Bevcorp Deaeration & CIP Systems

Vacuum Deaeration

The Bevcorp vacuum deaerator is the most common form of deaeration used in meter-based blenders to achieve the lowest dissolved O2 value possible. The deaerator is a “vacuum/recirculation” type oxygen removal system with CO2 injection.

Advantages:

- Can supply from .75 to 1.2 ppm O2 content, depending upon water temperature

- Contains an atomizing diffuser in the water inlet to the deaerator allowing the water to give up most of the entrained gasses

- The elimination of entrained gasses from the water facilitates CO2 absorption in the mixed product

- Smaller footprint

- Less installation cost

- Deaerator and discharge piping are cleaned during CIP

- Historical data trending and reporting

CIP/Deaerator Integration

The Vacuum Deaerator has the capability of optional CIP functionality built into the same skid package. The existing vacuum tank becomes the CIP reservoir. The result on a conventional CIP system is a lower overall hardware cost limited to the heat exchanger with controls, the return and outlet temperature and chemical strength instrumentation. The operator interface is PC-driven with historical data collection and reporting.

- CIP functions are built into the vacuum deaerator skid by permitting the existing vacuum tank to become the CIP reservoir.

- Utilizes existing footprint, electrical and process piping connections and distribution pumps

- PC-driven operator interface with historical data collection and reporting

- Deaerator and discharge piping are cleaned during CIP

- Smaller footprint

- Lower installation cost

Audits

Bevcorp process engineers can audit your systems to identify equipment capabilities and deficiencies in blending units, service utilities, and refrigeration systems.

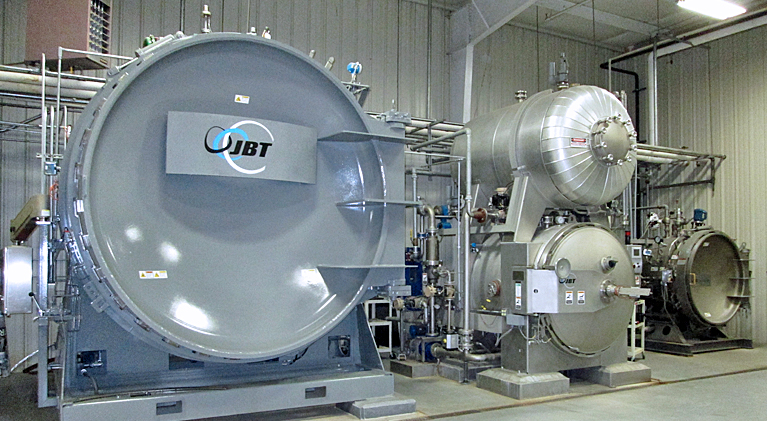

JBT Deaerator

When processing fruit juices and nectars, entrapped oxygen in the product after packing can seriously harm its quality. Flavored or enriched dairy products can be deaerated during the UHT process and greatly improves the product’s quality and shelf-life in these cases. Our deaerator vaporizes the product in a low pressure environment, which effectively separates all oxygen from the product. The vapor is then condensed and the aromas flow back into the system.

Features & Benefits

- Improves overall boiler room efficiency

- Removes carbon dioxide as well as oxygen

- Compact design means smaller boiler room requirements

- Integrated monitoring and control systems are available for the deaerator

- Raises the boiler feedwater temperature, eliminating thermal shock in boilers

Details

- Handles most liquid foods in order to maintain flavors and aromas during processing

Options & Models

- Can be equipped with a stirring mechanism to handle products with particles

FranRica™ Aseptic Flash Cooler

Our FranRica Aseptic Flash Cooler is today’s cutting edge technology in the field of aseptic sterilizers.With heat transfer occurring through direct steam injection and thermal flash in a vacuum environment rather than with heat exchangers, scaling-related problems on exchange surface are eliminated.With our reduced product degradation and long term aseptic set-up, you truly feel the effectiveness of our Flash Cooler in action.

Features & Benefits

- Low maintenance costs

- Long term aseptic operation

- Minimizes product degradation

- Direct Heating/Cooling technology

- Continuous aseptic processing system

- Simple to operate and repair; few moving parts

Details

- Handles high production volumes (surge capacity)

- High production throughput between 3,500-60,000 kg/h

- Typical applications for the FranRica Flash Cooler include aseptic cooling of tomato and fruit concentrates

Options & Models

Homogenizer

Our specially-designed homogenizer is a powerful, high-pressure pump, especially designed for use in UHT sterilization systems. By forcing the product through a narrow opening, larger drops of fat are broken up into smaller ones and are then spread evenly through the product. Additionally, the homogenizer is equipped with one or two heads, depending on the application and the product being processed.

