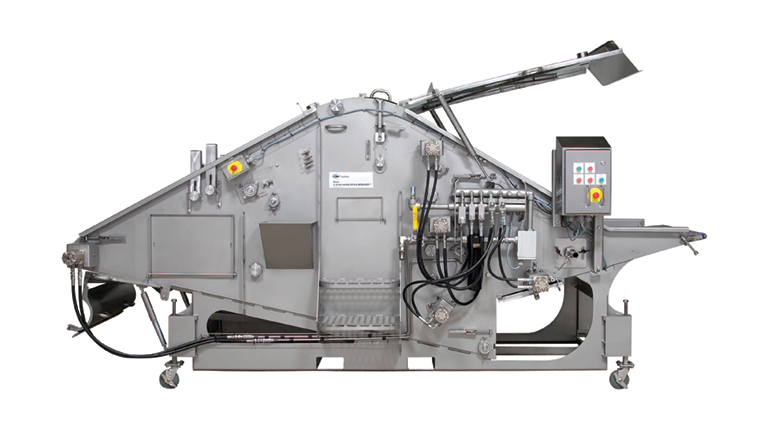

High-speed, reliable, and simple-to-operate seaming technology for liquid applications

At JBT, we’re all about combining innovative designs with proven technologies to make food processing simpler, faster, and better. When it comes to can closing, you shouldn’t have to choose between speed and quality. We offer a wide range of versatile seamers that are suitable for liquid applications with speeds from 100 to 1,500 cans per minute (cpm).

With over 750 machines sold worldwide, the X-52 grease-lubricated seamer is one of the canning industry’s most popular seamers. The X-59 oil-lubricated seamer outperforms the competition in terms of speed while also setting new standards for consistency, hygiene, ease of operation, safety, and efficiency.

JBT’s can closers are designed to provide you with superior results while minimizing the overall cost of ownership. With limited maintenance requirements and strategic automation, you can increase production speeds and end-product consistency while saving valuable time and money.

Features & Benefits

Consistency, efficiency, and simplicity come together to deliver the most cost-effective and results-driven can closing solutions in the FoodTech industry. Designed to accommodate a wide variety of applications, the X-52 and X-59 are designed for seaming cylindrical metal cans for any type of food, dairy, or beverage product with speed and precision. Primary advantages include:

- Superior reliability – With all gearing contained within one oil bath at the top housing of the machine, JBT’s X-59 can closer offers a unique combination of extreme reliability, low maintenance requirements, durability, and ease of use.

- Sanitary design – The closer’s stainless steel design and easy-to-access product contact areas make it ideal for applications that necessitate high standards of hygiene or involve corrosive products. There is also an optional wash-in-place (WIP) system available.

- Improved user safety – The machine is equipped with full-length stainless steel guards that have polycarbonate windows and optional LED lighting, in addition to wide interlocked doors to accommodate easy accessibility to the seaming area for maintenance, adjustments, and change-over. The fully-enclosed design maximizes operator safety at every level.

- Consistent seam quality – Power-driven seaming spindles and lifter plates produce high-quality double seams every time, even on the most lightweight cans.

- Automatic lubrication – The X-59’s full automatic oil flow system lubricates each and every machine part, including seaming heads, lifter tables, and seaming rolls, without the need for downtime. The system also features a high-performance oil recovery filtration system.

- Maximum efficiency – The X-52 series covers the speed range from 100 to 600 cpm, while the X-59 series covers the speed range from 300 to 1,500 cpm, Stainless steel, spring-loaded knock-out pads and reduced diameter lifter tables with low-lift cams to minimize spillage are combined with a highly efficient air-removal system to reduce waste and increase processing speeds.

Customizability Meets Low-Maintenance Design

JBT’s line of automatic can seamers marry reliable quality with fast-paced operation. With adjustable speeds from 100-1,500 cmp depending on your machine preferences, you have the power to control throughput to best serve your particular production goals. But ultra-efficient performance doesn’t have to come with additional costs. Our can closers offer easy maintenance with ergonomic designs that prioritize user experience and efficiency. Stainless steel surfaces, electrically interlocked doors for ease of maintenance, and optional wash-in-place technology significantly reduce downtime and increase overall system efficiency.

FAQs

Does JBT offer compatible fillers?

Yes. Both the X-52 and X-59 can seamer sealing machines are perfectly synchronized (mechanically or electronically) with JBT’s comprehensive range of fillers, empowering you to achieve a high-performance filler-closure group that will seamlessly integrate with your existing processes. JBT aims to consistently deliver equipment and other solutions that provide processors with the highest level of flexibility in terms of production line setups and approaches, and our can closers are no exception.

How do JBT’s can closers reduce waste?

Our can closers not only increase yield with high-speed production capabilities, but they’re also designed to improve the accuracy and reliability of each individual end product. With automatic lubrication and state-of-the-art seaming technology, you’ll see uniform and quality output. Our closers are also fitted with stainless steel, spring-loaded knock-out-pads and reduced diameter lifter tables that decrease the chance of product spillage. This results in far fewer wasted products and more accurate output estimates.

What is required to maintain X-52 and X-59 can closers?

Our can closing solutions are designed to significantly reduce the need for downtime, maintenance, and replacement parts. Both the X-52 and X-59 closers are designed to accommodate easy access to all major assemblies, which minimizes downtime and related product losses. When maintenance is required, you can rely on JBT’s expert support specialists to provide quick and helpful answers to your questions and the highest quality of support and service upon request.

JBT – Your Faithful Partner in FoodTech

For over a hundred years, JBT has been committed to the same goal – harnessing the power of technological innovation to empower food processors to reach their goals with better, simpler solutions. With our tenacious approach to research and development, our focus on facing challenges head on, and our emphasis on collaboration, we’ve slowly but surely built a reputation as a global industry leader in food-processing technology.

We know that our success depends on your success. That’s why we take the time to truly and thoroughly understand the challenges and obstacles you face in your industry so we can deliver targeted solutions to specific issues and demands in your particular markets. We’re in your corner, and together there’s nothing we can’t accomplish.

High-tech Research Facilities

At JBT, we value transparency and collaborative efforts. As our partner, you’ll get full access to our cutting-edge Research and Technology centers. With more than a dozen facilities worldwide, you’ll have the opportunity to work directly with our specialists, refine your recipes and production line setups, test new equipment, and more.

A Dedicated Customer Service Team

Our journey as a FoodTech trailblazer has taught us a lot about food production and industry needs. But our experience has also given us the chance to learn just how important it is to maintain beneficial and highly effective business relationships. We know that prioritizing customer experience and providing reliable, first-rate support is key to your success, and to ours.

JBT’s customer support team is composed of FoodTech experts who are available day and night to offer you direct assistance regarding your operation, as well as valuable insight into a variety of industry-specific market trends.

We’re here to help you meet your goals and reach your full potential. Contact us anytime to learn more about our offerings and become a JBT partner.