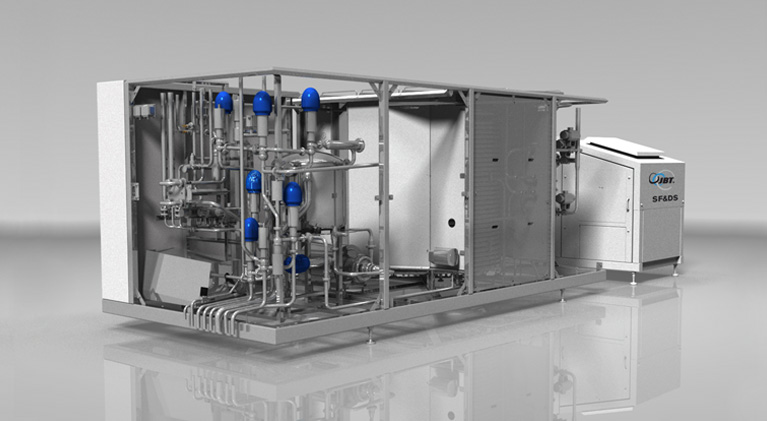

Our SteriCompact is based on JBT’s globally successful UHT system, the Sterideal® HX. Dairy producers worldwide embrace the JBT F&DS UHT concept for its robustness, resulting product quality, ease of operation and favorable TCO. The unique helical configuration of concentric tubes ensures effective thermal treatment combined with efficient heat recovery and optimal product handling. The tubular in-flow processor is used for pasteurizing and sterilizing dairy products, juices and higher viscosity products like tomato sauces and desserts.

Features & Benefits

- Coil design saves energy costs compared to traditional heat exchangers

- Small footprint reduces floorspace requirements

- Proven technology optimizes the taste and shelf-life of end products

- Robust homogenizer design ensures low maintenance costs over entire lifespan

Details

- A compact unit specially designed for the 2000-4000 L/hr (8.8 -17.6 gpm) capacity range

- Maximum process temperature of 144°C (291°F)

Options & Models

- To meet the market demands for small scale productions in emerging markets and specialized products in high end markets, JBT has extended the range of in-flow processors with the SteriCompact. The unit is specifically designed for the lower capacity range of 2000-4000 L/hr. The base SteriCompact for standard dairy applications can be configured with optional modules to process your ESL milk, juices with small fibers or soy products.