Save space, time, effort, and money with JBT’s high-performance, compact digital bench scale

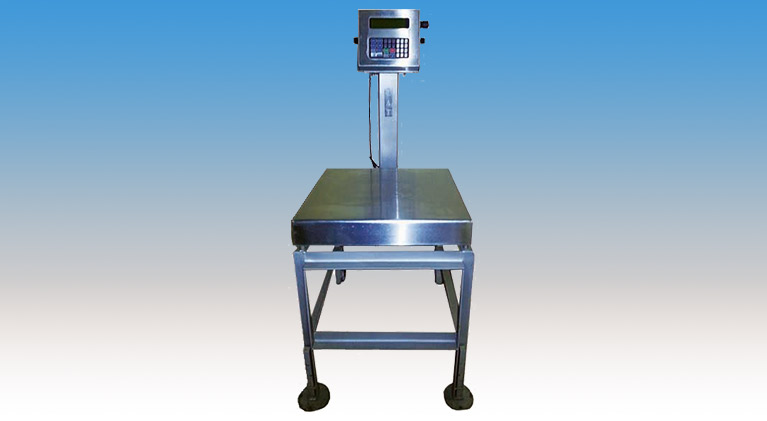

Accuracy and consistency are essential in every aspect of food processing, but nowhere are they more vital than in your weighing and packaging processes. You need to be able to rely on the effectiveness of your scales to ensure product uniformity and quality. The C.A.T. 20” x 20” Bench Scale from JBT delivers unrivaled precision and heavy-duty performance in a compact, portable design to meet your needs.

Built with durable stainless steel and equipped with the standard C.A.T. XTR IP69K Indicators, these scales offer the toughness and ease of use you need to get the job done right and efficiently. With ultra-sturdy adjustable legs, the option to choose from 8” x 8”, 10” x 10”, or 20” x 20” to verify weights, and the ability to weigh products in pounds, ounces, or kilograms, this digital bench-top scale is ideal for a wide variety of processing applications.

Take advantage of cost savings, improved performance, and unmatched versatility to reach new heights in your operations!

Features & Benefits

JBT’s C.A.T. 20” x 20” bench scale sets new standards for weighing technology in food processing systems. With a compact build, superior accuracy, heavy-duty performance, and the ability to audit and verify samples, you can bring your operations into the future while lowering cost of ownership and reducing your overall footprint.

- Built to last – Fitted with a C.A.T. XTR IP69K Indicator, the C.A.T. 20” x 20” Bench Scale can stand up to heavy-duty cleaning, high water pressure, and extreme heat.

- High-quality materials – With heavy-duty steel construction including a flat stainless-steel platter, the system is highly sanitary, resistant to environmental damage, and durable.

- Efficient space-saving design – Don’t let its compact design fool you; this bench scale has a 20” x 20” platform that can handle capacities up to 250 lbs, allowing you to make the most of your space.

- NTEP approved – Our scale complies with important regulatory standards for weighing equipment and has been tested and certified by an approved NTEP testing laboratory.

- Flexible application – This portable bench scale comes with adjustable legs and first-rate casters, allowing you to position the scale to optimize your specific production line(s).

- Accurate weighing and measuring – This scale comes with a bench-top indicator neck and a non-programmable indicator that ensures accurate weight data in lbs, ounces, or kgs depending on your needs and preferences.

Efficient, Versatile, & Cost-effective

When it comes to developing food processing solutions, JBT has always gone above and beyond to meet the ever-growing demands of highly competitive markets around the world. But utilizing cutting-edge, technologically advanced equipment doesn’t have to mean sacrificing your bottom line. True innovation is about giving you the solutions you need to face the toughest challenges in your industry while saving you time and money. That’s why Our C.A.T. 20” x 20” digital bench scale offers you:

- Unmatched accuracy

- Compact and portable design

- Reduced footprint and labor costs

- Easy-to-clean stainless-steel surfaces

- Customizable functionality

- Lower total cost of ownership

- And much more!

FAQs

What is the weight capacity of the C.A.T. 20” x 20” Bench Scale?

Though its small footprint and portable design may suggest minimal efficacy when weighing heavier units, this machine can easily handle up to 250 pounds. Its indicator can also report results in pounds, ounces, and kilograms depending on your needs, allowing you flexibility and saving you the hassle of time-wasting conversions. The scale is constructed with sturdy materials that not only allow it to precisely weigh and verify your products, but also won’t succumb to wear and tear from power washing and other harsh cleaning processes.

Are these scales NTEP approved?

Yes. As an industry-leading FoodTech manufacturer, one of JBT’s primary objectives is to develop processing solutions that comply with government regulations and meet the toughest industry standards. Our expert product developers and engineers designed the C.A.T. 20” x 20” Bench Scale to ensure it conforms to standard requirements in the United States and around the world, and it has been independently tested and certified by the NTEP.

Is the C.A.T. digital bench scale available in other sizes?

Yes! At JBT we understand that one solution rarely fits all. That’s why we prioritize giving our customers a range of options so they can find the perfect piece of equipment to suit their particular production goals and plant needs. Our C.A.T. stainless-steel bench scale is available in sizes 8” x 8”, 10” x 10”, and 20” x 20”.

JBT: Comprehensive FoodTech Solutions for the Future

For over a century, JBT has worked diligently to build our reputation as a customer-focused industry leader in FoodTech. We’re always finding new ways to improve existing food-processing technologies and developing new automated solutions that will help our partners save time and money, increase performance and capacity, and gain a competitive edge in their markets.

Working with JBT, you’ll have the chance to:

- Choose from our extensive catalog of premium equipment

- Customize production designs and approaches

- Integrate equipment from a variety of different brands to optimize your production lines

- Easily access replacement parts and equipment components to keep your operations running smoothly

But we don’t just manufacture cutting-edge, versatile technologies and machinery. We’re also committed to providing the highest level of customer care and support. Take advantage of JBTs personalized services, including upgrade kits, replacement parts, service and maintenance, and specialized training.

Visit Our High-Tech Research Centers

Collaboration is at the heart of everything we do. That’s why we want to ensure that you get access to our behind-the-scenes operation and get a personalized look at our processes. JBT is proud to operate more than a dozen global Research and Technology Centers. With us, you’ll have the opportunity to visit these facilities and work directly with our experts, get a look at our newest technology, test our machines, and try out different production-line set ups.

Take Advantage of Our Industry-Recognized Support Team

If our long history in FoodTech has taught us anything, it’s that meeting your business goals and carving out a unique advantage in competitive markets requires trusted business relationships and individualized support. JBT’s expert support team is globally known for their in-depth knowledge, attention to detail, and personalized approach to customer service.

As a member of the JBT family, you’ll have access to our incredible team 24/7 so that you can get the assistance and insight you need anytime, anywhere. Don’t hesitate to contact us to see how JBT can help you reach your full processing potential.