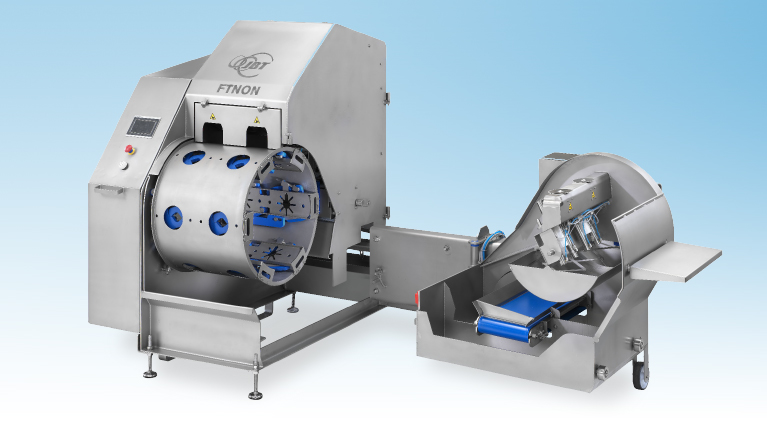

Maximize production and take advantage of low-maintenance versatility with our steam-pressure Saturno tomato peeler

Our JBT Saturno tomato scalder/peeler is designed to peel and process large quantities of tomatoes efficiently and precisely. You can achieve maximum productivity with minimal effort, thanks to the machine’s simple controls that allow you to easily adjust the scalding time according to the initial or final characteristics of the product.

Despite its impressive throughput capacity, the Saturno peeler ensures you don’t have to sacrifice quality for increased yields. Our expert engineers developed the machine to accommodate a diverse range of processing needs, applications, and end-product categories. By setting the optimal thermal cycle, the scalder/peeler can process different tomato varieties and maturities with very little operational requirements.

The machine is also built with durability, consistency, and cost-savings in mind. In keeping with JBT’s long-standing tradition, the Saturno peeler was designed and built to limit downtime and minimize costly maintenance and cleaning requirements, reducing the overall cost of ownership.

Features & Benefits

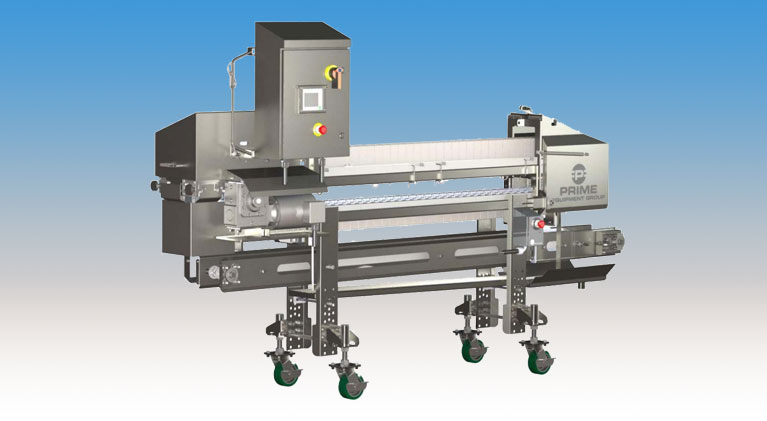

The Saturno Peeler allows you the freedom to customize its processing power, giving you greater flexibility and increased efficiency. Crafted with care and precision, this machine protects the integrity of your end-product at every level while optimizing your throughput capabilities.

Some key benefits of the Saturno Peeler include:

- High peeling efficiency – The Saturno peeler is capable of producing quantities up to 50-55 MT per hour, increasing your throughout potential.

- Superior end-product quality – With a hygienic design and state-of-the-art materials, your product will retain its freshness and quality through the entire process.

- Flexible configurations – The system can effectively operate in diverse conditions, allowing you to choose the optimal configurations for your processing system.

- Sustainable design – By exceeding global standards of energy efficiency, the Saturno peeler will allow you to contribute to a greener world without sacrificing processing power.

- Reduced maintenance costs – The machine is crafted for easy cleaning and maintenance, allowing you to save money and time.

Peeling in Diverse Conditions

The Saturno scalder/peeler empowers you with the ability to peel a variety of different tomato types and maturities with ease, under diverse processing conditions:

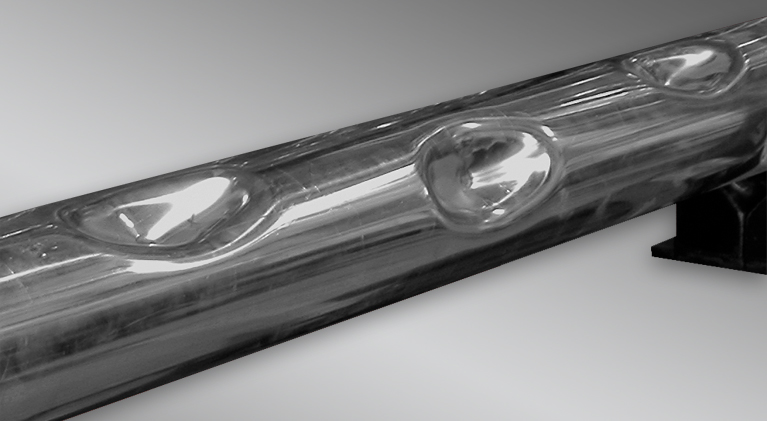

- Tomatoes can be steam-pressure scalded, immersed in overhead water, and then vacuum-cooled.

