Line Control and Monitoring

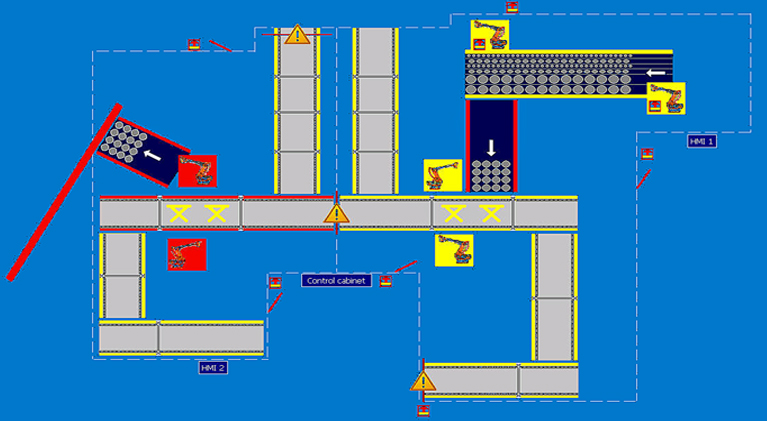

Basket Tracking System

Our Basket Tracking System (BTS) not only coordinates all movements of baskets, but also records all data and monitors preprocess dwell time deviations. The eyes of the BTS are the barcodes that identify the baskets in key locations of the process while they move along: loading (fill time for dwell time tracking), in the retort, process start and process end, and unload.

The BTS flags any anomalies (e.g. baskets with a different product, unsterilized or wrong product at unloader, etc.). In that case, a QC privilege is needed to release any product that has been flagged.

Features & Benefits

- Coordinates all movements of the baskets

- Records all data

- Monitors pre-process dwell time deviations

- Provides a good system overview of the complete Automated Batch Retort System

PRoLINK™ Control System

Deliver maximum throughput, whether in the plant or on the go.Our PRoLINK Controls is the most advanced, universal, web-enabled, recipe-driven touchscreen interface on the market. With PRoLINK Controls, processors are able to control their equipment remotely and access JBT support directly from smart devices. Additionally, PRoLINK Controls boast a sortable database as well as reports and alerts in multiple languages and units of measurement.

Features & Benefits

- Intuitive interface

- Remote accessibility

- Secure connections

- Superior communication capabilities

- Improved uptime

Details

- Analyze live data and respond more quickly and proactively

- Ensure data is protected regardless of location

- Learn and operate simply and consistently across all products and lines

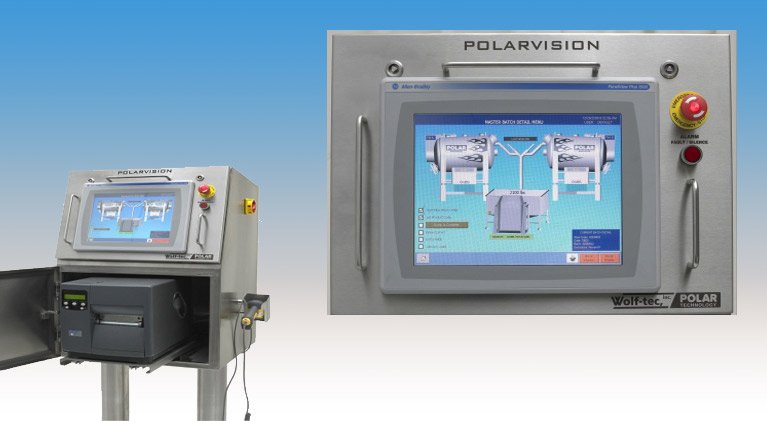

PolarVision™ Process Monitoring

Real time process monitoring and validationNow more than ever, knowing what happens with your product in real time is critical to our industry’s future.PolarVision is a fully integrated and customized closed-looped SCADA system offering real-time process monitoring with pro-active control along with full validation of your entire process or any particular chosen components. Once a process has been defined and is operational, PolarVision controls the process to ensure it remains within specifications. It also allows the processor to remotely monitor and control the process in real-time, while providing operator accountability and alarm/event/ process step notification. PolarVision is an indispensable tool for management that is used for data acquisition, process validation, SPC, trend analysis and data management – all allowing the processor to quickly adapt to process variances.

