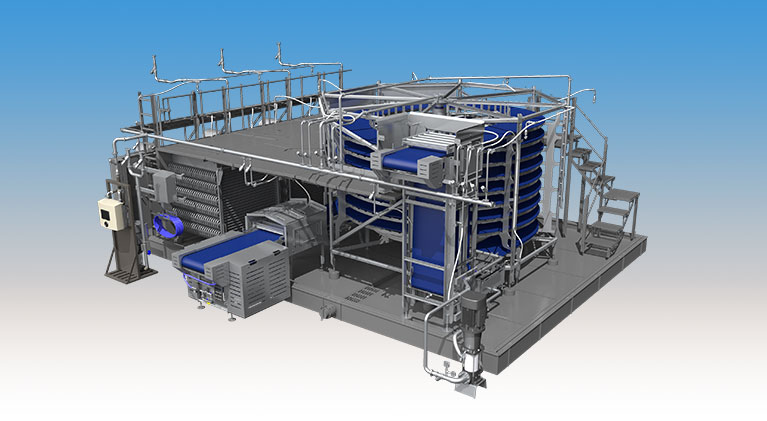

Innovative and sanitary solution for quick, high-volume freezing, chilling, and cooling of a wide range of food products

JBT, The Hot Choice in Quick Freeze Freezers

In the past, rapidly chilling and freezing large quantities of food was a monumental task. And doing so, safely, efficiently, and cost-competitively was near impossible. On top of that, keeping your set-up clean and maintained was an extra-burdensome chore.

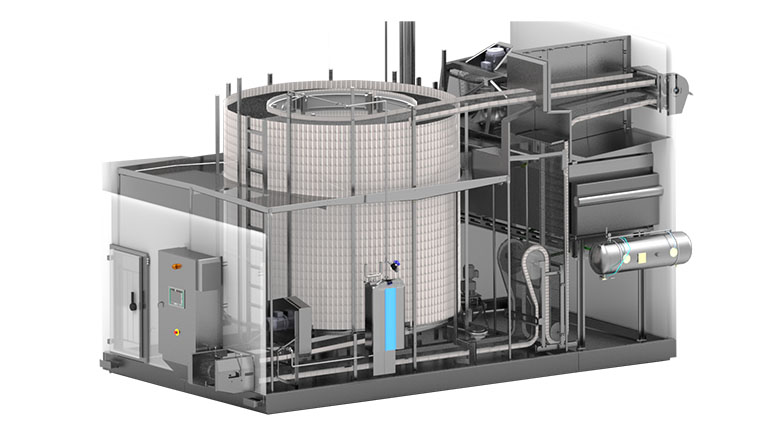

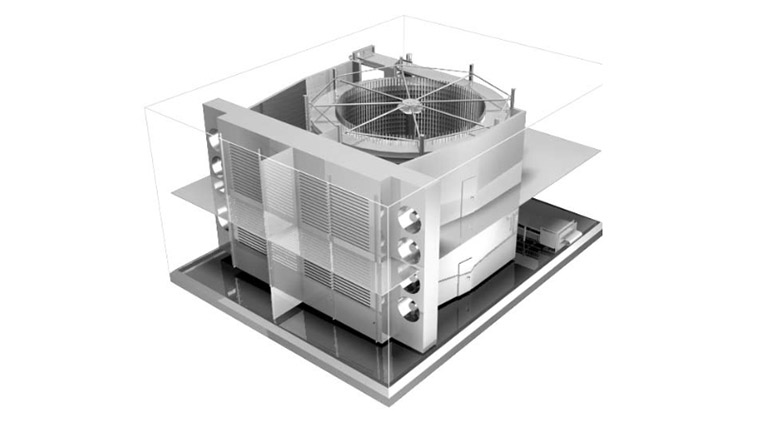

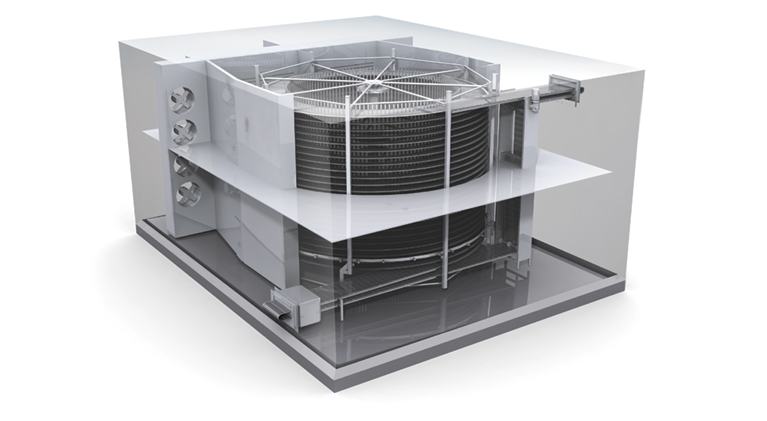

Thankfully, the CleanFREEZE freezer (formerly known as the Northfield SuperTrak Structure Supported Freezer) is robust enough to take on present-day demands. It’s flexible enough to handle tomorrow’s needs as well.

