Discover superior chicken processing solutions with JBT’s CSKB-1 Belt Skinner

The demand for skinless chicken breasts in U.S. markets is growing rapidly and isn’t showing any signs of slowing down. Because of this ever-expanding opportunity, now is a good time to reevaluate your processing system for chicken breast production.

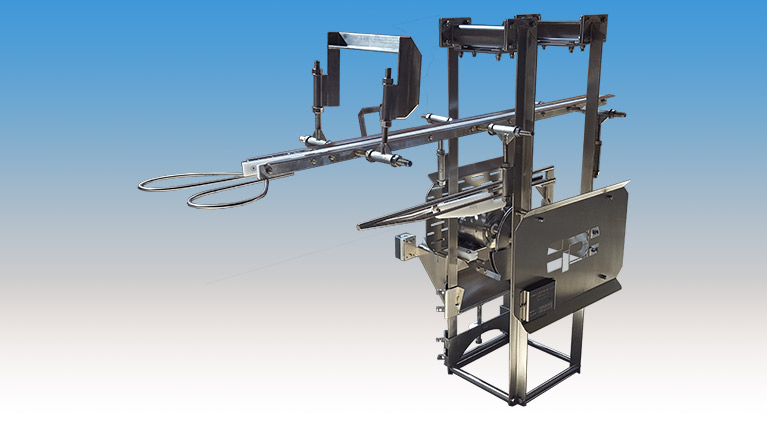

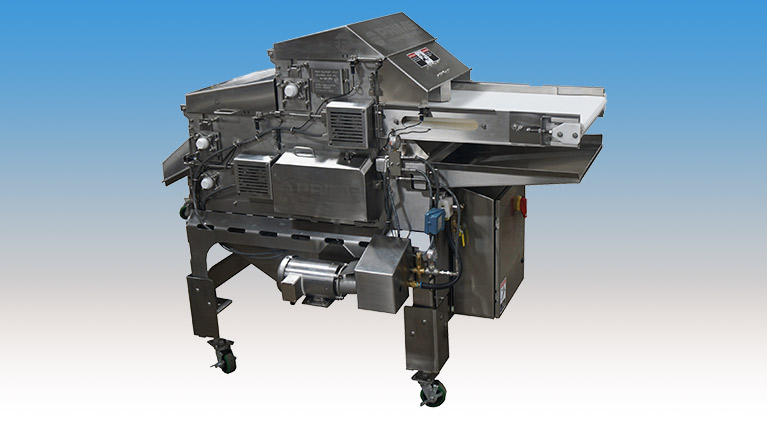

JBT’s CSKB-1 Belt Skinner is a high-tech, automated skinner that is guaranteed to offer you more productive yield and increase your profits. This revolutionary machine utilizes a simplified, streamlined design to provide you with quicker, more efficient, and safer applications. Traditional paddlewheels and extensive manual labor will no longer impact your bottom line. With a modern hygienic design and a simplified control system – including a flighted, non-modular belt and fewer parts – you’ll get a head start in a growing market while cutting labor and maintenance costs at every stage.

Features & Benefits

The all-new JBT-Prime CSKB-1 Belt Skinner will revolutionize your chicken skinning process. Its safe and hygienic design, high yields, and low maintenance requirements will give you the productivity boost you need to gain the upper hand in a competitive and fast-growing market. Here are a few of the benefits of integrating the CSKB-1 Skinner into your production line:

- Cost-effective – The machine’s simplified control system, with fewer parts and a non-modular belt, makes it easy to operate while cutting labor and maintenance costs.

- Sanitary – The skinner’s flighted, non-modular belt is much more sanitary than a traditional paddlewheel design. You can quickly and easily access all the machine’s food-contact components, helping you achieve the highest microbiological standards.

- Efficient – With minimal maintenance requirements, easy cleaning, and a simple, efficient design that maximizes uptime and limits product loss, you’ll see increased productivity and higher yields.

- Safe – The CSKB-1 skinner is outfitted with the most up-to-date safety features, including an array of pinch-point elimination guards to help maximize operator safety.

- Low maintenance – The innovative design greatly reduces maintenance and setup time, increasing productivity and lowering the cost of upkeep substantially.

- Easy to clean – The skinner’s non-modular belt helps eliminate the risk of bacteria; simply slip the single-piece belt off the machine to clean and sanitize.

Simplicity Meets Efficiency

The CSKB-1 Belt Skinner is designed to maintain the highest standards of end-product quality while improving operator safety and maximizing output. Its sleek, simple design dramatically reduces wear parts, minimizing repair and maintenance requirements and reducing replacement costs to almost zero. The simple design – with a single, permanent magnet drum motor and no upper assembly – ensures a robust system with fewer components that’s easier to clean, operate, and maintain.

The simple design also provides easy, quick access to all food-contact components, while the non-modular belt reduces bacteria traps. This sanitary design helps you meet the most rigorous hygiene standards.

Find a Trusted FoodTech Partner in JBT

With over a hundred years of experience developing food-processing equipment, JBT has remained dedicated to breaking barriers and revolutionizing what is possible in FoodTech. With us by your side, you’ll have access to the highest-quality and most innovative processing equipment on the market, helping you make all of your business goals a reality.

Success Through Meaningful Collaboration

At JBT, we know that we can only be as successful as our business partners. Together, we can redefine food production and work towards a brighter, more sustainable world for all of us.

Diverse Global Markets

Our extensive insight into the food processing industry has developed from our hands-on experience in a wide range of markets around the world. We take the time to understand each client and each market so that we know how best to serve our partners.

We work directly with clients in several distinct markets, including:

Hubs of Innovation & Collaboration

When you work with us, you gain coveted access to our Research & Technology Centers. We operate over a dozen RTCs around the world, where our specialists have conducted tens of thousands of application tests and are always available to work with our partners to identify and implement improvements to their products and processes.

At these innovative labs, you’ll have the opportunity to try out new equipment and production-line setups, hone your recipes, and receive world-class technical guidance, expertise, and data.

Connect with JBT Specialists

For more than a hundred years, JBT has defined and redefined what’s possible in the FoodTech industry. Throughout our history, we’ve collected and analyzed an incredible amount of data, developed trusting and enduring partnerships around the globe and gained a tremendous wealth of experience and knowledge. We want to share what we’ve learned with you.

Together, we can carve out your competitive edge in your particular industry and markets while also building toward a better future for FoodTech and consumers around the world.

With these shared goals, JBT is your go-to resource. We know how demanding food production is, and we’re here to deliver the highest quality machinery, service, and support to ensure you meet and exceed your goals. Don’t hesitate to contact us anytime. We’re at your service.