more.

Through continuous improvements to the TIPPER TIE clipper machine technology, factory design and consultation, and customer service — JBT’s developed the best solutions over time. We’ve collaborated with customers and capitalized on every available advancement. Please view our Sales Territory Map to find your TIPPER TIE account manager or go to Contact Us.

TIPPER TIE Products Make Clipping & Packaging a Cinch

When it comes to clip packaging solutions, TIPPER TIE is unmatched in quality, capability, or innovation. Take a look and see for yourself….

Table Clippers

Available in several configurations and styles to meet your needs, these cost-effective closure machines are for products in casings, netting, or bags.

Get details

Semi-Automatic Clippers

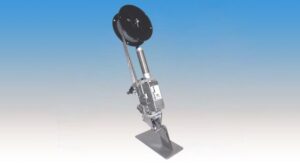

Boasting ergonomic design, flexibility, reliability, and more, these machines require some manual labor to complete the clipping process.

Get details

Automatic Clippers

Our extensive line of automated clipping solutions are the gold standard for high performance, consistency, precision, and labor savings.

Get details

Automated Hanging Systems

Boasting ergonomic design, flexibility, reliability, and more, these machines require some manual labor to complete the clipping process.

Get details

Net & Clip Systems

Offering maximum slicing yield, this equipment is ideal for whole muscle meats packaged in netting, like spiral-sliced or bone-in hams and whole turkeys.

Get details

Bag & Clip Systems

Securely close bagged whole poultry products, meats, and cheeses — for visual appeal and max shelf-life — with this line of bagging solutions.

Get details

Consumables

These clips, loops, strings and cords, and label systems — designed for and the perfect complement to our clipping machines — provide unparalleled performance.

Get details

Case Studies

Greater slicing yield. Labor savings. Increased throughput. See what some of our customers have to say about their TIPPER TIE solutions.

Get details

Parts Kits

TIPPER TIE is making it easier for you to get all the required parts for many major scheduled service procedures with all-inclusive parts kits.

Get detailsTIPPER TIE has a very long legacy in a range of industries and application, such as:

- Fruits and nuts

- Soups and sauces

- Food ingredients

- Non-food products

Smart Engineering for Better Business

Anything that improves, facilitates, or simplifies your production is likely a good thing. This ideology is at the core of JBT’s design/build efforts.

You’ll see this in the purposefully and intelligently engineered-in functionality of our systems. More than just bells and whistles, these design features translate into real productivity and financial gains for your business. Here are just a few examples:

- Construction that leverages industry leading processes and materials

- A machine — or more! — for every task

- Compatibility with other processing machinery

- Customizability and configurability to your requirements

- Requires less time to get up and running

- Minimal training needed to operate

- Reduces opportunities for human error

- More reliable machines

- Easier and less maintenance

- Fewer and less severe operational issues

- Longer service life and higher resale value

Even better, JBT’s advanced solutions make hitting your operational targets — like product quality, efficiency, downtime KPIs — easier.

Features & Benefits

All the features you could want or need are bundled into JBT’s clipping and packaging machinery. With capabilities like these, food production is consistently as fast, accurate, and safe as possible.

- Uptime — Intelligent design and robust construction result in reliable high performance

- Savings — Predictability, efficiency, and quality of systems slashes lifetime ownership costs and operational costs

- Sanitary — Hygienic design and installation for enhanced clean-ability

- Adaptability — Able to process a variety of products

- Options — Variety of models, options, and configurations available to create an ideal set-up

- Innovation — Extensive testing capabilities to help facilitate product development

- Support — Global support staff to help as needed

If you have questions about these features — or how they benefit your operations — contact us today.

Total Solutions for Your Food Processing Needs

JBT’s complete portfolio of high-quality products and services can take on the many and diverse tasks and challenges involved in food processing. On top of superb closure machines, we offer all manner of systems for food production, sterilization, packaging, storage, conveyance, and more. Plus, we have the essential detergents, lubricants, replacement parts, and upgrade kits to keep your set-up in lock-step with your operational needs.

With JBT you get so many advantages: flexibility, adaptability, expertise, variety, quality, and more. Plus, we make the process of assembling your production line straightforward and virtually hassle-free.

Your Production Line — Equipped End-To-End

Whether you want to swap one new machine into your assembly line or build out a whole new factory, JBT has you covered. We can supply you with the right equipment to get the job done properly. With the quality, quantity, and variety of processing equipment we offer, you’re able to:

- Conveniently source solutions from a single provider

- Customize your production line to your specifications

- Mix and match equipment brands to get exactly what you need

- Easily replace individual components of your current production line

- Respond to changes with greater agility

- Scale your operations more seamlessly

JBT, Your Trusted FoodTech Partner

With JBT meeting your end-to-end food production needs, your search for a solutions provider is over.

Customer Focus, The Path to Success

We want your business to flourish — when you do well, we do well. To this end, JBT strives to establish a productive long-term relationship with you. In this way, we can serve you more thoughtfully and holistically today and all the tomorrows that lay ahead.

Innovation & Expertise Hubs

One stand-out perk of working with JBT — our Research & Technology Centers. Far from being just a test kitchen or lab, you can try out machines, explore production line configurations, perfect your recipes and techniques, and access technical expertise and data at these unique facilities.

Connect with JBT Specialists

JBT’s been dominating the foodtech industry since the late 1800s. You’re encouraged to take advantage of our massive store of knowledge and experience. We provide this premium level of support because we know running a food processing business can be complex — and a bit of help along the way can make all the difference. So, feel free to contact JBT’s dedicated and skilled team for help.

CONTACT US

We’re here to help every step of the way.