Options & Models

- Options:

- Radio Frequency Identification (RFID)

- Bar code scanning and bar code printing

- Wolf-tec’s in-house team of experts are developing tailored solutions as a system, as a free-standing shop floor control, or fully integrated within an MES system linking the front office to the shop/production floor

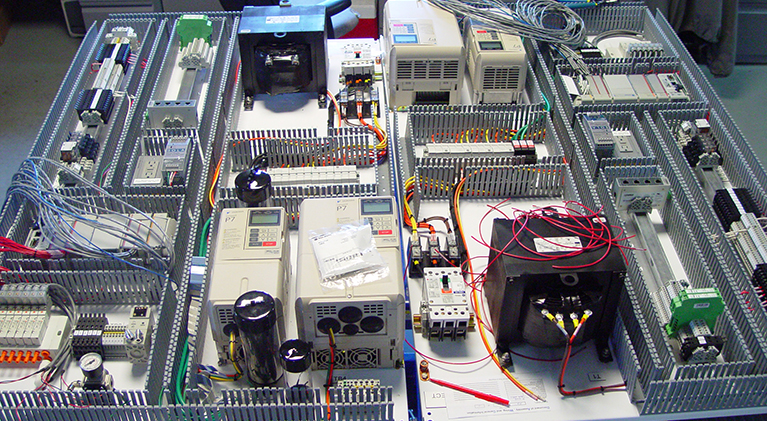

PLC Automation

Instrumentation

We adhere to Current Good Automation Manufacturing Practices (cGAMP) to produce dependable process automation systems that perform to your precise functional requirements. Every automated system is fully tested in the A&B Process Systems Factory Acceptance Center (FAT) before it is shipped to or installed in your facility.

Features & Benefits

- Experience with designing a variety of process control systems which incorporate instrumentation, sensors, intelligent valves, programmable logic controllers (PLC), Human Machine Interfaces (HMI), and Central Supervisory Control and Data Acquisition (SCADA) Systems.

Automation Engineering

We adhere to Current Good Automation Manufacturing Practices (cGAMP) to produce dependable process automation systems that perform to your precise functional requirements. Our process automation capabilities include programming design and development, UL Compliant system assembly, panel assembly, Clean-In-Place (CIP) integration, Human-Machine Interface (HMI) programming, Allen Bradley Systems integration and field start-up services. Every automated system is fully tested in the A&B Process Systems Factory Acceptance Center (FAT) before it is shipped to or installed in your facility.

Features & Benefits

- Electrical Engineering Services

- Electrical Schematic and Panel Layout Drawing Design

- Panel Fabrication

- Skid Wiring

- Programming Services

Details

- Process control/automation design

- Batching and blending recipe management systems

- Heat treatment

- HTST (High Temperature Short Time)

- UHT (Ultra High Temperature)

- Clean-In-Place (CIP) systems

- CIP Circuit Design (Valve sequencing)

- pH, conductivity, Temperature, Pressure and Flow Control

UL Control Panels

We adhere to Current Good Automation Manufacturing Practices (cGAMP) to produce dependable process automation systems that perform to your precise functional requirements. Our UL control panels feature reliable and user friendly controls that are designed for easy maintenance.

Features & Benefits

- Include full package design:

- electrical design

- control panels

- conduit/wiring

- testing

- PLC and HMI programming for stand-alone or fully integrated systems using industry standard programming software:

- Rockwell

- Modicon

- Wonderware

- Intellution

- High quality control panels that are fabricated in our UL508AP398A Panel Shop

- Factory Acceptance Testing (FAT)

- Field start-up and commissioning support