Aseptic Process Authority and Validation Services

JBT provides advanced world-wide process authority and validation services in support of aseptic processing and filling technologies. Services include compliance/regulatory audits, aseptic thermal process design, validation of low-acid aseptic filler technologies, and complete FDA-product filing support.

JBT’s team of experienced scientists and laboratories can microbiologically validate a wide array of filler packaging material sterilization technologies. Our proprietary AseptiCAL™ software enables unparalleled optimization of aseptic thermal process design, to include the accurate modeling of aseptic low acid particulate product thermal processes required for the FDA-filing of these products.

Validation Services for:

JBT aseptic systems (low-acid or acid/acidified foods)

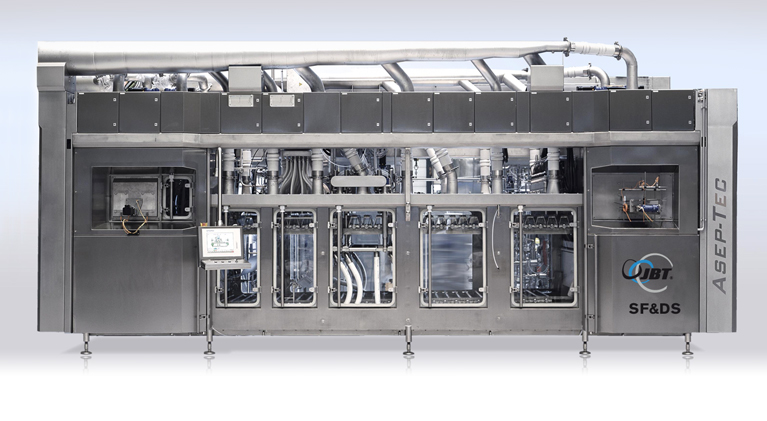

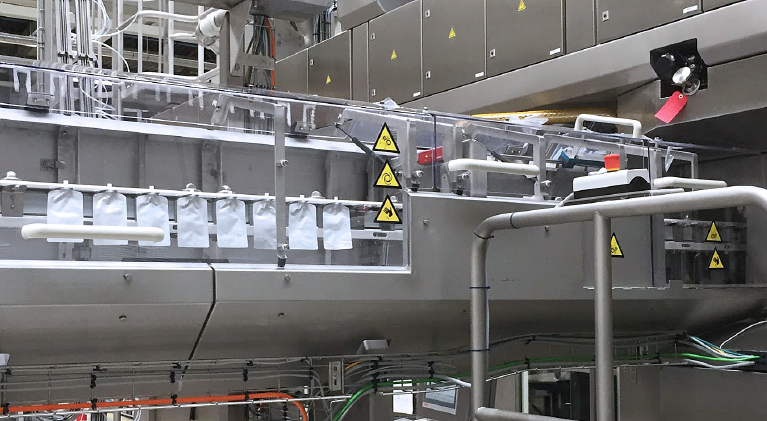

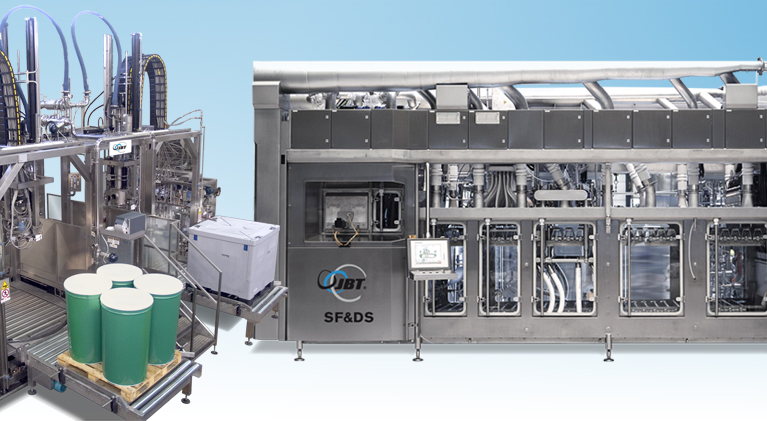

- AsepTec® Linear Fillers

- Bulk fillers

- Sterilizers, aseptic tanks

Non-JBT aseptic and ESL filling equipment (low-acid or acid/acidified foods)

- Bottle, pouch, bulk, paperboard formats

- Peroxide, PAA, peroxide-hybrid, steam-mediated technologies

- Microfiltration “cold sterilization”

- ESL applications (in support of FSMA)

- Sterilizers, aseptic tanks

Validations/Verifications

- Automation/Dynamic Audits

- 21 CFR 11

- Critical factor challenge machine response

- Maintenance of Sterility Testing

- Tetra Pak AQP (Red Book) Audits

Pasteurization technologies

- Nut/low/intermediate moisture foods/high-moisture foods

Other Aseptic/ESL Process Authority Services

- Compliance audits, troubleshooting

- Process design and optimization, product/process assessments

- System compliance review

- Facility audits (21 CFR 108, 113, 117), Quality Systems, Microbiological Program audits

- Process Design Support

- Low Acid UHT Processes (particulate and non-particulate)

- Other processes (acid / acidified foods, ESL)

- Deviation Analysis

- Filing support (deviation analysis and filing support can be offered as yearly service package)

- Troubleshooting

- Cause of Spoilage Investigations

- Training (Thermal process, BPCS, Aseptic)

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support