Grow your portioning yield with JBT DSI

When portioning your product, whether it is chicken, beef, pork, seafood, or plant-based, you want to maximize your yields, throughput, and labor efficiency. At JBT, we have vast food processing experience, and our food slicing and portioning solutions are created to meet the challenges you face and help you grow your business.

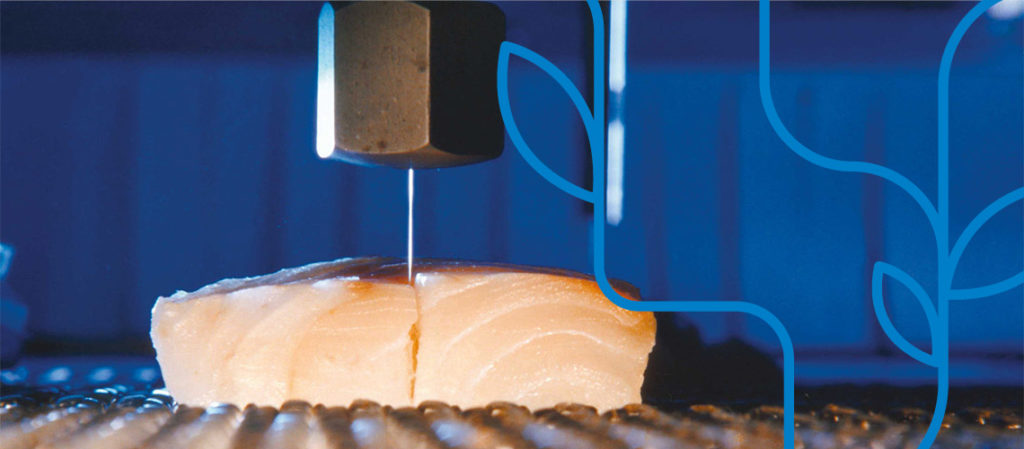

That’s why JBT’s DSI™ waterjet portioners are designed to efficiently and accurately cut, portion, and sort poultry, meat, plant-based, and seafood to produce portioned fillets, nuggets, chunks, strips, and fat-trimmed products. The cutting and portioning of the product is also a process that can significantly reduce food waste and increase yield. Manual cutting is labor-intensive and prone to inefficiency, potential contamination, and higher food waste. The goal is to use every part of the incoming product so nothing goes to waste. Our intelligent DSI waterjet cutting- and portioning system is the automated alternative that, in addition to decreasing labor cost, has proven to improve product yield and increase productivity consistently.

Creating the optimal cutting path

The key is computerized scanning of every piece coming into the machine, and sophisticated programming that controls a high-speed, robotic waterjet cutting head to portion, slice, strip and/or cube. The DSI scans every incoming product and automatically determines the optimum cutting paths to produce the desired outcome. It also evaluates how best to use any remaining product area for additional products like cubes, strips, and nuggets. And with JBT’s automated meat portioning and slicing solutions, you’re also able to respond to shifts in marketplace demands with speed and agility.

JBT’s DSI waterjet portioners can fit into an existing protein processing line or be delivered with other JBT equipment for an all-new high-speed line. Our experts can help you set up a processing line that portions and cuts what you need today and is flexible to adapt to different product needs in the future.

Easy to automate

Lower energy consumption is achieved with a bespoke and exclusive servo pump design that has been ruggedized and sized for the DSI System to meet the needs of food processing facilities. The servo drive system replaces hydraulics and reduces utility requirements, making automation easier to implement as smaller facilities with lower-amp service availability move to automate their portioning processes. Customers new to automated systems with small maintenance teams with minimum experience have proven that the servo pump system is easy to operate and maintain.

The JBT iOPS® System is available with DSI Systems to provide product and machine health data analytics, predictive maintenance, and support of Industry 4.0 advancements. Customers have the option to receive monthly DSI software updates at no charge to benefit from the ever-expanding applications library of DSI Q-LINK™ Portioning Software.

Meet our food processing experts

Anuga FoodTec | Cologne Germany | 26/04/22 – 29/04/22 | Hall 6.1, Stand D030 & F049

Don’t miss the opportunity to discuss your business and challenges with our food processing experts. Together we can target the machines that best accommodate your products, production lines, line speeds, and changing product specifications to improve your product yield, reduce food waste and increase productivity.

Solutions

Time to grow your business with JBT

Fresh produce processing

Fresh produce technologies

High-pressure Processing

Fresh-cut, Robotics, Steaming

Fruit, veg & dairy procession

Filling & preservation

Tray sealing

Protein processing

Portioning Systems

Coating Systems

Frying & Filtering

Grilling, Cooking & Searing

Chilling & Freezing