The demands and rigors faced by producers of poultry, meat, and seafood products are among the most intense across the entire global economic landscape. Tasked with large-scale, constantly evolving consumer preferences; strict safety regulations; and rapid technological change and advancement, you don’t have room to make sacrifices. To succeed in meat, poultry, and/or seafood processing, you must prioritize process efficiency, product quality, and the health and safety of workers and consumers.

Our collection of injectors offers unmatched versatility and can be scaled to meet diverse production-line requirements, delivering superior brine distribution as well as consistent quality and output. Whether you process pork, beef, ham, turkey, chicken, or fish, our injectors empower you with a technological advantage that can bring substantial value to your bottom line while helping you build trust with consumers.

JBT Schröder IMAX Injectors

Superior performance, efficiency, and reliability come together in perfect harmony in our range of IMAX conveyor belts and ECOLINE injectors. Designed and manufactured with German precision, these machines have set the bar high and earned their status as the industry standard. Our success in all applications of bone-in and boneless injection and marination is rooted in our unwavering commitment to quality and consistency.

IMAX injectors are up to any challenge, reliably delivering unparalleled brine distribution and exceptional versatility. They’re robust, highly efficient, and built to supply years of flawless operation. Global leaders in pork, beef, ham, turkey, chicken, and fish processing agree: our injectors bring value to their bottom-line by delivering unmatched technological advantages.

Features & Benefits

Proven production-line methodologies meet cutting-edge technologies when it comes to JBT’s IMAX injection solutions. The injection and marination process demands consistency and precision. Our machinery allows you to harness the power of automated injection technology to achieve optimal performance without sacrificing user control. Here are a few of the key features that distinguish our IMAX Injectors:

- Increased yield – JBT’s conveyor-belt injectors deliver unmatched automated efficiency with injection rates of 3% to 100% and production capacities of up to 40,000 lbs/hour.

- Flexibility and control – Our injectors feature a variety of stitch patterns, needle sizes, and configurations to allow for increased control depending on your needs.

- Hygienic designs – Our conveyor belt and ECOLINE injectors are renowned for their sanitary designs; customer evaluations have demonstrated that IMAX injectors can be cleaned up to six times faster than other machines.

- Durable – IMAX injectors are built to last, expertly crafted to increase lifespan as well as long-term performance quality.

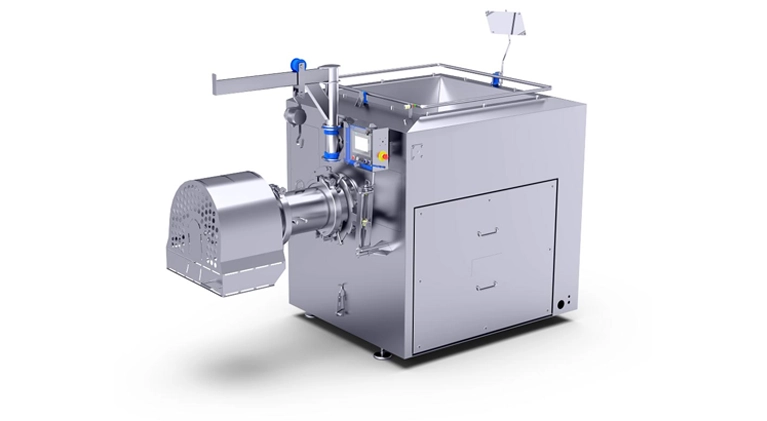

MEPSCO Injectors

Our lineup of MEPSCO injectors, which includes the ULTRACAT, the Junior ULTRACAT, and the ULTRACAT DHI, are designed with efficiency, consistency, and dependability in mind. Built to accommodate all your bone-in and boneless injecting needs, all three models swiftly inject hams, loins, pork bellies, and beef with uniformity and precision. They’re also ideal for marinating whole turkeys, chickens, portioned poultry, fresh steaks, pork, and seafood.

Features & Benefits

With large capacity brine holding tanks, impressive production times, and a variety of needle configurations, the MEPSCO injectors from JBT lead the way in moisture retention, piece-to-piece accuracy, and even distribution. Here are some of the key features and benefits that set these injectors apart:

- Easy to clean – JBT’s MEPSCO injectors are equipped with stainless steel surfaces and a top-of-the line filtration system featuring a self-cleaning drum filter which eliminates 95% of solids. The ULTRACAT DHI also includes the EZ-clean brine head.

- Versatile – These injectors are well-suited to a variety of applications. From hams and pork bellies to portioned poultry and fresh steaks, you’ll be able to enhance a range of products using the same machine.

- Large capacity – The ULTRACAT and the Junior ULTRACAT each boast a 60-gallon brine holding tank, while the DHI features a 112-gallon tank.

Adjustable – With their various needle configurations, fully adjustable injector speeds of up to 55 strokes per minute, and optional 1-way (down) or 2-way full flow (up and down) brine valve, the MEPSCO injectors can easily adapt to a variety of production

JBT: Raising the Bar in FoodTech Solutions

The food-processing industry is fast-paced and competitive. Over the past 100 years, JBT’s relentless commitment to innovation and cutting-edge solutions has never wavered. We’re constantly striving to push the limits of what’s possible in FoodTech. Working with trusted brands and partners around the world, we’ve earned our position as an industry leader, delivering targeted food-processing solutions that increase efficiency, cut costs, and improve your end product.

Your Goals Are Our Top Priority

At JBT, you’re more than just a customer. We aim to build long-term, collaborative partnerships focused on addressing your operational needs now and in the future. Our team of experts takes the time to understand your business and the markets in which you operate, allowing us to deliver targeted solutions that solve your toughest challenges and help you reach your goals today and in the future.

Research & Technology Centers

When you partner with JBT, you get exclusive access to our Research & Technology Centers. These hubs of innovation are truly unique and offer you the opportunity to develop your goals, perfect your processes, and optimize your approach. At our Research & Technology centers, you’ll be able to:

- Examine and test equipment and production-line setups

- Fine-tune your recipes, processes, and techniques

- Work alongside our experts and access specialized products and services, including upgrade kits and parts, service and maintenance, and specialized training

- Validate product safety, quality, and compliance

Industry Expertise at Your Fingertips

Over a century ago, JBT made its debut in the FoodTech industry. Ever since our inception, we’ve been blazing new trails and reaching new heights in a diverse range of food markets. Over the years, we’ve built a name for ourselves as a trusted industry leader. We’re uniquely positioned to provide you with the support and guidance you need to thrive and expand in your market(s). We believe that by working together, we can build a better future in FoodTech.

Contact our team today to learn more about how JBT can help you optimize your operations!