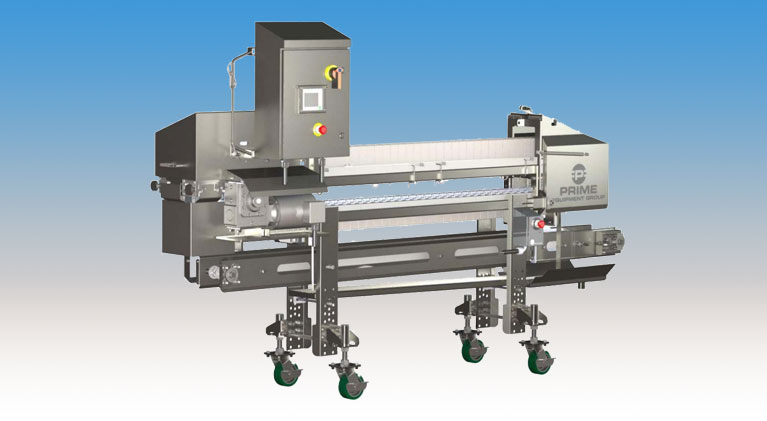

TMWS-1 Turkey Mid-Wing Splitter

Our Prime TMWS-1 Turkey Mid-Wing Splitter separates turkey mid-wings into two pieces at a rate up to 100 pieces per minute, with a well-guarded cutting area that improves operator safety. Up to four machine operators load two midwing pieces into each of the plastic product cavities. The TMWS-1 is the simplest and most consistent mid-wing cutting solution in the industry today.

Features & Benefits

- Cavity promotes precise wing positioning for consistent cuts

- Well-guarded cutting area improves operator safety

- Narrow frame maximizes ergonomics

- Consistent A-Grade mid-wing cuts

- Increased worker productivity and safety

- Flexible space for two-four associates depending on production needs

Details

- Electrical requirements: (1) 2 hp motor, 208-230/460V, 60 Hz

- Water requirements: 1 GPM, 40 PSI (min), 3/8” OD inlet

- Net Weight: Approx: 2,000 pounds

- Production rates: Up to 100 mid-wings/min; rate varies by number of operators

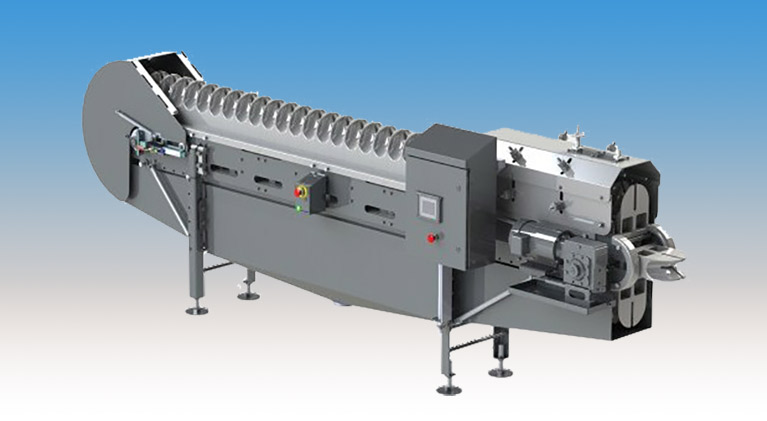

TWS-1 Turkey Wing Segmentor

Our Prime TWS-1 Turkey Wing Segmenter is an innovative and safe solution designed to separate whole turkey wings into two or three pieces. Designed for either online or offline applications, this machine uses no rotating blades and delivers unmatched cut quality compared to other methods. The TWS-1 features Delrin products cavities for accurate loading, with quick-disconnect capabilities for trouble-free sanitation.

Features & Benefits

- Improve worker safety with well-guarded cutting area vs. traditional methods

- Excellent cut consistency and quality

- Removable product cavities for sanitation

- Real-time safety alerts and troubleshooting guidance provided by pro-face touch screen

- Reduce labor costs associated with manual wing separation

- Consistent design produces more a-grade wing cuts

- Capable of operating at speeds of up to 100 wings per minute

- Removable cavities speed and improve sanitation

Details

- Electrical Requirements: (1) 2 hp motor; 480V, 3 ph, 60 Hz, 15 amps

- Water Requirements: (1) 3/8 poly connection; 1.0 GPM (3.78 LPM); 30-60 PSI

- Net Weight: 1,635 lbs. (742 kg) -as shown with (4) loading stations

- Production Rate: Turkey Wings, Tom: Up to 100 per min. Turkey Wings, Hen: Up to 100 per min.

