Modernize your control systems to increase efficiency, boost profitability, and get the most out of your production line

The FoodTech industry faces unique challenges. While technological advancements and automation have brought significant improvements in food processing solutions, standard modern systems often bring complications to companies. Product inconsistencies, lower yields, inaccurate data, and unpredictable labor and maintenance costs are just a few of the concerns faced by those in the industry.

At JBT, we have a unique understanding of the practical needs of our partners and we’ve used our insight and industry know-how to develop smart control systems that tackle modern food-processing challenges. Our efficient monitoring and control systems work cohesively to address inefficiencies and provide superior usability and functionality.

Our systems utilize effective, automated data-processing methods to integrate seamlessly with your current process, providing you with targeted solutions that reduce maintenance needs, increase labor efficiency, expand overall throughput, and provide greater accuracy and product consistency.

Give Your Processing Line an Intelligence Boost

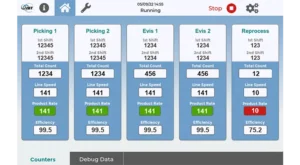

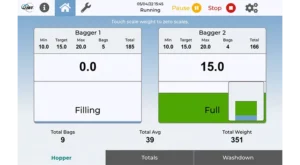

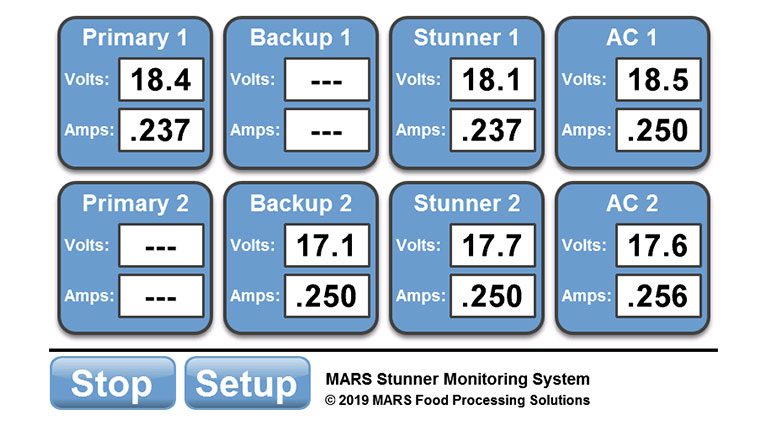

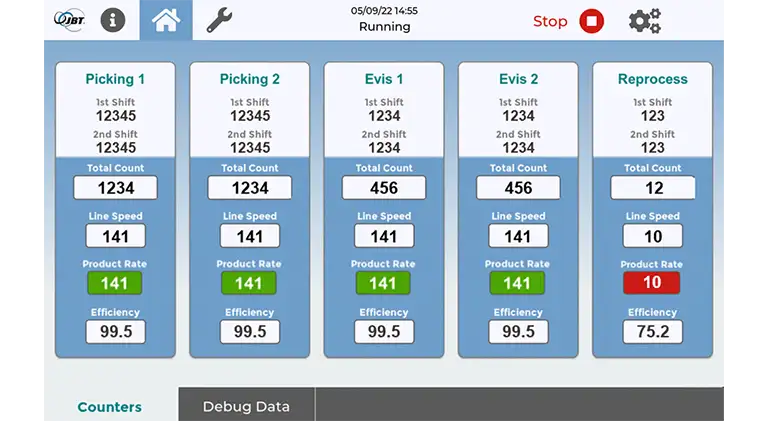

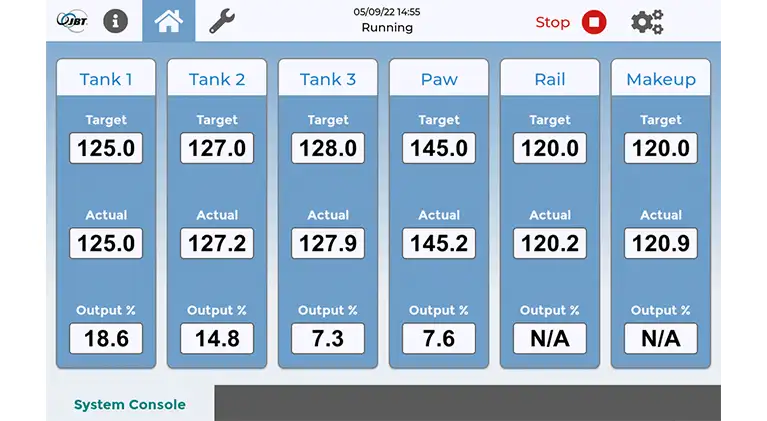

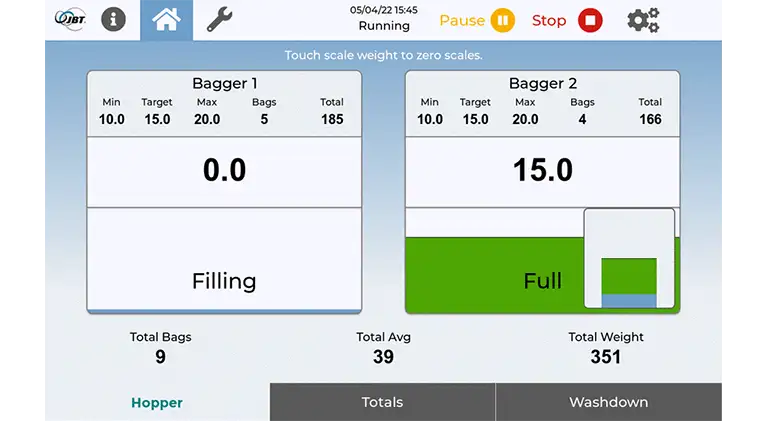

With JBT’s advanced control systems, you’ll be able to monitor, manage, and share your processing line’s data across your plant’s devices and screens as well as to other global locations. Using our high-speed scales and advanced sensors, you can track and process your data (including temperature, pressure, amperage, voltage, and more) with increased speed, accuracy, and consistency.

