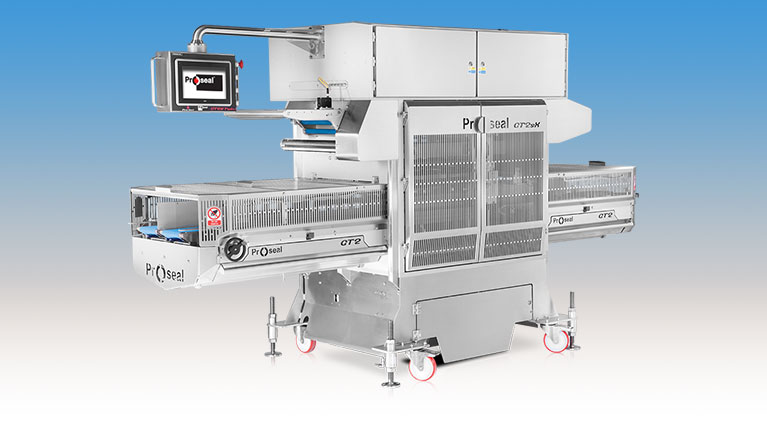

The Proseal GT2sXTwin is an automatic, large-capacity, tray sealing system designed for high-speed production that efficiently cuts labor costs. Available in two formats: extra-wide single lane or twin lane. With increased production capacity the GT2sX has the ability to take packs up to 400mm wide, long edge leading, into the machine. Capable of up to 120 Atmospheric packs per minute with a 6-impression tool the GT2sX system is packed with user-friendly benefits including our unique QR modular conveyor system. The GT2sX-Twin is a high throughput modular, twin-lane, linear, heat-sealing system. It is designed to run in conjunction with auxiliary equipment such as tray de-nesters, fillers, multi-head weighers and labellers, combining into a stand-alone, fully automatic production line. Capable of up to 180 Atmospheric packs per minute with a 10-impression tool, the GT2sX-Twin system is packed with user-friendly benefits including our unique QR modular conveyor system.

Features & Benefits

- Five-minute tool changeover

- Fully portable and castor mounted

- Food industry approved hygienic construction and wash-down protection

- Simple design and operation

- Eseal® energy efficient electric seal system that boasts a massive increase in seal force and a 92% reduction in energy consumption.

- ProMotion high accuracy continuous motion tray infeed system, which increases production speed whilst reducing machine duty.

- QR Conveyors with quick release belts for easy hygiene and maintenance

Details

- Designed to perform the following styles of heat seal to a pre-formed tray; Atmospheric, Gas Flush or Hermetic Shrink, and suited to all relevant food categories including; Fish and Seafood, Pork, Red Meat, Poultry, Soft Fruit, Fresh Produce, Ready Meals and Desserts.

Options & Models

- eWON a machine connection system to deliver real time data and error condition support, remote setup, and software upgrades, using a customer’s existing IT network

- I-film intelligent film reel monitoring system which actively adjusts film tension based on reel diameter to increase print quality and film reel efficiency, reduce component duty, and provides a film end warning system.

- ProTect a contactless machine login and audit trail system

- All around seal only (No Cut) for packs with pre-cut or hinged lids

- Free flow gas flush MAP (Modified Atmosphere Packaging

- High Oxygen (O2) gas flush

- Close Cut – Method of maximizing throughput and reducing film waste

- Inboard Cut (IC) option to provide ‘form, fill and seal’ tray presentation

- Film coding and printing

- Foil crimping

- Active conveyors to allow the machine to be used as a straight through conveyor when packs don’t require sealing

- Pharmaceutical Blister Packaging Machines

- Sandwich Pack Sealing for Board, Recyclable and Non-Recyclable Plastic

- Optional integration of peripheral equipment, such as: de-nesters, fillers, multi-head weighers, laser coders, labelers.

- Hot Rod – long-lasting, water-resistant seal, tool-heating element giving reduced energy consumption especially developed for sealing Smooth Wall Foil Trays

- Sale, Lease Purchase and Rental options available