Maximize efficiency and improve end-product quality with JBT’s state-of-the-art poultry oil gland remover.

Food production – especially poultry, meat, and seafood processing – represents one of the toughest and most competitive industries in the world. As technological advancement continues to transform the way the economy operates, producers who embrace automation are gaining an invaluable competitive advantage.

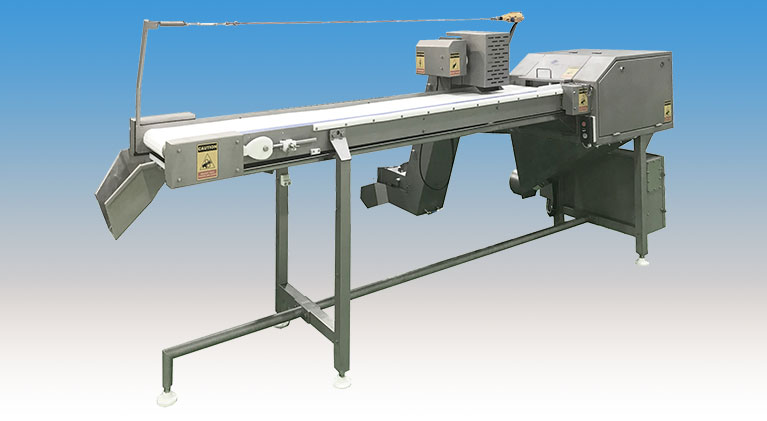

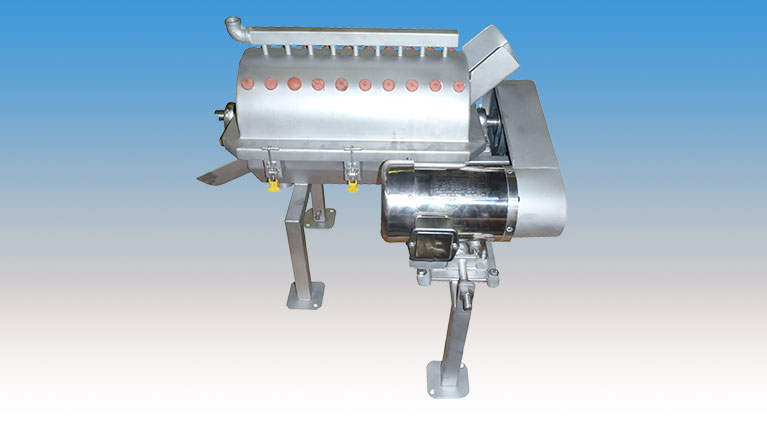

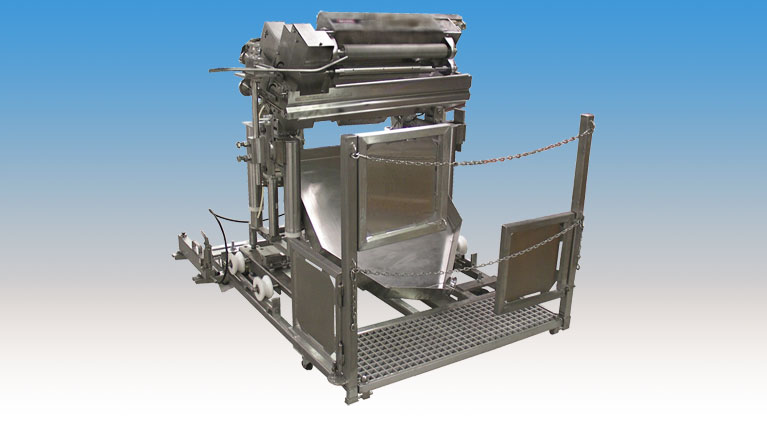

The OGR-1 Turkey Oil Gland Remover from JBT is built to seamlessly integrate into your existing production line and maximize efficiency. It’s designed to increase yield, improve consistency and quality, and minimize labor requirements to save you valuable time and money. Utilizing a set of inward-rotating steel roller shafts, the machine is built to automatically remove the oil gland from male and female turkey tails. It includes a wide array of adjustment features to accommodate nearly any bird size, as well as an optional tail-cutting module that saves labor.

Harness the power of automation and capture your competitive advantage with JBT’s cost-effective, high-tech solutions.

