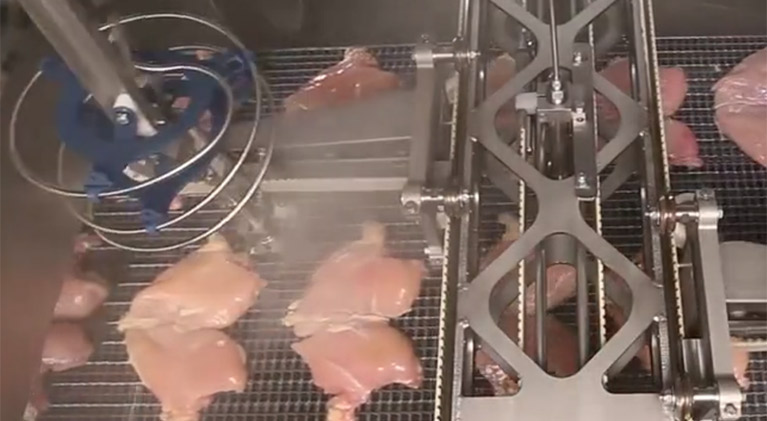

A perfectly flattened schnitzel is characterized by an enlarged surface and standardized, homogeneous product thickness. Our flattening machine guarantees just that! Fresh and frozen products also keep their succulence in the subsequent cooking process thanks to our flattener. Schnitzel, chicken breast filets, boneless tigh meat, gyros, etc. are run over an upper and lower belt through the flattening area, where a number of roller pairs press and stretch the meat in turns. The desired product thickness can be defined in advance by hand through a height adjustment.

The alco flattening machine is designed to flatten and roll out all types of fresh and soft frozen products. The products are conveyed in between the upper and lower belt throughout the whole flattening area. While in the flattening area, the products are alternately pressed and released (patting effect) by three pairs of rollers. The standard built-in hold down conveyor as well as the adjustable outfeed conveyor ensure a gentle transfer of very thin and fresh products to subsequent plants. In the flattening process a standard and homogeneous product thickness is achieved, resulting in constant and reduced cooking times with lower cooking losses as well as an enlarged product surface. The sturdy construction and the precision of the flattening effect alongside simple operation and cleaning represent unique selling points of the alco flattening machine.

Perfectly suitable for roulades, kebab, gyros, schnitzel, chicken breast filets, and boneless thigh meat.

Features & Benefits

- Suitable for all kinds of fresh and soft frozen boneless products

- Continuously adjustable production speed

- Flattening area with a number of roller pairs for gentle and permanent flattening

- Height adjustment through a handwheel for setting the desired product thickness

- Perfect product transfer through a pivotable outlet belt

- Rubberized drive rollers prevent belt slipping

- Water spray bar for preventing protein build up on the belt

Details

- Flattener – Sizes 400mm up to 1000mm (400, 600, 700, 1000mm)

- Flattening thickness adjustable from approx. 4 mm up to 45 mm

- Belt tensioning unit with quick tensioning system and a hinged upper belt frame allow for easier cleaning

- Belt system can be exchanged within minutes without the need for tools

- Collecting trough for product residues under the flattening area for a clean floor