Innovative design and a focus on targeted solutions make the NEOCAT Chiller the perfect addition to your production line by increasing performance and efficiency

At JBT, our comprehensive understanding of diverse industry needs and concerns has informed our ability to provide our partners with high-tech, functional, and revolutionary technology. Not only do we strive to craft practical and modern machines; we also work tirelessly to continuously improve machine capabilities and performance.

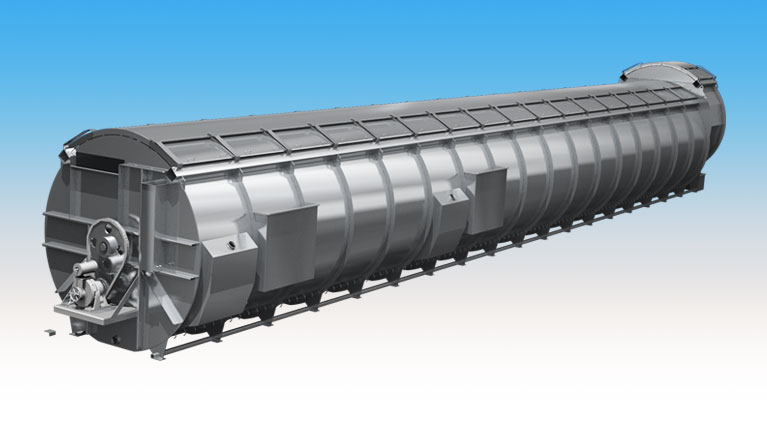

With the NEOCAT Chiller, we have refined and enhanced traditional chilling capabilities in poultry preparation. With our ingenious design, you’ll notice our attention to efficiency and consistency at every level. With increased output capabilities, a compact design, and state-of-the-art techniques that keep your product safe, clean, and fresh, the NEOCAT Chiller improves on the previous FATCAT Chiller and offers you an abundance of targeted features that will help you rise to the top of your industry.

Features & Benefits

The innovative design of the NEOCAT Auger Chilling System addresses some of the most pressing problems in whole-bird processing. It is designed with the goal of cutting costs and increasing your bottom line. The NEOCAT is perfectly crafted to target industry-specific concerns for those in the poultry, meat, and seafood industries.

Our attention to detail and thorough understanding of how production lines function has allowed us to craft a truly remarkable product. Here are a few of the key features and benefits of the NEOCAT Auger Chilling System:

- Increased capacity OR space-saving design – The NEOCAT’s innovative design saves valuable floor space by reducing your processing footprint by 30%. Alternatively, if you don’t need the extra space, you can opt for the traditional footprint, which increases the machine’s whole bird capacity by 30%.

- Natural and consistent flow – The new hanger bearing design keeps birds fully submerged, rather than floating on top of the water.

- Versatility – While mostly used for chicken, it can also be used for turkey and fish processing.

- Temperature Regulation – Birds remain at a more consistent temperature throughout processing.

Product Details

Efficiency is at the core of our mission with the NEOCAT Chiller. We offer several unique design features that prioritize throughput while also improving product integrity, quality, safety, and cleanliness. Every machine is not only expertly made, but also undergoes rigorous testing to ensure it meets the highest standards of performance and quality. Here are some important product details to consider:

- The NEOCAT’s footprint is smaller than your average auger system, measuring 8’ to 12’ in diameter (depending on what model you select), 95’ in length, and 10’11” to 14’11” in height.

- The system has no overhead structures, protecting your products from unnecessary damage.

- Improved water levels keep birds fully submerged and chilled while eliminating the potential for washback.

- Consistent temperatures ensure throughput reliability and increase product quality.

- Automated cleaning improves and simplifies your processes no matter the stage.

Options & Models

JBT is committed to helping you maximize your plant’s efficiency and uptime. That’s why we offer 24/7 technical support and customize our solutions to fit your business’s specific needs. We don’t just strive to provide you with modern, high-quality machines. Our goal is to help you achieve a personalized production line that gives you a competitive edge in your market and targets your specific goals.

Service & Support

Every NEOCAT Chiller is backed by our PRoCARE® Promise. We offer industry-leading customer service and support. Our 24/7 maintenance support hotline gives you a direct connection to our knowledgeable and experienced service technicians and customer care team who are dedicated to keeping your production lines running smoothly and efficiently. PRoCARE® offers you preventative maintenance, significantly reducing the possibility of having to contend with breakdowns and other costly technical problems.

In addition to on-site maintenance and repairs, you’ll also have access to our many technology centers around the world, as well as hands-on training to make sure you get the most out of your machine.

Parts & Upgrades

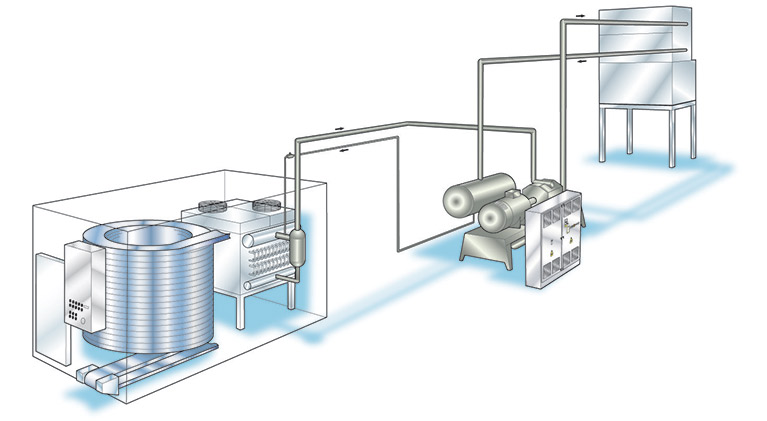

Add JBT’s patented Clean-in-Place (CIP) technology to the NEOCAT chiller to reduce downtime and keep your equipment sterilized and up and running. The automated CIP system cleans with minimal manual labor, cutting costs and improving plant safety and efficiency.

Our innovative design allows you the choice to 1) reduce the equipment’s footprint by 30% compared to previous models OR 2) increase its capacity by 30%. By offering you the choice to modify the size of your NEOCAT to suit your operation, you’re able to optimize your production line and achieve true efficiency that reflects your objectives.

Our dedication to efficiency in terms of operation and cost also allows you to receive individual part replacements and upgrades to stay ahead of the curb and keep your operation running smoothly. We also offer a unique range of lubricants that will help you maintain your system even under the harshest conditions.

We also offer a KillCAT dip tank in a variety of sizes to fit almost any need. Designed for chemical dip solutions for pre and post-chilling applications, the KillCAT comes with adjustable dwell times so you can customize it to fit your plant’s needs.