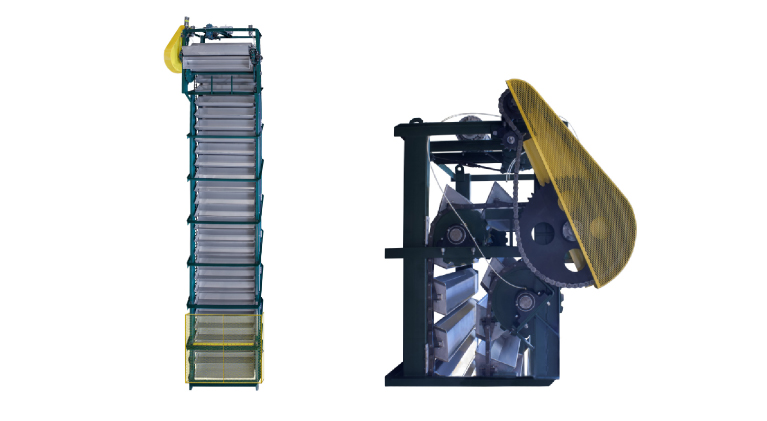

Our Bucket Elevator elevates fruit via a continuous chain with equally pitched buckets. The fruit is then gently off-loaded at a higher elevation onto a conveyor or directly into a fruit holding bin.The bucket elevator can be either a reverse dump or forward dump. The reverse dump is most often preferred for the gentler fruit handling, but both options are available in order to adapt to the configuration of the juice plant.

Features & Benefits

- Continuous and automated process

- Flexible bucket capacity varying between 48″ (1219 mm) to 84″ (2133 mm) widths

- Overloaded buckets are leveled with the aid of a flexible flap over the intake chute

- Solenoid oilers are used to apply oil to the transmission chain and soapy water to the bucket chains

- At full speed, the reverse dump bucket elevator operates from 20 to 36 boxes/minute (818 to 1472 kg/minute), depending on the bucket’s width

Details

- Used for any fruits/vegetables that needs to be moved to a specific location in the plant such as storage bins and unloading areas