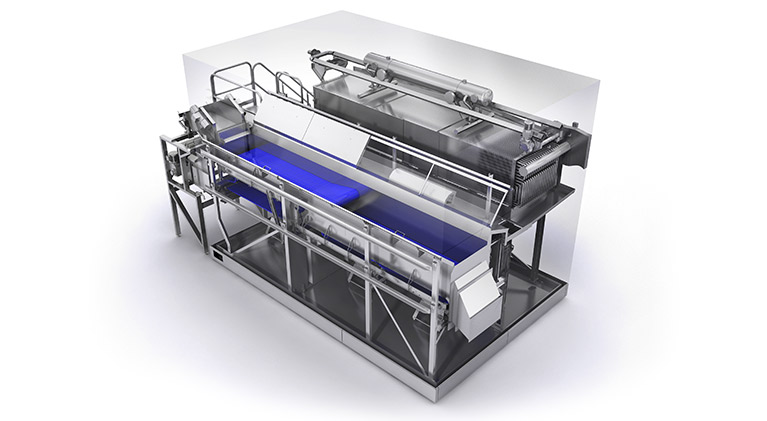

We pioneered “Individual Quick Freezing” technology (IQF), installing the world’s first IQF freezer on a process line in Sweden back in 1962. Since then, millions of tons of fresh food products have been successfully and profitably frozen on our Frigoscandia FLoFREEZE fluidized bed linear freezers. Our Frigoscandia FLoFREEZE provides true fluidization, using a patented air flow system that separates and freezes the most delicate products, while simultaneously fulfilling the industry’s toughest requirements for hygiene, economy and user-friendly operation.

Features & Benefits

- IQF Track – offers stable, dual zone fluidization, with two independent tracks and two separate pressure chambers

- IQF Tray – delivers multi-zone freezing capability using a stainless steel IQF tray which is perfect for products that require extra hygiene precautions and high volume products like peas and corn kernels

- Pulsation system – modulates air pressure and frequency over the product bed that gently separates delicate products at the crust freezing stage

- Agitation – back and forth agitation insures proper IQF at the crust freezing stage and increases throughput

- Air-bypass – fine tune airflow through the product bed to ensure gentle optimized fluidization regardless of product shape, size, and weight.

Details

- Designed specifically for high quality IQF freezing of raw fruits and vegetables

- Capacities from 1 metric ton (2,200 lbs.) to 17,500 metric tons (38,500 lbs.) per hour based on frozen peas

Options & Models

- Options:

- ADF Air Defrost System

- SD Sequential Defrost System

- LVS Refrigeration™ System