Features & Benefits

- Long, economical lifetime

- Minimal maintenance costs

- Very versatile and easily adjustable

- Available in aseptic configuration

Details

- Best used for UHT white milk, UHT flavored milk, creams and juices

Hydromatic® Hydrostatic Sterilizer

Our Hydromatic Hydrostatic Sterilizer provides continuous processing of almost all container types and sizes including metal, glass, rigid and semi-rigid plastic, pouches.

Whether used for condensed soups or ready-to-serve meals, our sterilizer is ideal for processing products that require long cook and cool times, at high throughput, and especially for those deriving benefit from mild agitation.

Features & Benefits

- High volume process capabilities of cans, glass, plastics and pouches

- Uniform and consistent process conditions for high product quality

- Highly efficient energy usage

- Fully automated handling with minimum operator involvement

- Proven high reliability and low maintenance cost

- Minimal floor space usage

- Easy, continuous in-plant-logistics

- High process flexibility by adjusting time, temperature and pressure conditions

- Solutions for wide variety of package types and dimensions

Details

Used for highly dense foods requiring little to no agitation and long process times:

- Condensed soup

- Moist pet food

- Long-life dairy and soy drinks

- Vegetables and Ready-to-Serve meals

- Fish and meat

- Low-acid drinks in cans, glass, HDPE and semi-rigid containers

Options & Models

Hydromatic RCS

This system is specifically designed for high capacity processing of products that benefit from agitation during the cooking and cooling phase

- Low-acid drinks in cans, glass, HDPE and semi-rigid containers

- Long-life dairy and soy drinks

- Juices

Hydromatic® ZCS

Our Hydromatic ZCS Sterilizer provides a highly efficient continuous processing solution specifically suitable for glass and plastic bottles. It maximizes large capacity processing of bottles with any type of retortable closure. The bottles are placed in individual pockets during processing, preventing impact and damage to the closure and allowing for mild end-over-end agitation in upper- and under-bends of the chain path. Use our system for short sterilization times in the range of 10-20 minutes.Used for pasteurization and sterilization of drinks in bottles with relatively short process times:

- Dairy drinks

- Yoghurt

- Non-carbonated beverages

- Soy drinks

- Juices

Hydromatic® Unicon

Used for highly dense foods requiring little to no agitation and long process times:

- Condensed soup

- Moist pet food

- Long-life dairy and soy drinks

- Vegetables and Ready-to-Serve meals

- Fish and meat

- Low-acid drinks in cans, glass, HDPE and semi-rigid containers

Pilot Sterilizers

Multi-Purpose Laboratory Sterilizer

Our Multi-Purpose Laboratory Sterilizer has the flexibility to simulate batch (static and agitating), hydrostatic and continuous rotary sterilizer production units. It is capable of accurately simulating all types of production sterilizers engineered and built by JBT. This system provides food processors with the capability and flexibility to accurately design thermal processes using the type of equipment that best fits the requirements of the product instead of forcing the processor to reformulate a product to fit a certain type of sterilizer.

Features & Benefits

- User-friendly

- Minor clean up and sanitizing costs

- Minor installation and start-up costs

- Precise and reliable process modeling

- Precise, reproducible execution of pre-programmed recipes

- Flexibility to accurately simulate all types of production sterilizers engineered and built by JBT

Details

- Retorts are at the heart of many shelf-stable food processing lines such as:

- Milk

- Fruit Juices

- Tea, Coffee

- Soups, baby food, pet food

- Ready-meals, astronaut food

- Sauces etc.

Options & Models

- A091

- A092

- AR091

- AR092

Pilot Rotary Laboratory Retorts

Our Pilot Rotary Sterilizers, including the 804 – Steritort pictured above, enable processors to accurately design thermal processes and conduct trials in a pilot plant environment.

Features & Benefits

- Enables processors to accurately design thermal processes by replicating the effect of time and temperature variables on canned food products

- Conducts pilot plant studies simulating the type of equipment that best fits the requirements of the product

- Rotary Atmospheric, and Rotary Pressure simulations can be conducted to determine requirements for specific products

Details

- Evaporated milk

- Cream

- Ready-meals and ready-to-eat soups

- Sauces

- Vegetables and fruits

- Rice based products

- Beans in sauce

Options & Models

- 610-B

- 804 – Steritort

- Megatort