Revamp your process for transporting semi-solid and liquid products with the C.A.T. Transfer Pump

In industries that handle liquid and semi-solid products, concerns of contamination and lost time have plagued the transfer process for years. With the C.A.T. Transfer Pump, these problems will fade into the past. This automated pump exceeds industry hygiene standards, limits maintenance labor, and saves you valuable time and resources, all while assisting you in developing a clean, quality product every step of the way.

If you work with semi-solid food products, the C.A.T. Transfer Pump has the versatility, functionality, and tailored simplicity to improve your process and keep your operation in top performance. From gizzards, to livers, to filets, to pie fillings, and more, our state-of-the-art machine will get your product where it needs to go smoothly and efficiently.

High-tech Functionality in a User-Focused Design

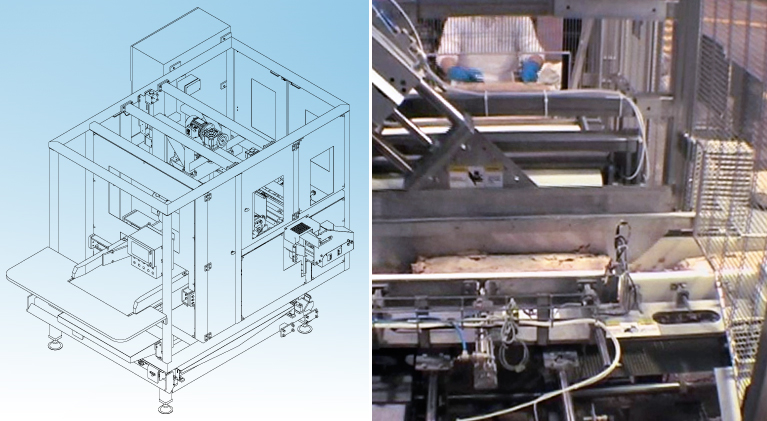

When it comes to efficient transfer pumps, it’s vital to ensure that your equipment has the power, sophistication, and customizability to get the job done right, no matter your goals. The C.A.T. Transfer Pump goes above and beyond to offer you full control over its application while maintaining a simple, intuitive design. It’s superior to costly, ineffective conveyors and provides extensive configuration options. It is universally compatible with other machine brands and is available in 4-, 6-, and 8-inch diameter pumps, ensuring seamless integration with your existing line.

Along with our high-tech equipment and industry knowledge, JBT also offers you the best maintenance support in the business. With 24/7 customer service and our reliable PRoCARE® Promise, we are dedicated to making sure that your equipment provides unmatched efficiency for years to come.

Features & Benefits

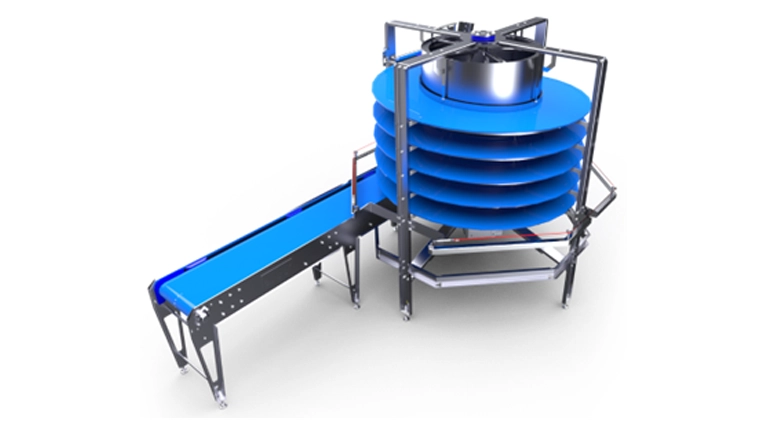

The JBT C.A.T. Transfer Pump is designed to increase your plant’s productivity and output while cutting maintenance and labor costs. Highly customizable to suit your unique needs, the Transfer Pump is available in a variety of configurations and can be paired with our weighing and packing solutions to upgrade your entire production line or be purchased on its own to fit seamlessly into your existing infrastructure.