- Tomatoes can be steam-pressure scalded and then vacuum-cooled.

- Tomatoes can be scalded through immersion in overhead water and then vacuum-cooled.

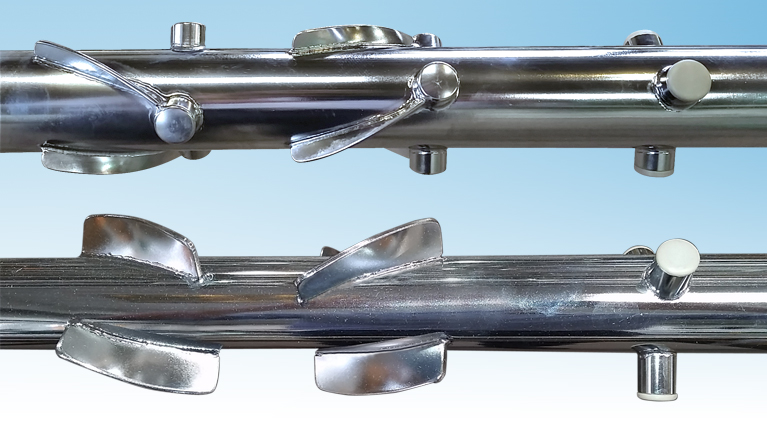

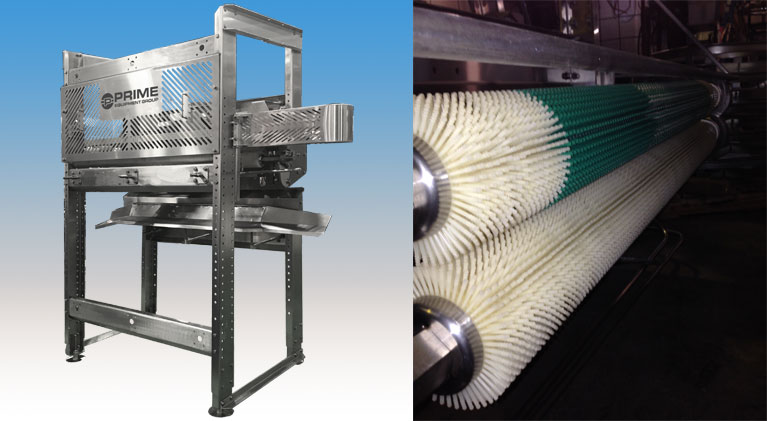

These three systems allow you to maximize peeling yield according to the type of tomatoes being processed and depending on your end-product objectives. If any remaining tomato skins are still attached to the fruits following the above processes, they’re removed by special, highly effective peel separators located at the outlet of the vacuum-cooling valve for maximum consistency and quality.

FAQs

What are the size specifications of the Saturno peeler?

The Saturno peeler is a high-powered processing system. Therefore, ensuring your floor plan can accommodate its size is essential to achieving efficiency. Its approximate measurements are:

- Height – 7,000 mm

- Length – 14,000 mm

- Width – 5,000 mm

How does the system improve peeling accuracy?

In order to ensure precise removal of skins for each and every unit, the Saturno peeler boasts highly effective peel separators located at the outlet of the vacuum cooling valve. This functions as an additional step after initial peeling to ensure that any residual skins stuck to the product are removed for maximum efficiency.

Does JBT provide training for this machine?

Yes! While JBT is known for our cutting-edge equipment, we’re more than just a manufacturer. We take the time to ensure that each of our customers has the knowledge they need to get the most out of their machine. We provide staff training on operation and maintenance. You’ll also have access to our expert support team for ongoing information, insight, and maintenance and repair services.

JBT: Targeted FoodTech Solutions & Comprehensive Support

Ever since JBT first got its start in the FoodTech space, our core values have remained the same. We strive for progress, transparency, integrity, and collaboration in everything we do. We’re committed to relentless innovation across diverse markets, and we’re always looking for inventive ways to improve existing technologies and create new automated solutions to help our partners achieve greatness while saving time, money, and energy.

With JBT, you’ll get the chance to:

- Make selections from an extensive catalog of premium equipment

- Customize and optimize your production lines and configurations

- Integrate equipment from a variety of industry-leading brands

- Take advantage of JBT’s world-renowned personalized services

- Access replacement parts, upgrade kits, service and maintenance, and specialized training to keep your operations running smoothly

Join Us at Our Cutting-Edge Research Centers

One of our main goals is to build long-lasting, collaborative relationships with our amazing partners. We know our success depends on your success, and we believe that together, we can create a brighter future. We invite you to visit our innovative Research and Technology Centers. We operate over a dozen facilities around the world, where you’re welcome to work one-on-one with our experts, explore our newest technologies, test new equipment, and experiment with different production-line configurations.

Take Advantage of Our Industry-Recognized Support Team

With over 100 years of experience in FoodTech, JBT has made a name as a true leader and reliable partner to producers in diverse, competitive industries. We understand that helping you meet your goals is essential to our success. That’s why we offer ongoing, expert customer service to all of our partners.

Our incredible, globally-recognized support team is known for its in-depth knowledge and personalized, detail-oriented approach. They’re available 24/7 to offer you the assistance you need at any time. Contact us today to learn more about our services.