A Trusted Partner

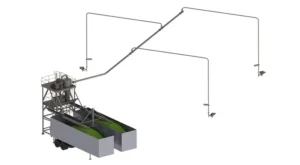

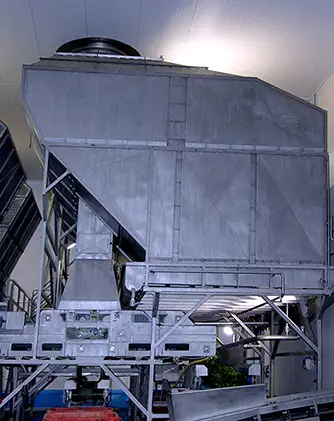

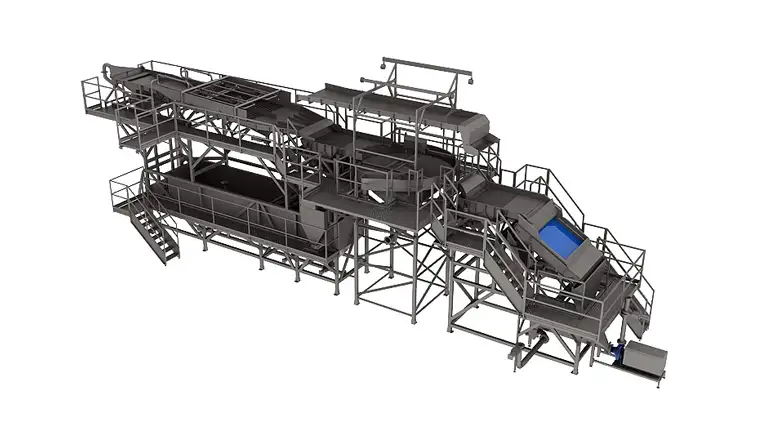

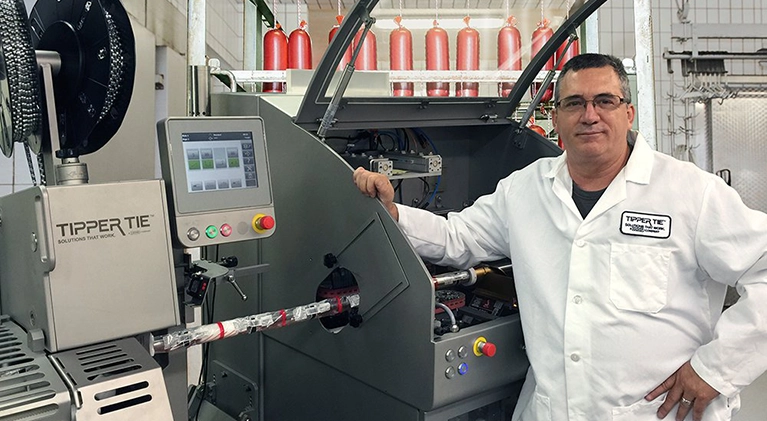

TIPPER TIE provides one-stop, turnkey systems from proposal to installation. Product experts work closely with customers to understand their processes and unique needs. This ensures that equipment recommendations make good business sense for everyone. Consultation with customers identifies cost savings where TIPPER TIE systems influence their operations.

Our commitment to customer support is equally strong. All customers are fully trained in their facilities on the best way to operate and maintain their TIPPER TIE equipment to ensure years of trouble-free service at the highest throughput rates possible. Additional support is provided through “Worry-Free” programs such as our 30-point Wellness Checks and SmartParts program.

JBT TIPPER TIE PRoCARE®

JBT TIPPER TIE PRoCARE® is our branded service level agreement, designed to optimize uptime for your JBT TIPPER TIE equipment by offering a range of fully customizable services that can be adapted to both the size and nature of your organization. Keep in mind that before we even begin our preventative care program, we thoroughly inspect your equipment, establishing a good baseline performance level to ensure everything is running as it should from the start.

Our mission is to provide and ensure productivity. The offering is scalable; we offer you uptime, reduced risk, and a flexible and skilled service partner. Please read more about JBT TIPPER TIE PRoCARE®

Whether delivering turnkey systems, troubleshooting, providing original replacement parts, machine maintenance, or customized training, TIPPER TIE is your trusted partner.

Global Expansion

The depth and breadth of TIPPER TIE’s manufacturing capabilities expand to other parts of the world. Machines and consumables (clips and loops) are produced in the USA, Germany, Brazil, Europe, and China. Worldwide manufacturing has enabled TIPPER TIE to significantly expand its global reach while providing exceptional service to customers in a variety of industries.