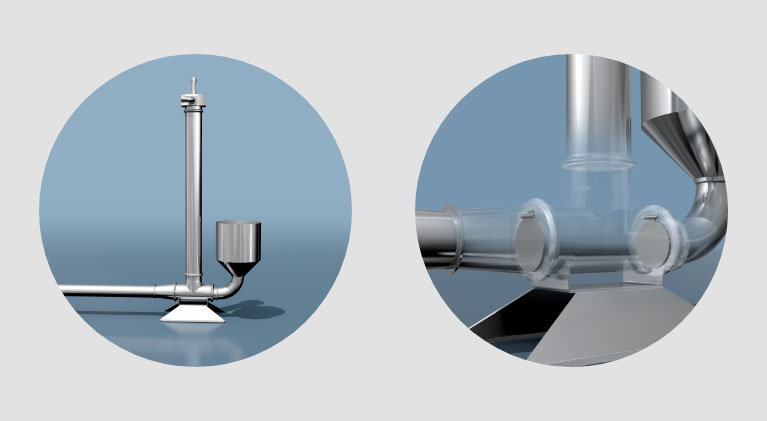

- Hygienic – The pump’s minimalistic design and stainless-steel construction make it one of the most hygienic on the market. Separate pressure and vacuum feeds to the pump eliminate the risk for cross-contamination.

- Universally compatible – Available in 4-, 6-, or 8-inch diameter pump sizes and control panels that are easily fitted to all pump sizes, the Transfer Pump is customizable, versatile, and compatible with all machine brands.

- Low maintenance – With only two moving parts and a stainless-steel construction, parts rarely (if ever) need to be replaced. The pump also uses enclosed pipes to move product, eliminating the need for traditional conveyors, which can be costly and labor-intensive to maintain.

- Easy to clean – Built with clamps, the Transfer Pump is easy to disassemble and clean. Consider adding Clean-in-Place technology for an automated cleaning process.

- Adjustable – The pump’s adjustable analog probe allows you to control the speed and volume of product that’s pumped through the line (flow ranges from 2,000 up to 8,000 pounds / 3,628 kilograms per hour).

- Efficient – The machine pumps liquids and semi-solid products through enclosed pipes using vacuum technology. This eliminates the risk of product loss, which often occurs at transfer points and through evaporation with standard conveyors.

Superior Hygiene & Application Maintenance

When it comes to the production of semi-solid foods, maintaining high sanitation standards is key to manufacturing a high-quality, superior product. This is especially true during the transfer process. Our equipment utilizes fewer machine parts to significantly reduce bacteria and separate pressure and vacuum feeds to virtually eliminate the risk of contamination. You also have the option to add Clean-in-Place technology to further automate and simplify hygiene maintenance.

Cost-Effective

The C.A.T Transfer Pump not only reduces the need for expensive conveyors — it’s also more affordable and far more effective than other transfer pumps on the market. But even beyond its initial price tag, this high-tech machine will continue to save you money every step of the way to increase your bottom line and simplify your entire system.

With its hygienic design and simple approach, the C.A.T. Transfer Pump will maintain its functionality long after other pumps need to be replaced. Our maintenance support is also dedicated to providing you with quality service to keep your operation running smoothly.

JBT – A Trusted Industry Leader

At JBT, our primary goal is to help food producers around the globe confront real-world challenges and rise to the top of their industry. Throughout our over 100-year history, we’ve developed a reputation as a true leader in FoodTech. We’re known for our tenacity and unparalleled technological innovation, but our real secret to success lies in our commitment to maintaining strong relationships with our industry partners.

You know your industry better than anyone, and by utilizing our experience, problem-solving capabilities, and ingenuity there’s nothing we can’t accomplish together. We don’t just use our extensive knowledge to make high-quality machines; we also make it a priority to listen to industry leaders like you, learn about practical challenges, and work tirelessly to set new standards in food processing.

Understanding Diverse Industries

Since our founding, we have continued to raise the bar and expand our reach in FoodTech industries. By prioritizing collaboration and meaningful business relationships, we’ve had the opportunity to work closely with partners in a multitude of domestic and global markets, including:

Gain Access to Our Centers for Research & Development

In this highly competitive and fast-paced industry, innovation is the name of the game. For decades, JBT has pushed the limits of what’s possible in FoodTech, and we’re committed to sharing that progress with you.

When you partner with us, you gain access to our Research and Technology Centers, where you’ll be able to test equipment, collaborate with industry experts, and fine-tune your recipes and processes. Together, we’ll solve your toughest challenges and develop solutions that will help you grow your business and reach your goals now and in the future.

Exceptional Customer Service & Superior Support

At JBT, we do more than just manufacture cutting-edge machinery. We’re committed to providing top-of-the-line service and support to our partners and customizing our solutions to fit your unique needs.

Our PRoCARE® Promise ensures that all of our equipment is backed by industry-leading customer care, and our 24/7 hotline gives you unlimited access to our service technicians who can help you troubleshoot remotely to keep your facility productive and maximize uptime.

Contact us today to join the JBT family!