JBT’s CleanFREEZE is a shining example of innovation in the high-volume freezing, chilling, and cooling. As a next-generation freezer, it accommodates a broad assortment of both packaged and individual quick freeze (IQF) food products. The CleanFREEZE is regularly used in applications such as:

- Poultry — Raw, par-fried, and fully-cooked whole-muscle and formed chicken products

- Beef and pork — Raw and fully-cooked hamburger and sausage patties, links, and ground products

- Pizza — Both plain crusts and fully-topped pies

- Bakery — Breads, cakes, pies, donuts, and bagels

- Ready meals in trays — Everything from single-serve to family-size entrées

- Handheld snacks — Meat-, cheese-, or fruit-filled treats

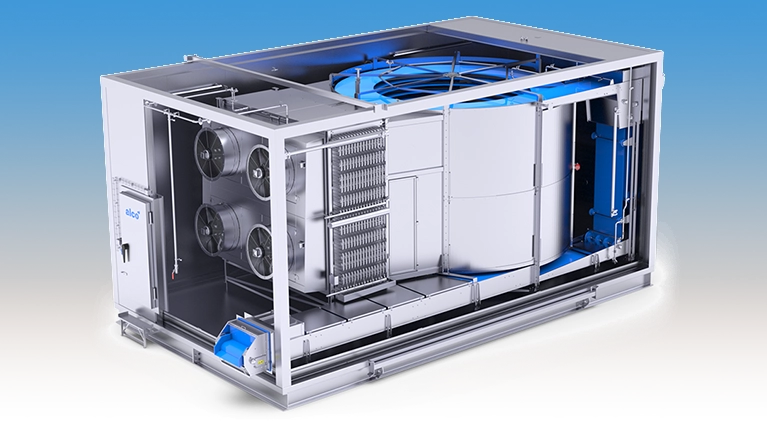

Food processors also really appreciate the sanitary design, superior performance, and easy upkeep of their CleanFREEZE. Here are just some of the marquee attributes that set the Northfield CleanFREEZE Spiral Freezer apart from others:

- Uptime is optimized with a cold-to-cold turnaround time of four hours.

- Fully welded enclosure, minimal overlapping joints, and an open-profile frame and sloped surfaces minimize bacteria traps.

- Capless, solid plastic rails reduce bacteria potential in the product zone.

- Externally-mounted fan motors eliminate contact with products for better hygiene and easier maintenance.

- Advanced design cuts installation time by up to 30% over previous models.

With JBT in house, you’ll be able to optimize operations, which could help you meet your yield, quality, and throughput goals. Better still — you don’t have to sacrifice food safety, product shelf-life, or cost per unit.

Features & Benefits

The CleanFREEZE from JBT is loaded with all the features you could want or need in a refrigeration or freezing system.With this functionality on tap, you can consistently and predictably process products quickly, accurately, and safely.

- Hygienic — Sanitary design provides peace of mind and ensures product safety

- Ownability — Externally-mounted fan motors and stairs instead of ladders for easier, safer maintenance

- Safety — Smart design features discourage or prevent bacterial growth

- Fast — Optimized for a swift cold-to-cold turnaround time of just four hours

- Rollout — Latest model requires 30% less time to deploy

- Intelligent — Programmable to accommodate a wide variety of changing products

- Customizable — Modular and easy-to-integrate systems to meet changing product demands

- Controlled — Precise temperature and environmental controls produce superior food at the lowest cost

- Innovative — Built for speed, efficiency, and reliability

- Cutting-Edge — Advanced hardware and software allow for continually-improved capabilities and flexibility

- Support — Worldwide service, support, and resources

Contact our team with any questions about these features — or how they can benefit your business.

Smarter Design, Best Outcomes

Our years in the field and engaging with customers like you are evident in the design and building of our products. JBT sensibly and carefully incorporates smart features and functionality into our solutions for peak performance, unbeatable value, and hassle-free ownership.

