Top-of-the-line freezing and chilling equipment to maximize safety, quality, efficiency, and profits

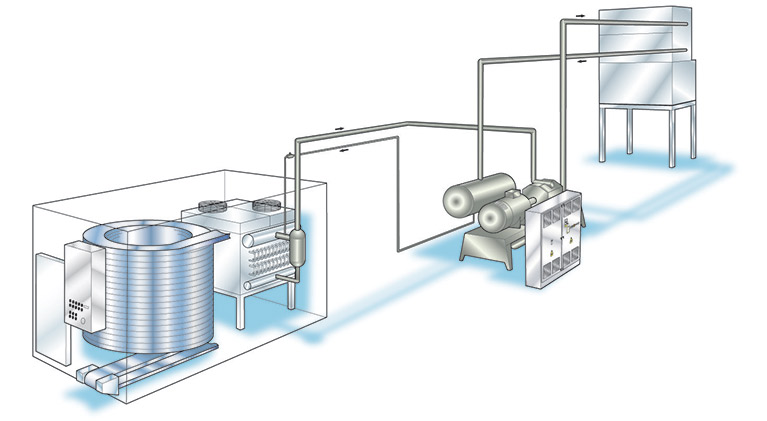

When it comes to primary food processing, freezing, chilling, refrigeration, and proofing systems are essential to developing superior products. Having reliable, quality equipment that can get the job done right is a necessity and an invaluable key to your competitive advantage. JBT has gone above and beyond to create products that target the needs and concerns of industry professionals like you.

With our state-of-the-art chillers and freezers, you can rest assured that our machines will meet the highest standards of product safety, hygiene, and taste, all while reducing labor and maintenance costs and increasing profits. Our equipment is cultivated to maintain premium operating functions while offering you abundant control and options to optimize your production and meet your specific goals.

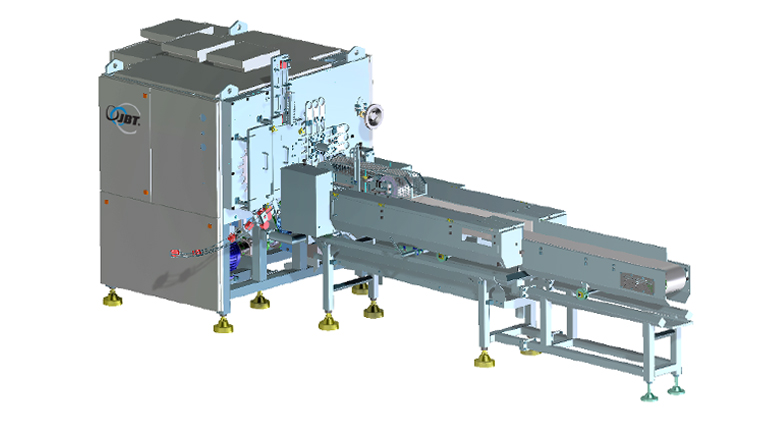

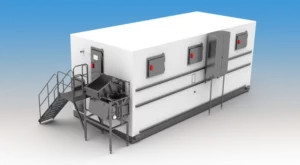

With virtually endless customizable configurations, upgraded technology, and unparalleled adaptability, we have redefined standards of cooling and proofing processes.

Optimize Your Operations to Boost Profits

At JBT, our business model has always focused on developing new and better food-processing technologies that 1) improve efficiency and reduce the cost of equipment ownership and 2) produce the highest possible end-product quality. By harnessing the power of innovation and automation, you can limit production costs and maximize profits.

We strive to provide you with freezing, chilling, and proofing technologies and solutions that run like clockwork, deliver maximum uptime, meet and exceed the highest standards of food safety, and make processing easy and convenient. Our solutions are designed to ensure you don’t have to compromise or cut corners elsewhere to take advantage of the world’s best freezing and chilling technology.

Features & Benefits

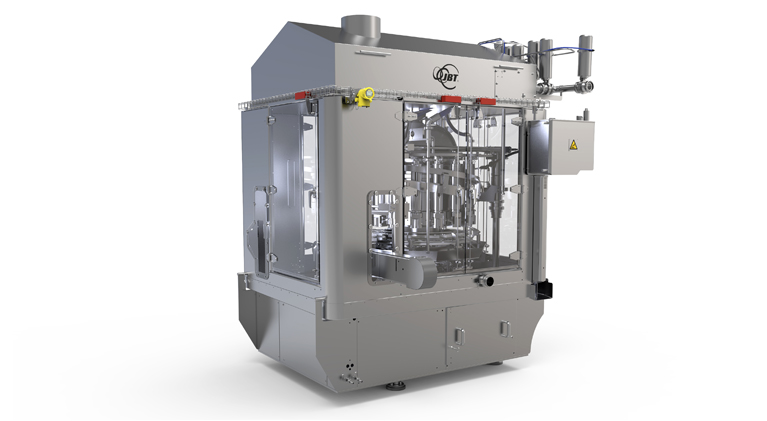

JBT’s innovative line of freezing, chilling, and proofing equipment is expertly designed and engineered to meet the industry’s toughest food safety demands. Our decades of experience and extensive food-processing knowledge allow us to effectively respond to customer needs and demands by delivering cutting-edge solutions that make processing easy for you and your operators, maximize uptime, and improve your bottom line.

