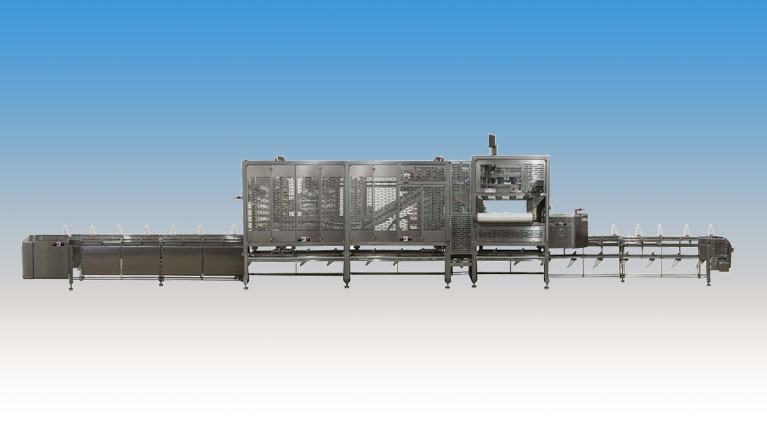

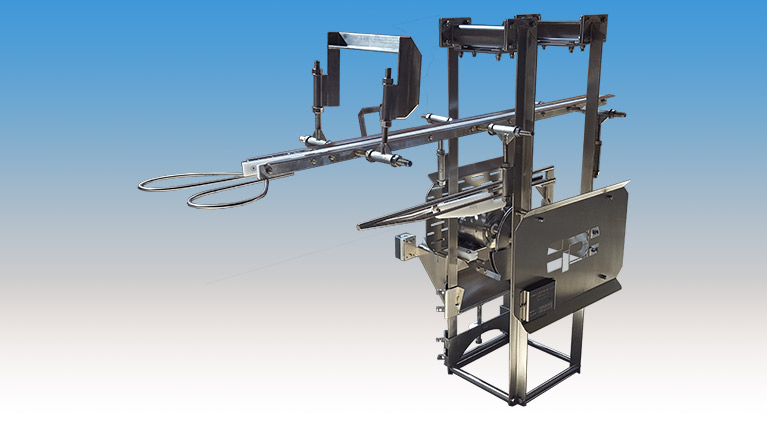

ILBD-2T In-Line Breast Deboner for Turkey

Our In-Line Breast Deboner for Turkey is an all-new approach to automating breast deboning that significantly reduces staffing, and provides consistent, high-yield results that meet or exceed cone line whole-muscle yields. With a small footprint compared to the cone line it replaces, the ILBD-1T is an efficient, labor-saving solution that solves multiple processing problems.

Features & Benefits

- Automates breast deboning for turkey

- Reduce staffing and training needs

- Yields designed to meet or exceed cone line whole muscle yield

- Staff positions are low-skill

- Impressive ROI and long-term savings

- No incoming product temperature requirement

- Significant staffing reduction saves on labor and training

- Lower capital investment compared to other automation

Details

- Water requirements: 1-3 gpm, room temperature (not hot), 40-100 psi

- Air requirements: 80 psi

- Electrical requirements: Standard is 480 VAC, 3 phase, 60 Hz, 40 amps

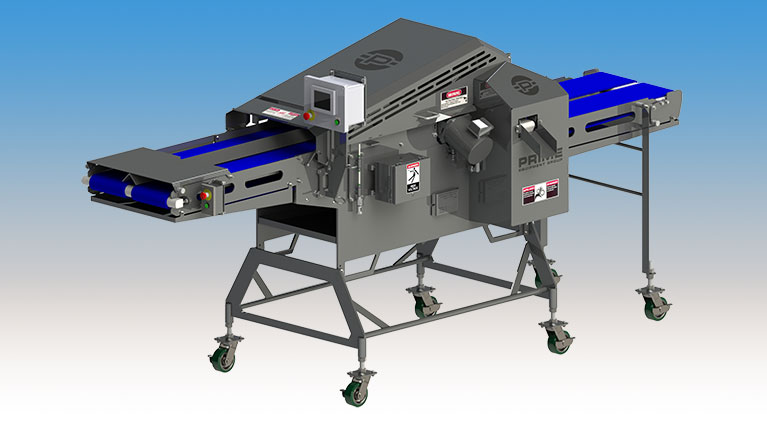

CFS-TSK-1 Turkey Thigh Skinner-Deboner

Our Prime CFS-TSK-1 Turkey Thigh Skinner Deboner effectively removes meat and skin from turkey thighs utilizing JBT Prime’s patented bladeless skinner and high-pressure water jets. CFS-Series units produce an open meat fillet ready for trimming, and our method of water jet deboning has been operating successfully across the U.S. turkey industry for more than two decades.