Our cutting-edge technology integrates seamlessly into your existing infrastructure, providing you with valuable insights that will help you improve uptime, reduce inefficiencies, increase productivity, and streamline your operations.

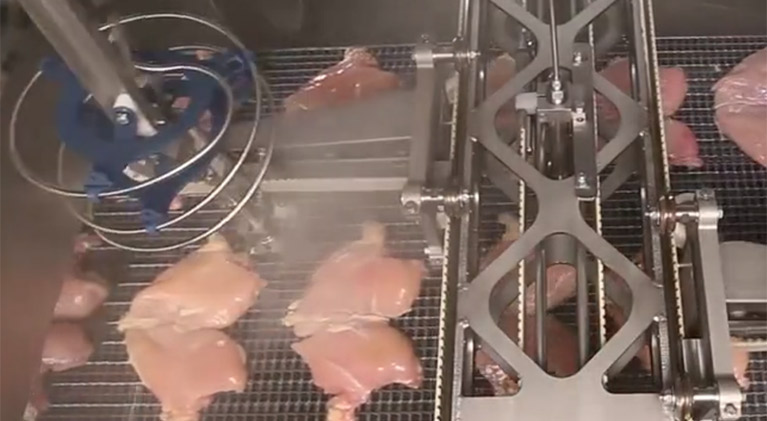

JBT’s Advanced Protein-Processing Control Systems

The modern consumer has high expectations. Regulatory standards are stricter than ever before. Environmental and market pressures are extreme. JBT’s high-tech control systems enable you to rise up and face the extreme demands of the protein-processing industry head-on.

Decades of rigorous research and development have led us to the advanced technologies we offer in the protein-processing space today:

- High-speed scales can process data (temperature, pressure, amperage, voltage, etc.) faster and more accurately than ever.

- Weighing is more precise and consistent thanks to new cutting-edge system modules, chops, and processing units.

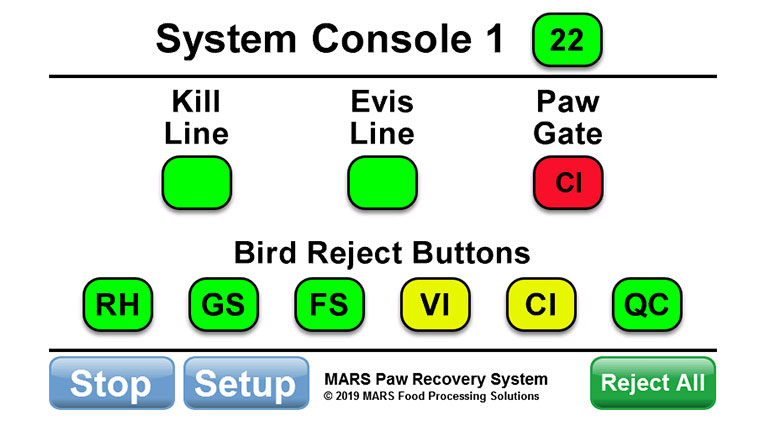

- Modern displays allow users to visualize, monitor, and manage processing in real-time.

- Easily removable SD cards allow you to reprogram controllers at any time.

- An ethernet connection enables remote monitoring, diagnostics, training, and software updates.

All this and so much more is possible with JBT’s protein-processing control systems.

JBT – Your Partner in FoodTech

The food processing industry is diverse and dynamic. That’s why teamwork and reliable partnerships are key to your success, and ours. We have spent over 100 years innovating revolutionary technology, but we have also maintained a unique focus on developing consistent and mutually beneficial business relationships. When you work with us, you get more than just high-tech machinery; you’ll also get a trusted partner that is committed to providing real-world insight and expert support to help you increase your bottom line and improve your operations.

With us, you can:

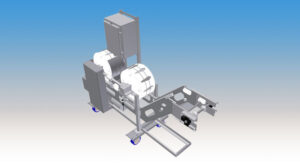

- Look through our extensive line of cutting-edge machines

- Develop a system that is customized to target your specific needs and concerns

- Mix and match equipment from a range of manufacturers to enhance your system

- Quickly get replacement parts and upgrade individual components to maintain prime operations

- Access diverse services such as upgrade kits, parts, service and maintenance, and training

Superior Solutions Across Industries

Over the last several decades, JBT has had the privilege of partnering with companies from all over the world, across a wide range of industries. Our diverse clientele and extensive experience has given us unique insights and helped us develop a comprehensive understanding of various food and beverage markets, including:

Join Us at Our Research & Development Centers

As a JBT partner, you’ll have access to our highly sophisticated Research & Development Centers. With over a dozen internationally-based facilities, you can get a close look at how we operate behind the scenes. You’ll get to work directly with our specialists to develop effective, high-quality, and personalized solutions. At our centers, you can test new equipment and system configurations, perfect recipes, and design a solution plan that works for you.

Reliable Support

JBT has made a name for itself not only for our work in creating high-tech food processing equipment, but also for our unrivaled customer support. Whether you need insight into market trends, practical maintenance and training procedures, or new technology to optimize your production line, we make it our goal to provide our partners with everything they need to succeed in any market.

Contact us today to inquire about our services and get the knowledge and expertise to accomplish your goals and exceed expectations.