Conserve water, reduce energy costs, and improve sustainability with JBT’s water reuse system

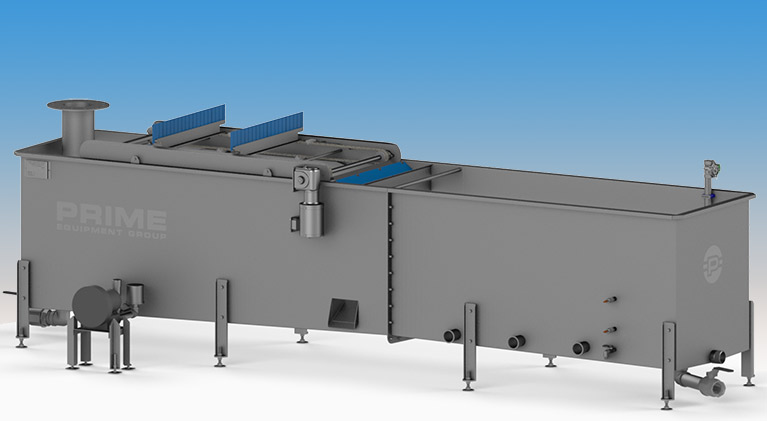

It’s more important than ever before to balance your sustainability efforts with the cost of capital and labor. The JBT Prime Water Reuse System is designed to dramatically reduce your water and energy consumption with minimal initial investments of time and money. It’s a customizable, recirculating water sanitation system that’s built to integrate with the rest of your equipment and processes.

Our exceptional engineers at JBT Prime developed the system to automate and simplify the water sanitation process, help reduce chemical use, and lower the cost of ownership by minimizing the need for piping, utilities, and labor. It’s user-friendly and convenient, built to save you money and labor while enabling you to do the right thing by recycling and reusing water. It’s also tough and durable and requires minimal maintenance and employee training.

Features & Benefits

At JBT, we’re committed to developing advanced solutions that remove the need for sacrifice and compromise. You don’t have to choose between efficiency, cost savings, and automation. With JBT’s Prime Water Reuse System, you get all three in a completely turnkey, customizable system.

Here are just a few of the features you’ll gain:

- Easy to operate – Our Prime water reuse system was designed to be automated and intuitive to operate; it also requires minimal maintenance over time.

- Integratable – The system was developed with the specific purpose of minimizing disruptions and integrating seamlessly into your existing processes.

- Sustainable – Save water while doing your part to create a more environmentally responsible future in your industry.

- Compliant – We perfected the system with rigorous development and testing, and then worked with the USDA to create the rules that allow water to be reused in poultry plants; cutting your water consumption can eliminate municipal fines for excess water usage.

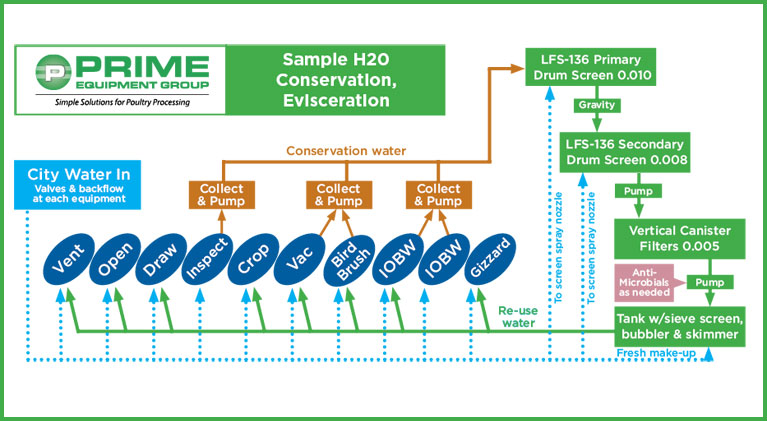

- Efficient and cost-effective – Companies that employ our Prime water screening and reuse systems can often reuse 90% or more of the water collected at their facilities, reducing overall water consumption (and associated energy costs) by as much as 20%, depending on the application.

- Superior performance – Our Prime water screening and reuse systems can remove solid particles greater than 0.008 inches (200 microns) in size, in volumes ranging from 50-70 GPM.

Unmatched Flexibility & Convenience

The JBT Prime water reuse engineering team has more than 20 years of experience designing and developing simple, effective solutions.

Our engineers carefully designed the water reuse system with diverse customer needs in mind. A standard system includes a first-stage rotating stainless-steel wedge-wire drum screen for larger particles, which is followed by second-stage vertical filters for finer particles. Our team can also engineer a complete control package, using VFDs, flow meters, and sensors to provide a comprehensive, self-balancing system that requires minimal manual oversight. Our JBT Prime team can customize our systems to meet your plant’s needs.

Common process water-reuse sources include:

- Bird washer (iobw) chiller overflow

- Rinse cabinets bird scalder

- Bird scrubber raw picker scalder

- Hock scrubbers and more

JBT – Your Partner in FoodTech

Back in the 1880s, when JBT got its start in the FoodTech industry, we made it our mission to continuously strive for better. We never settle for “good enough.” When we reach one goal, we set new ones and continue to push the limits of what’s possible in Food Tech.

We understand the importance of strong, long-lasting partnerships in the food-processing industry. We don’t create standard solutions. We take the time necessary to understand every client’s goals, needs, and challenges, and then develop and deliver specific, targeted solutions.

When you work with us, you’ve got a robust industry leader in your corner. Together, we can pave new roads in the FoodTech industry and carve out your unique competitive advantage.

Advanced Technologies for Diverse Markets

You don’t need us to tell you about the demands and challenges in your industry. You’re the expert in your processes and markets. Our goal is to empower you to meet those demands head-on, with the highest quality machinery and expertise in the world. Over the years, we’ve developed long-lasting partnerships with unique clients in diverse industries around the globe. These industries include:

JBT’s Collaborative Research & Technology Centers

In FoodTech, innovation is more than a goal – it’s a necessity. Your competitors won’t stop pushing the boundaries, so you can’t either. Throughout our long history, JBT has continuously strived for better and better, developing new cutting-edge technologies every year.

When you partner with us, you’ll have access to our Research and Technology Centers, where you’ll get to work alongside the world’s top industry experts as you develop and test targeted solutions to enable you to streamline your operations and improve your bottom line.

At our state-of-the-art R&D centers, you can:

- Test product safety, quality, and compliance

- Experiment with top-of-the-line equipment and production-line setups

- Fine-tune and perfect your recipes and processes

- Analyze industry data and work alongside trusted experts

High-Tech Solutions & Expertise At Your Fingertips

At JBT, we do more than just manufacture equipment. We’re your partner, supporter, and guide, dedicated to helping you reach your goals. Our expert support team is available around the clock to help you determine how to optimize your production lines, streamline your operations, and face the toughest challenges in your industry.

Contact us today to learn more about our robust offerings and superior solutions.