Thermal Processing Academy – Aseptic and Canning

Course date: to be defined

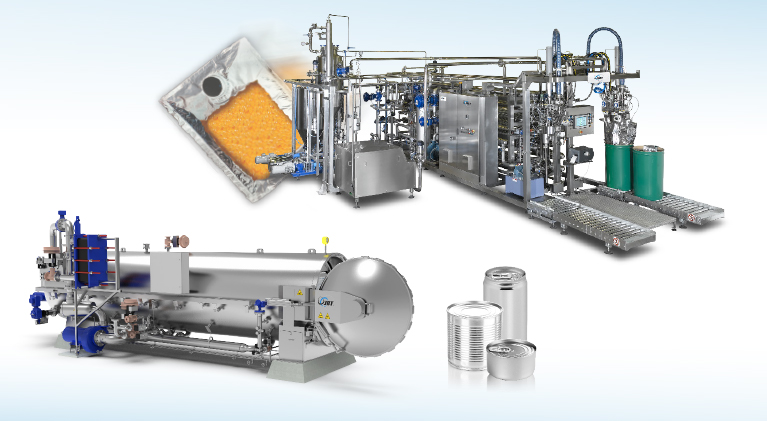

Thermal Processing Academy is structured in such a way that participants will gain knowledge of critical parameters in food safety and the quality of thermally treated products in autoclaves and continuous sterilizers (container processes) as well as “in-flow” (aseptic processes).

COURSE AUDIENCE

Thermal Processing Academy is aimed at all people involved in the production of high quality canned and aseptic food products. Some of the people that fall into this category are: operators and line supervisors, plant engineers, food technologists, new product research and development personnel and quality control personnel.

COURSE CONTENTS

The course will be taught in 5 days to cover all the most important aspects that concern the technological subjects related to the heat treatment of food products, both for canned products and for aseptic products. Once the knowledge is acquired, the participants will be able to understand their responsibility in the quality and safety of processed foods.

Aseptic Processes

Day 1

- Thermal treatment calculation

- Effect of the product viscosity

- Effect of particulate presence

Day 2

- Sterilizers with tubular heat exchanger

- CIP: Cleaning in Place

- SIP: Sterilization in Place

- Aseptic filler

- FDA regulation

In Container Process (Canning)

Day 3

- History of Canning

- Microbiology

- Overview

- Microbiology of Thermal processing

- Sterility/Lethality/General Method (D, Z, Po and Fo values)

- Heat Transfer Concepts

- Retort Systems Overview (Batch, Continuous)

- Concepts of Temperature Distribution

Day 4

- Temperature Distribution

- Heat Transfer Distribution

- Heat Penetration Studies

- Calculation Methods

- General Method

- Ball Formula

- NumeriCAL® software

- Critical factors

Day 5

- Data analysis for Temperature Distribution

- Data analysis for Heat Penetration

- Case study to calculate a process

- Analysis of process deviations

- Practical example with product

CERTIFICATION

At the end of the seminar each participant will receive a training certificate by the “Technical School” of JBT.

CONTACTS

For more information, please contact:

Fabiola Carrillo | [email protected] | +52 222 329 4902 ext. 121

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

More JBT Technical School

- In-container Thermal Processing Skills

- Thermal Processing Academy – Aseptic and Canning

- Better Process Control School

- Aseptic Processing and Packaging Technologies Course

- Advanced Thermal Processing Academy

- Trattamenti termici e non termici per la stabilizzazione microbiologica nell’industria alimentare

- Food Labeling UE-USA

- Preventive Controls for Human Food Training FSPCA

- Food Labeling Compliance Seminar

- JBT Citrus & Technical Related Seminar

- FDA Audit Preparation