The Spine of the Line

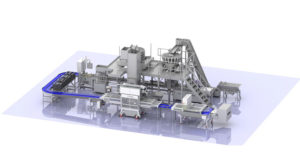

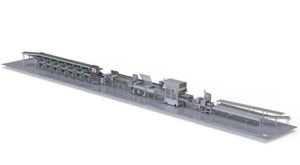

The Proseal tray sealer is an intelligent piece of equipment that during product changeover requires film and tooling to be swapped. For this reason we decided to make the tray sealer the spine of the line of any production line – it makes perfect sense to centralize the entire line set-up through the Proseal Machine’s innovative and intelligent software, avoiding unnecessary delays caused by accessing and setting up the other pieces of peripheral equipment in a large production facility.

This means the operator swapping the product can change the whole line set-up for the next run through the push of a button on their Proseal machine screen; the use of one screen furthermore minimizes the chance of delays as everything is done through one channel, optimizing production speeds and simplifying changeover for the operator.

At Proseal we are able to work with any company that produces production equipment to ensure that electrical, mechanical and systems integration is seamless, whist meeting standards for local safety compliance such as CE Marking.

Proseal GT2 Case Study

High speed production line for multi format ready meals The customer had an increasing need for faster production. Their aim was to produce multi-component meals […]

Get details

Proseal GT5 Case Study

Automatic filling, sealing and Gas Flushing multi component salad bowls With the increased cost of labor in most countries, many food manufactures are looking to […]

Get details

Proseal GT5eX Case Study

The Spine of the Line Ultra high speed fully integrated soft fruit top seal line where product waste is completely minimized and over or underweight […]

Get detailsCONTACT US

We’re here to help every step of the way.