Features & Benefits

The OGR-1 Turkey Oil Gland Remover is a high-tech, turnkey solution that offers processors greater flexibility while increasing efficiency and eliminating unnecessary costs. With a straightforward, innovative design, you’ll have the tools you need to optimize your existing system and bring your production line into the future.

- Improved Consistency – Automated machine cutting offers significantly greater consistency compared to manual cutting, resulting in a more hygienic and desirable end-product.

- Optimal Spacing – Overhead line indexer ensures that birds are metered and spaced properly to maintain efficiency and streamline production.

- Flexibility – The OGR-1 is highly customizable, allowing you to adjust configurations to process hens and toms of all sizes and address your specific concerns while maximizing your processing potential.

- Reduced labor costs – Cutting-edge automation eliminates the need for unnecessary labor when removing oil glands and limits your manual labor requirements, simplifying your line and saving you money.

- Increased yield – With an efficient design and improved processing speed, you’ll see significant expansion of your throughput capabilities and increase your overall yield.

- Proven design – High-tech automation technology is combined with tried-and-true methods to give you time-tested, reliably uniform results.

Efficiency Meets Quality

JBT is committed to innovation, but we don’t believe in standardized, one-size-fits all solutions. We know that producers have specific needs, challenges, and goals they face in their unique production lines and markets. That’s why we build our FoodTech equipment to be highly customizable.

Like with other JBT machines, the OGR-1 Turkey Oil Gland Remover is designed to automate processing across a range of applications, without sacrificing speed, yield, or quality. The oil gland remover is adjustable for hens and toms, and the optional tail-cutting module gives you maximum flexibility without the risk and inconsistency that can come with labor-intensive processing.

FAQs

What are the OGR-1’s production rates?

With its automation-focused design and customizable options, the OGR-1 Turkey Oil Gland Remover has the capability to significantly improve production rates. Depending on your current needs and goals, you can configure your machine to achieve production rates of up to 45 toms and 55 hens per minute. A consistent end product also reduces wasted output, providing you with a reliable yield and ultimately improving overall efficiency.

Can the OGR-1 be used in conjunction with non-JBT processing equipment?

Yes. While we stand by the quality and value embedded in every piece of machinery we design and produce, we understand that processors need solutions that can integrate with their existing production lines and applications. We’re committed to providing integrative, flexible solutions – in the Poultry, Meat, and Seafood spaces and beyond – that can be incorporated into your current processing setups and configurations, and the OGR-1 Turkey Oil Gland Remover is no exception. Contact us for more information.

What are the OGR-1’s labor requirements?

JBT is dedicated to providing user-friendly, turnkey solutions to our partners in a variety of industries. That’s why the OGR-1 Turkey Oil Gland Remover requires no extensive training to operate effectively. In fact, its straightforward yet high-tech design eliminates the need for a designated operator, and can reduce your labor requirements by one to two workers per shift.

JBT – State-of-the-Art Equipment & Unmatched Support

JBT got its start in the FoodTech industry back in the late 1800s, and while a lot has changed since those early days, a lot has stayed the same. As we’ve continued to push the boundaries of innovation and technological progress, we’ve never lost sight of our core values. We believe that integrity, loyalty, and collaboration are foundational components of success in business.

We don’t just design, produce, and maintain the highest quality food-processing equipment in the world. We also build long-term partnerships with our customers, working hard to understand their unique strategies, challenges, and goals so that we can offer targeted solutions and round-the-clock support that truly make a difference.

Innovative Global Research Centers

When you choose to work with JBT, you’ll gain coveted access to our Research and Technology Centers. With over a dozen facilities around the world, these hubs of innovation and collaboration bring industry experts and business leaders together to share ideas and explore possibilities. Join us and work side-by-side with our specialists as you test new machinery, hone your processes and recipes, and experiment with various configurations and setups.

The Best Support Team in the Industry

Our commitment to providing effective, personalized solutions to our customers extends beyond state-of-the-art equipment. JBT’s support team offers you direct communication with industry experts 24/7. Whether you need help with maintenance and repairs, are looking for insight into market trends, or have a question about one of our machines or services, you can rest assured that you have the most competent and responsive support team at your fingertips.

Contact us today to inquire about our offerings and ask any questions you may have.