CMWS-2 Chicken Mid-Wing Splitter

Our Prime CMWS-2 Chicken Mid-Wing Splitter separates chicken mid-wings into two pieces at a rate up to 300 pieces per minute, with a well-guarded cutting area that improves operator safety. One to six machine operators load two mid-wing pieces into each of the plastic product cavities. The CMWS-1 is the simplest and most consistent mid-wing cutting solution in the industry today.

Features & Benefits

- Cavity promotes precise wing positioning for consistent cuts

- Well-guarded cutting area improves operator safety

- Narrow frame maximizes ergonomics

- The CMWS-2 Produces a new consumer wing product

- Consistent a-grade mid-wing cuts

- Increased worker productivity and safety

- Modular approach allows working stations to be added or removed depending on production needs

Details

- Electrical Requirements: (1) 1 hp motor; 480V, 3 ph, 60 Hz, 10 amps

- Water Requirements: (1) 3/8 poly connection; 1.0 GPM (3.78 LPM); 40 PSI min.

- Net Weight: 2-station–600 lbs. (272 kg); additonal station (30 L) –250 lbs (113 kg)

- Production Rate: Up to 300 mid-wing pieces per minute, depending on machine length

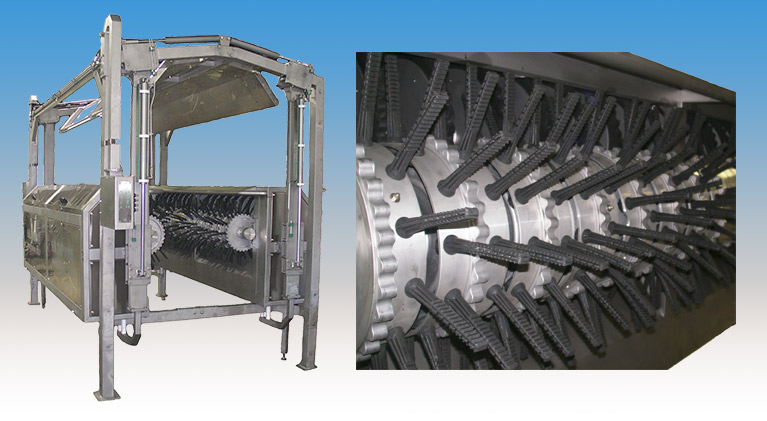

CWS-1 Chicken Wing Segmentor – Fixed Blade

Prime Equipment Group originated the wing segmenter category, making the first machines to eliminate inconsistent hand saws.The CWS-Series Segmenters are the market leaders, with more than 400 in operation worldwide. The CWS-Series leads the industry in:

Features & Benefits

- Improves worker safety by automating hand-saw cuts

- Produces consistent a-grade wing cuts

- Two options allow for different look to final products

- Improve safety vs. Operator on hand saw

- Consistent cuts produce higher percentage of a-grade wings

- Improve efficiency and labor utilization

Details

- Electrical Requirements: (1) 1 hp motor; 480V, 3 ph, 60 Hz, 10 amps CWS-RB: + 1/2 hp; 480V, 3ph, 60 Hz, 8 amps

- Water Specifications: (1) 3/8 poly connection; 1.0 GPM (3.78 LPM); 40 PSI min.

- Net Weight: 2-station (shown) 600 lbs. (272 kg) Additional station (30L): 250 lbs. (113 kg)

