An efficient freezing process is essential when producing plant-based products. Many factors can affect the performance, like the distance between the freezer evaporator and the compressor suction and the height of the wet return riser. Also, drying the freezer after cleaning can be inefficient and time-consuming, resulting in prolonged downtime. But there is a way to make the freezing process 15% more efficient and, at the same time, reduce the amount of refrigerant by 50%.

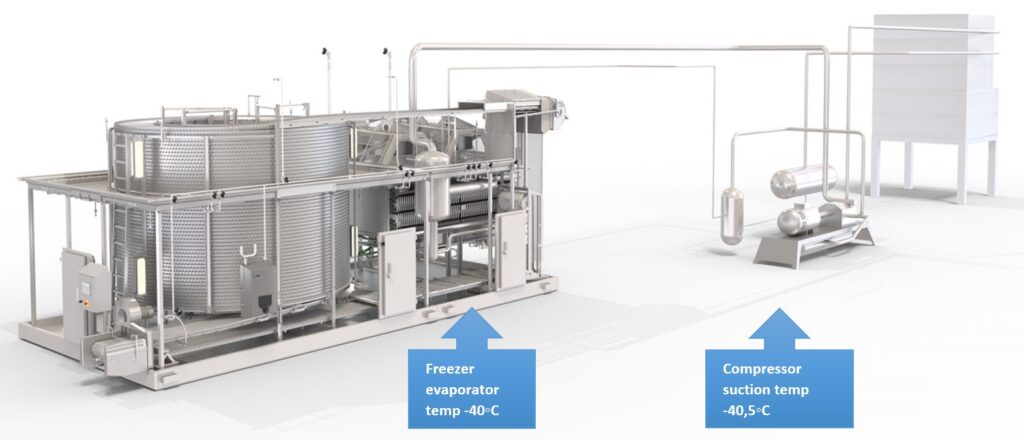

One common challenge when optimizing performance in the freezing process is that the freezer evaporator and the compressor suction often are placed far apart, supported by a pump system. Another challenge is that the wet return riser often is very long due to the high ceiling heights in the plant. When returning the refrigerant to the compressor, these factors can lead to pressure drops, causing temperature or energy losses. By separating liquid and gas close to the freezer – and not far away as in a traditional pumped system – it is possible to gain production capacity or reduce energy consumption.

This insight is the idea behind JBT’s Frigoscandia Low Volume System (LVS) design. The unique invention optimizes the refrigeration system by separating the liquid refrigerant from the gas and regulating the amount, providing a dry return to the compressor, and eliminating the need for wet suction and refrigerant pump. The system becomes less energy demanding and far more efficient with up to 15% higher freezing capacity or 15% lower energy consumption.

Up to 15% more efficient using 50% less refrigerant

In a traditional pumped refrigeration system, pressure drops cause temperature losses of 3-5°C. In a LVS system you only lose 0.5°C, even at very long piping distances. The lower suction loss can improve the freezing performance by either reducing costs or increasing capacity. For instance, if the compressor operates at 1°C warmer at the same capacity, it results in a 3% lower power consumption, reducing energy consumption while maintaining the same throughput with more kilogram product/kWh. Alternatively, with the evaporator temperature of 1°C colder, the freezing capacity increases by 3%.

Every degree Celsius minus is equivalent to a 3% increase in freezer performance, so the 5°C less suction loss with LVS can make a huge difference.

Frigoscandia LVS also makes the freezer more efficient for the customer by reducing the amount of refrigerant by half. The refrigeration technology requires 50% less refrigerant charge than traditional systems because the freezer pipes and evaporators are never fully flooded with refrigerant. The completely dry return to the compressor also minimizes the refrigerant needed. Minimizing the amount of refrigerant is positive because local regulations often have safety demands that increase with the amount of refrigerant charge (in one or more steps). These demands can result in higher costs, e.g., for a full-time refrigeration operator, safety plan, safety equipment, and additional safety training for personnel. In addition, the LVS mainly uses the natural substance ammonia, which has no ozone depletion (ODP) nor global warming (GWP) effects if released into the atmosphere.

Shortening the drying sequence

Another area where Frigoscandia LVS can create a more efficient process is drying the freezer after cleaning. Traditionally drying has been done by running fans. But just as in a household dishwasher, it won’t be completely dry if you don’t open the door to ventilate because it’s hard to get rid of all the moisture with a fan. And in a typical factory environment where conditions are often humid, damp, and warm, using fans to dry is an even slower process. Any attempt made to speed it up risks leaving water in the freezer.

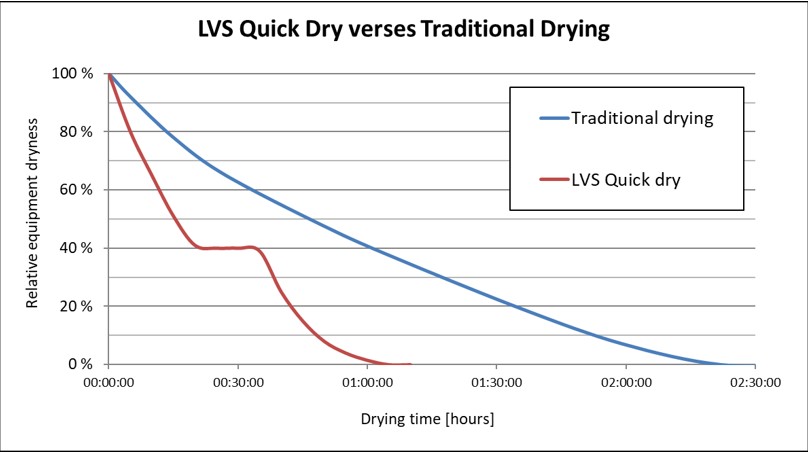

If the freezer is still wet, water can freeze on moving parts, causing problems with the mechanics. Therefore, the freezer must be thoroughly dried out, and this can typically take several hours, especially with mid-sized and large spiral freezers where there’s much steel. Drying often takes up a third of the total cleaning time, so having a dry freezer back in operation as quickly as possible is key to avoiding downtime. However, this is not always the case using conventional drying methods because you end up with a hot freezer that takes a long time to chill down.

A faster and more efficient drying

To address this problem, JBT invented the LVS QuickDry. It’s an innovative solution to drying difficulties that use a patented condensation cycle system to quickly and efficiently remove all droplets of water from Frigoscandia freezers. LVS QuickDry condensates the moisture to the evaporator before quickly heating it with hot gas. This process makes the moisture frozen in the evaporator drip down to the floor, promptly removing most of the water. Unlike most traditional drying systems that can take two-and-a-half hours to achieve results – leading to substantial downtime – the LVS QuickDry shortens the drying sequence by up to one hour and leave the machine cold, saving time and energy.

If you want to know more about how you can make your freezing process more efficient and sustainable with LVS Refrigeration System and LVS QuickDry, don’t hesitate to contact one of our food processing experts. You can book a technical meeting here.

Are you interested in growing your business with JBT?

JBT is here for you! Contact your local sales office or fill out the form, and we will get in touch shortly.