Setting up a high-performing vegan production line demands experience and knowledge in the art of processing food. In this blog post, we check in on some parameters that influence the cost, function, and sustainability.

Flexibility and capacity in the vegan production line

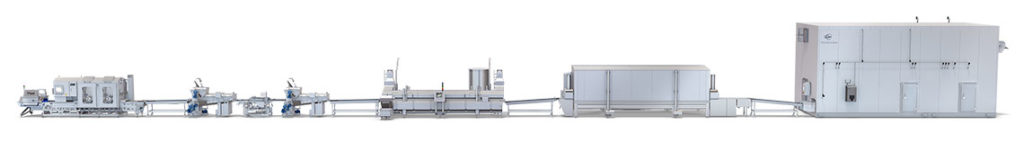

Everyone wants to increase the yield and capacity in their production line, and it’s often more profitable to produce large amounts of a particular commodity than to manufacture multiple products. But, as the vegan segment keeps snowballing, there is also a desire to develop new concepts. Quick turnarounds are one of the reasons why flexibility is crucial when setting up a vegan production line. With versatile equipment, you can manufacture mince today and sausages tomorrow; or expand your meat and poultry assortment without making a substantial investment in new machinery. JBT’s food processing solutions are genuinely flexible and help to grow your business. Once your product is a success, it’s time to scale up the line’s capacity. Our food processing equipment solutions have a capacity that starts at 200 kg per hour and can extend far beyond to meet your requirements. Whenever you need an upgrade or adjustment, we are with you down the line to help you find the optimal solution for your needs.

Minimal footprint

We know that you have limited space in your facility. By choosing compact machinery with multiple functions, you can keep the production line’s footprint to a minimum. We always strive for smartness in our design, and the spiral freezers from our brand Frigoscandia are an excellent example of how form and function perform better together. The spiral freezer uses belts that transport the food vertically instead of horizontally. Apart from being one of the best freezers, it also helps saving space for other necessary equipment in your factory.

Save energy and water

It takes a lot of water and energy to process food. For sustainability and financial reasons, it’s always a good idea to invest in machinery with low consumption. Investigate how innovative technologies can help you create a more sustainable line. For example, an automatic cleaning system recycles and reuses the water without compromising on the quality.

Most vegan production lines involve large freezers that use ammonia as a freezing refrigerant. Being a refrigerant with a very low global warming effect, it can still be dangerous for health reasons in high concentrations. Therefore, the permissible volumes are many times restricted by authorities. When freezing, it’s important to have as low temperature as possible since it increases the overall product quality but also reduces the dehydration of water from the food product. However, pressure drops in the refrigeration piping system make it complicated and expensive to operate at low temperatures.

JBT’s innovative low volume system (LVS) can help decrease these losses by securing that the returns in the refrigeration system consist of only vapor. This reduces the pressure drop, making it efficient to operate at lower and more efficient temperatures while reducing your energy consumption. It also reduces the overall amount of refrigerant by 50%, which significantly affects what overall capacity can be frozen in a plant, given environmental demands. Read more about JBT’s low volume systems here.

Hygienic solutions

To avoid recalls and bacterial outbreaks, you need to secure that your production line always remains sanitary. There are many risk areas when producing food, but JBT has long experience and knows how to mitigate the risks to increase your food safety. For example, you should ensure that your equipment are designed to prevent dirt traps and microbiological growth. Curious about food safety? Read another blog post on the topic.

Connected solutions

Keeping your production running without disruption is key to a successful business. Loss of production means loss of sales and profit. With IoT solutions, you can monitor and detect worn parts or potential issues before they become problems. Connected machinery can also help you see temperature or cooking time deviations that risk leading to food safety problems. All in all, you can improve the total efficiency of your operations and avoid unplanned downtime. Interested in JBT’s connected solutions? Discover JBT iOPS.

Need help growing your business?

Are you still not sure how to design your vegan production line? Whether you are looking for a particular processing machine or a complete solution, choosing a committed full-service partner will help you from idea to service and support. If you wish to know more about our offering, please fill out the form, and we will get back to you shortly.

The Future is Plant-based

Need help developing your product?

With the world’s largest database with application tests and more than 30 years of experience in processing plant-based protein, we know how to make the most out of your product in terms of taste, yield and consistency. The food experts at our Food Technology Centers help you develop your ideas or enhance existing ones. The tests can be conducted on our testing site in person or via live video link or as on-site demonstrations with our mobile lab equipment in your facility.