Features & Benefits

- Water jet provides precise separation of meat from bone

- Highest yield of any method

- Proven technology in use industry-wide

- Simple design is reliable in operation

- Prime skinner and water jet deboner maximize yield while minimizing bone fragmentation

- Requires only a single operator per machine, which lowers labor costs and raises your bottom line

Details

- Electrical Requirements: (1) 2 hp, (1) 0.18 hp; 480V, 3 ph, 60 Hz, 80 amps

- Water Requirements: (1) 2 connections; 10.0 GPM (52.99 LPM) ; 40 PSI min.

- Air Requirements: 100 PSI minimum; Dry, for maintaining cylinder pressure; does not consume air

- Pump Requirements: (1) 40 hp; 480V, 60 Hz

- Net Weight: Base Unit: 1,500 lbs. (680 kg) Hammelmann Pump Stack: 600 lbs. (272 kg)

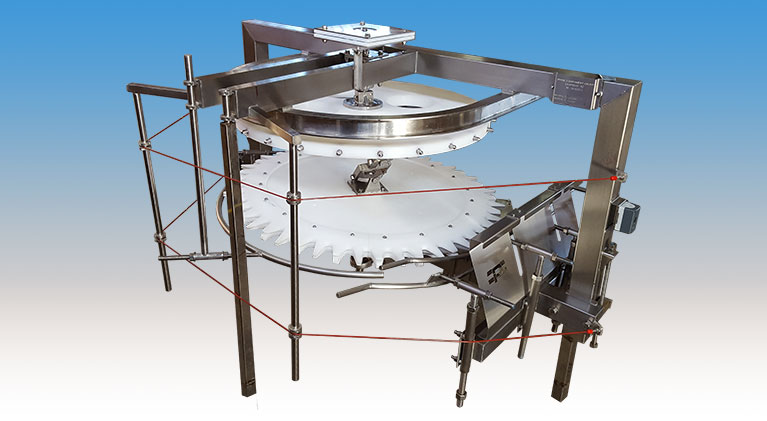

CFS-LT3-T Thigh Deboner for Turkey

Available for turkey, Prime Equipment Groups thigh deboning machines utilize an innovative water jet to remove meat from bone. They require only one operator for effective operation. The turkey models (CFS-LT3-T and CFS-DR-W) remove meat from turkey thighs, drumettes, and two-joint wings.

Features & Benefits

- Water jet provides precise separation of meat from bone

- Proven technology in use industry-wide

- Fillet suitable for further processing; not for tray pack

- Water jet maximizes yield with consistent skinning action that wont chip bones

- Simple, proven design uses a single machine for multiple operations

Details

- Electrical Requirements: (1) 2 hp, (1) 0.18 hp; 480V, 3 ph, 60 Hz,60 amps

- Water Requirements: (1) 2 connection: 7.0 GPM (26.49 LPM); 40 PSI minimum

- Air Requirements: 100 PSI minimum; Dry Maintained

- Pump Requirements: (1) 20 hp; 480V, 60 Hz, 30 amps

- Net Weight: Base Unit: 1,500 lbs. (680 kg)

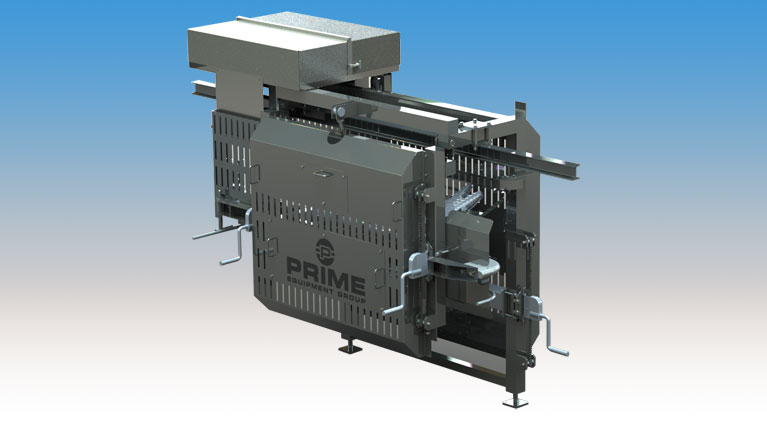

KSR-1T Keel Strip Remover for Turkey

Our KSR-1T Turkey Keel Strip Remover, is designed to remove the keel strip from a full turkey breast fillet, cutting the fillet into three pieces: two breast lobes and a center keel strip. Its high degree of accuracy and consistency improves yields over hand processing, and requires only a single loader in a low-stress capacity that does not require extensive trim training.

