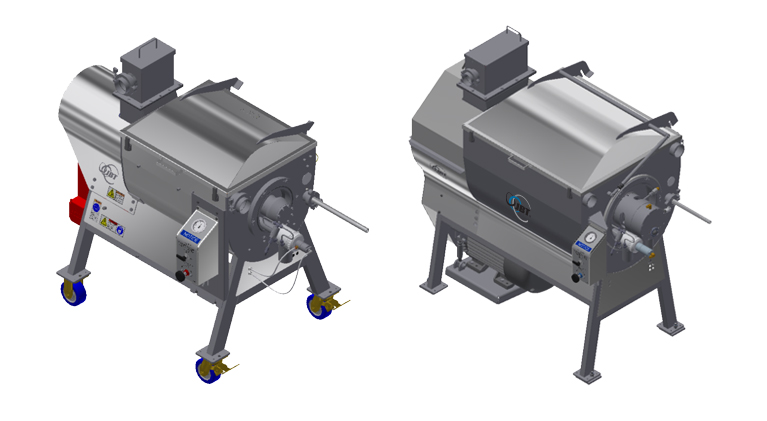

Our extremely flexible UCF110 and UCF210 Screw Finishers work to efficiently separate liquid and solid materials by means of filtration. Incoming product is moved along the finishers via continuous screw. With our models, you maximize all sanitation procedures, while also reducing floor space. UCF110 and UCF210 Screw Finishers are ready for a full range of citrus processing, including juice finishing (separating juice from pulp), oil finishing (separating frit from the oil: water emulsion), recovery of soluble solids (pulp or core wash) core wash and pulp packaging.

Features & Benefits

- Continuous process with minimal intervention from the operator

- Use of centrifugal force with rotating screw makes the process very efficient and simple

- Very flexible; several speed and pressure options dependent on the chosen juice quality specifications

- Maximum sanitation and reduced floor space

- Higher efficiency resulting in the highest yield in the industry

- Automated screen cleaning and easy access to valves and gauges for maintenance

- Reduced down time due to our unique pneumatically-actuated dual spray ring system