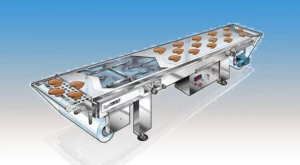

- Consistent – When it comes to freezing, cooling, and chilling, reliability and consistency are key. Our machines deliver quality, uniform results every time.

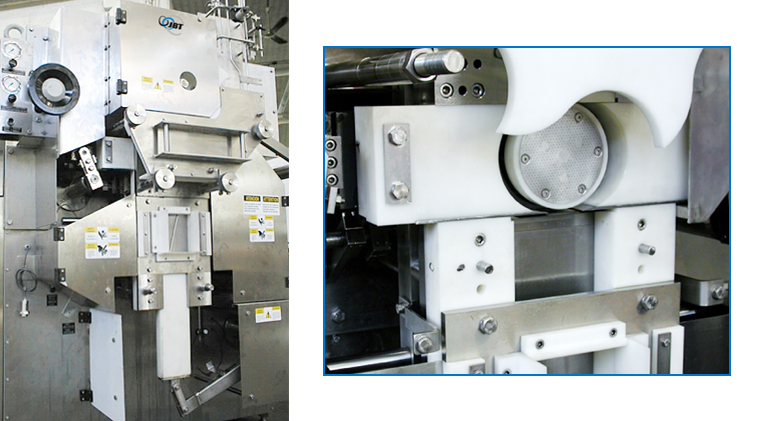

- Hygienic – All JBT equipment is built with food safety and hygiene in mind, and our range of freezers and chillers is no exception. Consider adding our automated Clean-in-Place (CIP) technology to the NEOCAT Chiller to maximize uptime and substantially reduce cleaning costs.

- Efficient – Designed with energy and cost savings in mind, our freezing and chilling systems offer enhanced performance and efficiency, saving you valuable time and resources.

- User friendly – Advanced engineering and innovative design improve safety and ensure reliable, trouble-free operation. With precise temperature and environmental controls, you have the flexibility you need to produce superior food products at a low cost.

- Customizable – Built for high-volume freezing, chilling, and cooling of a wide range of food products, JBT’s state-of-the-art freezers offer flexible configurations and a variety of belt types to optimize food handling and sanitation.

JBT – Your Partner in FoodTech

For more than 100 years, JBT has been innovating and pushing the limits of what’s possible in FoodTech. We’re committed to solving the industry’s toughest challenges, and that starts with an in-depth understanding of the needs and goals of our partners. That’s why we’re so focused on building collaborative, long-term relationships with our clients. When you work with JBT, you get more than just cutting-edge equipment – you get a partner that makes your success their mission. Together, we can achieve great things.

Targeted Solutions for Competitive Food Markets

JBT is all about developing and delivering cutting-edge technologies and approaches to food processing that help our partners achieve greatness and gain a competitive edge in some of the most demanding markets on Earth.

Over our decades of experience, we’ve accumulated a wealth of knowledge and expertise about a wide range of distinct markets and gained unique perspectives and insights into them. These markets include:

Working Together for Mutual Success

We see you as so much more than just another customer. At JBT, we’ve learned from over a century of experience in FoodTech that, by working together with our trusted and valued partners, we achieve more individually and together. We know that the best way to meet our goals is to help you achieve yours.

We’re committed to sharing our cutting-edge equipment, accumulated knowledge, expert guidance, and industry leadership with you to empower you to face and overcome the toughest challenges in your unique industry and markets. By partnering together, we can build a stronger, better future for all.

Come To Our Advanced Research & Technology Centers

Our mission has always been focused on providing real-world solutions through innovation – and we want to share our process with you. As a JBT partner, you’ll have the opportunity to visit any of our Research and Technology Centers around the globe. There, you’ll work face-to-face with our experts to test equipment and system configurations, fine-tune your recipes, and get a unique insight into the industry.

JBT’s Globally Recognized Support Team

With JBT, you’ll have access to expert assistance 24/7 with our unmatched support team. Our dedication to our partnerships goes far beyond equipment production and installation. We make it our mission to provide consistent, quality support in every aspect of food processing.

Call our team anytime to get advice from industry experts, receive specialized maintenance assistance, and continue to improve your system every step of the way. Contact us today to get started.