Features & Benefits

- Efficient, effective, consistent keel strip removal

- Positioned downline from whole breast removal

- Effective at 22-25 whole breasts per minute

- Improves yield vs. manual keel strip removal

- Reduces labor – only a single loader needed

- Simple loading operation eliminates training

Details

- Electrical Requirements:

- (1) 2 hpmotor; 480V, 3, 60 Hz, 15 amp

- (2) 1/2 hp motors; 480V, 3, 60 Hz, 15 amp

- Water Requirements: 1/4 NPT connection; 2.0 gpm, 40 psi minimum, room temperature

- Production Rate: 22-25 Hen or Tom Butterfly Breasts/min

KPS Keel Cleaning System

Our Prime Chicken Keel Cleaning System efficiently separates meat from cut chicken keels, producing a clean keel product that is ready for shipment or processing. Keels are pumped to a specially designed picker-scalder, where heated water and fingers separate the meat. Keels flow to processing, while the process water is screened to remove solids and re-circulated back to the picker-scalder for water and BTU savings.

Features & Benefits

- Separates meat from cut keel

- Prepares clean keels for processing

- Screen/tank system separates meat from process water and re-heats water for re-use

- Complete system for keel cleaning offers high through-put and ease of use

- Water separation tank is designed to conserve water and heat for low cost of use

Details

- Electrical Requirements:

- KPS-1: Drive- (1) 15 hp, 480V, 3 ph, 60 Hz

- Spray bar pump- (2) 7.5 hp

- LPS-112: Drive – (1) 1.3 hp, 480V, 3 ph, 60hz

- Spray bar pump – (1) 20 hp

- Steam Unit Requirements: Electrical: 20V, 1 ph, 10 amps

- Air Requirements: 100 psi 1/4-inch NPT connection

- Water Requirements: 350 gallons to fill holding tank; additional make-up water during operation

- Production capacity: 25 pounds of keel per minute

- Weight:

- KPS: 1,800 lbs empty; 2,400 lbs full

- PPS: 1,800 lbs empty; 2,200 lbs full

Cone Deboning Line

Semi-Automated Cone Line Deboning with the Prime Smart Cone LineOur Prime Smart Cone Line Deboning System provides industry-leading yields and labor efficiencies by automating processes along the line while harvesting wings, breasts, tenders and keel cartilage from the front half of the bird. The Prime Smart Cone Line allows for faster line speeds with less labor while improving yields. Prime machines fit adjacent the cone line for optimal ergonomics, while eliminating dangerous and strenuous tasks on the line. The industry’s top producing plants all use the Prime Smart Cone Line.

Features & Benefits

- Offers the industry’s best yield–the top-ranking plants in the U.S. use this system.

- Low capital costs and savings that pay back every day

- Strategic automation eliminates strenuous jobs

- Workers used where skills offer best yield

- Reduces staffing, typically from 17 to 13

- Allows for faster line speeds (40 BPM vs. 34 BPM)

- Machine placement allows optimal ergonomics

- Compact footprint offers layout flexibility

- Reduces labor significantly

- Allows for faster processing line speeds

- Safe to operate & easy to maintain

- Engineered specifically to suit your production requirements

BSC-1 Back Skin Cutter

Our Prime BSC-1 Back Skin Cutter is designed to work with the HM-Series Halver to fine-tune the location of the skin cut between the front and back halves. This allows for extra yield to remain with either half. Additionally, the BSC-1 enables the front half to be dropped at a location downline from the halver for ease of product flow.

Features & Benefits

- Located down line from halver

- Allows fine-tune of skin cut to increase yields

- Can drop front half away from halver

- Maximizes yield as desired by leaving extra skin on front half or back half

- Eliminates wing damage and wing pinch points

Details

- Electrical Requirements: (1) 1 hp motor, 480 volts

- Water for blade: 1/4 NPT, plant pressure

- Weight: 400 lbs (181 kg)

- Production Rate: Variable with line

HM-2 Chicken Halving Machine

Our Prime HM-2 Chicken Halving Machine automatically and effectively separates the front half from the saddle. Operating at speeds exceeding 180 BPM, the HM-2 can be adjusted to remove more rib bones or saddle to maximize leg quarter yield. The Halving Machine can be adjusted to completely cut front halves from the saddle or leave the front half hanging by the back skin, to be removed by the back skin cutter to maximize skin and fat yield.

Features & Benefits

- Line-driven solution for halving designed to allow for production flexibility

- Easy adjustment for changes in product requirements

- Adaptable to, and can improve yields on various overhead lines

- Efficient: requires no additional power or operator

- Versatile: adjustable for different processing options

- Backed by the FoodCraft re-engineered by Prime service network

Details

- Electrical Requirements: N/A – Line driven

- Hydraulic Requirements: N/A – Line driven

- Net Weight: 800 lbs. (363 kg)

- Gross Weight: 950 lbs. (431 kg)

- Length: 510 (1.78m)

- Width: 74 (2.24m)

- Height: 41 (1.24m)

- Production Rate: Up to 180 BPM