- Production Rate: Up to 200 whole wings per minute, dependent on machine length

Scalding

Defeathering

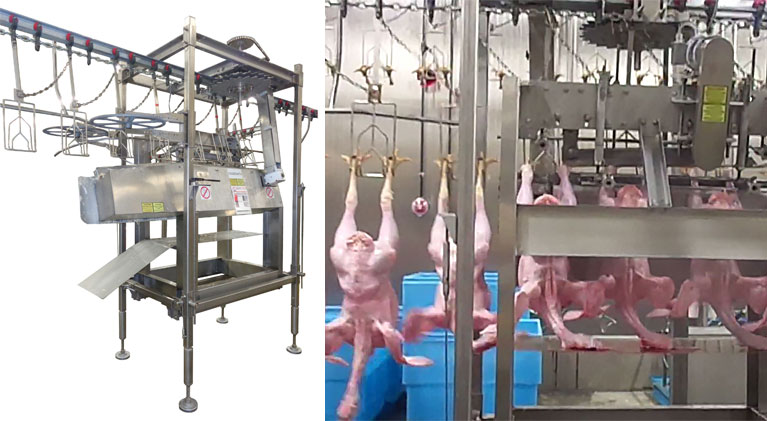

HAM-VI-B Hock Cutter

The HAM-VI-B Hock Cutter uses an oscillating blade to consistently and accurately cut hocks at up to 200 chickens per minute or 100 turkeys per minute. A positive-positioning chain places hock joints under the blade, and guides bend hocks to the proper angle for exact blade contact. Vertical adjustments are quick and easy to size to any bird, from chickens to turkeys.

Features & Benefits

- Proven, high-capacity, design

- Adjustable for any bird size

- Ideal with with re-hang systems

- Gear-driven transport system from overhead line

- Delivers precise, consistent cuts

- High-capacity design operates at up to 200 chickens per minute or 100 turkeys per minute

- Line-driven solution with a single motor offers long life and easy maintenance

Details

- Electrical Requirements: (1) 1hp 480V, 3 ph

- Air Requirements: (1) 3/4 connection

- Weight: 500 lbs

- Production Rate – Chicken: Up to 200 per minute

- Production Rate – Turkey: Up to 100 per minute

Options & Models

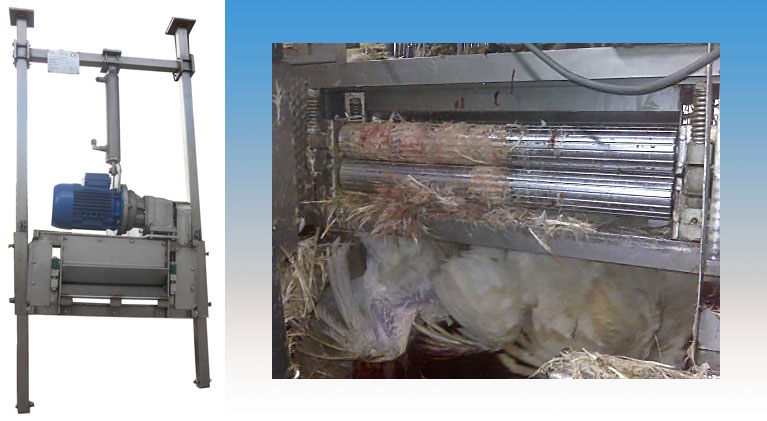

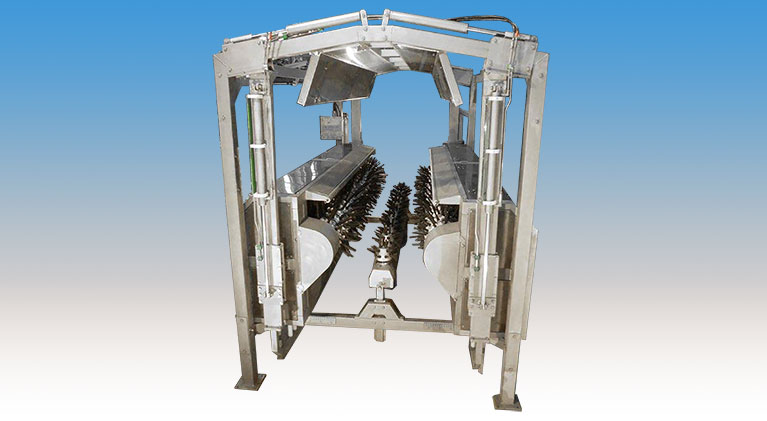

SC-Series Tail Quill Puller

The MSC-40 (chicken) and SC-40 (turkey) Quill Pullers are proven, reliable solutions for removing tail quill feathers from chicken and turkey. Fully adjustable for height and angle, the Quill Puller offers maximum flexibility for fine-tuning tail picking.

Features & Benefits

- Manual hydraulic height adjustment

- Roller tension adjusted with heavy-duty springs

- Simple, proven, durable design

- Can allow for lower scalding temperatures when placed before the scalder

- Low-maintenance design

- Low parts-replacement costs

Details

- MSC-40 (chicken) motor: 1.5 hp

- SC-40 (turkey) motor: 4 hp

- Weight: 200 lbs.

- Production rate: Variable with line speed