JBT’s fixation on detail and excellence is a win for your business. Our world-class systems feature:

- Construction leveraging the latest techniques and best materials

- Incomparable durability and longevity

- Configurability for maximum adaptability

- Compatibility with other food processing equipment

- Less vulnerability to unplanned service interruptions caused by machinery issues

- More intuitive operation

- Shorter installation timeframe

- Greater resale potential

On the whole, JBT’s commitment to more intelligent design means you’ll enjoy productivity gains, yield increases, cost reductions and stability, and product quality improvements.

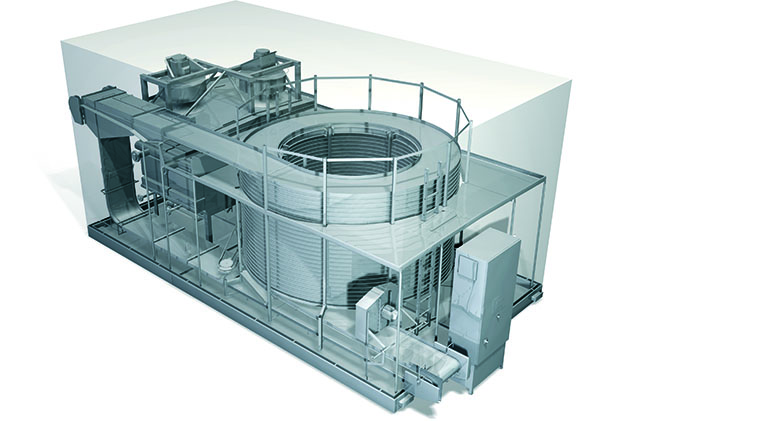

Northfield, A Proven Brand for Quick Freezers

If you want reliable equipment, you must opt for premium makes and models. Northfield has a long legacy of meeting and exceeding customer needs — it’s earned its reputation for dependability.

With over 40 years of development, engineering, and on-site expertise, Northfield has established itself as a renowned brand of structure supported spiral freezers. Modern design, material selection, and rugged construction are keys to the high-functioning and ease-of-ownership inherent to CleanFREEZE Spiral Freezers.

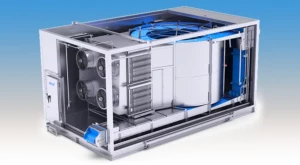

CIP — Optional Upgrade for Even Better Results

JBT’s Clean-in-Place (CIP) technology is a terrific add-on to your CleanFREEZE. Once installed, it can reduce labor costs and boost plant efficiency.

CIP drastically and immediately cuts the time, effort, and difficulty of sanitizing your freezer. For example, the new 90 GPM pump cabinet lets you run multiple cleaning circuits simultaneously, which washes away at least an hour of overall clean-in-place time.

JBT, More Than Just the Best Spiral Freezer Manufacturer

We’re willing to bet that your operation involves steps other than freezing. Not an issue.

JBT makes it easier than ever to put together a processing line tailored to your specifications. Our comprehensive portfolio of foodtech equipment and services can meet the eclectic needs of many sectors and use cases including:

Whether you’re buying one machine or one hundred machines, JBT has the quality, variety, and versatility you’re looking for. This means you’ll be able to:

- Source all your equipment from one supplier — how convenient!

- Customize your equipment selection to fit your requirements

- Mix and match brands to get a bespoke mix of machinery

- Replace or upgrade individual components with ease

- Nimbly respond to market or production changes

- More harmoniously scale your business

Beyond machinery, JBT also offers several great ways to pack the most value into your production facility. You can level up with upgrade kits, lubricants, and parts, service and maintenance, training, and support.

JBT, The FoodTech Partner You Can Chill With

Look no further. JBT can take care of all your food processing needs — we’re the one and only solutions provider you need.

It’s All About You

The success of your business is important to JBT, so we work diligently to build a collaborative long-term relationship with you. Doing so enables us to serve you more intentionally and holistically now and over time as your needs evolve. It’s a win-win.

Hubs of Innovation & Expertise

One stand-out perk of working with JBT — Our Research & Technology Centers aren’t mere test kitchens or food labs. The singular facilities — a JBT exclusive perk — are places where you can try out machines and processing line configurations, refine your recipes and methodologies, and get technical expertise and data. They’re game-changers!

JBT Expertise within Reach

As a foodtech pioneer and leader for over a century, JBT has accrued a huge amount of knowledge and experience. Leverage it for your own benefit! This extra level of support is available because we know running a food business is hard and we want to make it easier. Reach out to JBT’s talented team if we can assist you in any way.