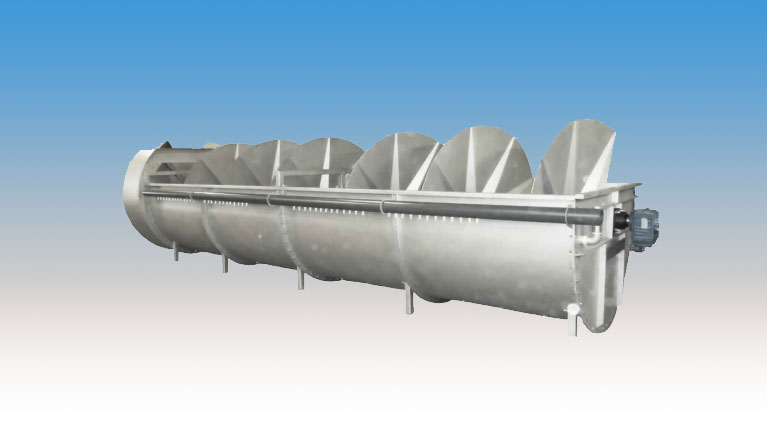

Our Prime Chicken Keel Cleaning System efficiently separates meat from cut chicken keels, producing a clean keel product that is ready for shipment or processing. Keels are pumped to a specially designed picker-scalder, where heated water and fingers separate the meat. Keels flow to processing, while the process water is screened to remove solids and re-circulated back to the picker-scalder for water and BTU savings.

Features & Benefits

- Separates meat from cut keel

- Prepares clean keels for processing

- Screen/tank system separates meat from process water and re-heats water for re-use

- Complete system for keel cleaning offers high through-put and ease of use

- Water separation tank is designed to conserve water and heat for low cost of use

Details

- Electrical Requirements:

- KPS-1: Drive- (1) 15 hp, 480V, 3 ph, 60 Hz

- Spray bar pump- (2) 7.5 hp

- LPS-112: Drive – (1) 1.3 hp, 480V, 3 ph, 60hz

- Spray bar pump – (1) 20 hp

- Steam Unit Requirements: Electrical: 20V, 1 ph, 10 amps

- Air Requirements: 100 psi 1/4-inch NPT connection

- Water Requirements: 350 gallons to fill holding tank; additional make-up water during operation

- Production capacity: 25 pounds of keel per minute

- Weight:

- KPS: 1,800 lbs empty; 2,400 lbs full

- PPS: 1,800 lbs empty; 2,200 lbs full