Tissue, Paper & Packaging

Increase Throughput. Cut Waste.

From jumbo rolls to delicate tissue stacks, the paper and tissue industry demands high-throughput and error-free material movement. JBT Automated Systems’ solutions are designed to handle every step of your process—from pulp to pallet—with precision, speed, and care.

Unmatched Quality. Reliable Support.

At JBT, we don’t just build AGVs–we build solutions that power manufacturing and warehouse operations across the globe. Our vehicles are designed, engineered, and assembled in both the USA and Europe. That means every well, sensor, and system is optimized to ensure unmatched quality and tariff-friendly reliability for our customers.

Why Paper & Tissue Manufacturers Choose JBT

Faster Material Flow

Boost production with up to 30% faster throughput, improved on-time delivery, and reduced cycle times.

Reduced Labor Dependency

Cut forklift driver labor by 90%+ and address labor shortages with automated, redundant mobile fleets.

Smarter Cost Savings

Reduce forklift operator costs to the equivalent of $4/hour and save over $6,000 per forklift annually in damage-related expenses.

Intelligent Material Handling

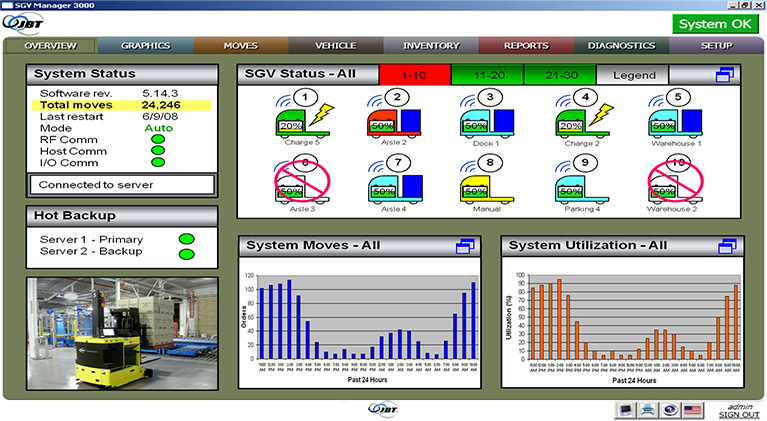

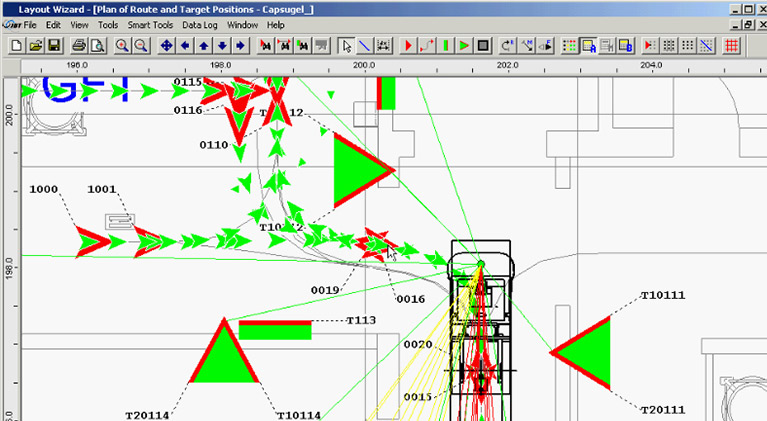

Ensure the right material gets to the right place—faster and more accurately—with mōt.OS, our innovative software that manages multiple fleets and manufacturers in a single operating system.

Zero Errors, Zero Accidents

Achieve a 100% reduction in forklift-related human error and eliminate forklift-related injuries with intelligent safety systems and fully autonomous operation.

Tailored for Paper & Tissue Manufacturing

Our automation solutions are purpose-built to handle a wide range of load sizes and configurations, with the care and control your product quality demands.

Typical Applications:

- Parent roll handling

- Tissue bundle transport

- Reel storage and retrieval

- Roll-to-machine delivery

- Palletizing and stretch-wrapping lines

- Trailer loading and warehouse transfers

Facility Types Served:

- Tissue converting plants

- Paper mills

- Packaging paper producers

- Specialty paper manufacturing

- Rewinder and printing facilities

Vehicle Types:

- Counterbalance forked

- Counterbalance pole

- Counterbalance clamp (roll and box)

- Reach forked

- Automatic trailer loading / unloading

Safety Comes First. By Design

JBT leads the industry in AGV safety with a collaborative risk assessment approach and proactive safety planning that goes beyond compliance.

- Over 500 million safe operating hours in the field

- Active members of ANSI/ITSDF B56.5, ISO 3691-4, A3/RIA R15.08, MAG (MHI), ASTM F45

- Real-time obstacle detection and collision avoidance

- Comprehensive operator and facility training

- Ongoing safety optimization as environments evolve

Your employees’ safety is our top priority—from the first system design to long-term support.

Cybersecurity-Backed Innovation

JBT takes security as seriously as safety. As manufacturers adopt connected technologies, we help protect your operations from evolving cyber threats.

- SOC 2 audited, with ISO 27001 certification pending

- Continuous system updates and hardening

- Secure system architecture to safeguard data and uptime