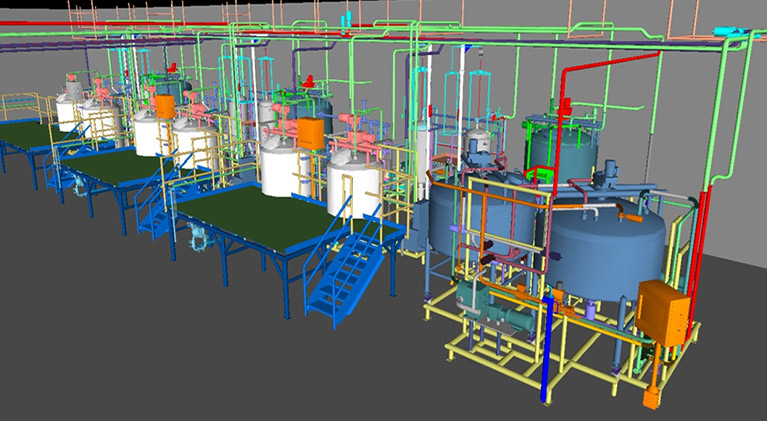

At A&B Process Systems, our preventative care and maintenance specialists work with you and your team to provide a PM program to meet specific needs or a complete plant offering to support you throughout the year. Whether you are looking for weekend downtime assistance to support your staff or a small project to get completed, we have you covered. We have a crew of OSHA trained personnel that are skilled in a multitude of process systems for a variety of markets. Our skilled crews utilize 3A design practices, equipment rigging/setting, demolition, alterations/modifications and relocation of process systems and equipment expertise to meet your critical requirements. Our knowledgeable field staff are trained and certified to repair/modify or replace most process equipment components. Please reach out to our sales team to discuss how A&B can assist you with making your next project a success.

Features & Benefits

- 40+ year experience in Process Systems design, equipment rigging and installation practices

- Multi-disciplined service team to handle small to large projects

- Extensive safety program and Good standing safety record

- Licensed to perform installation services in the US, Caribbean and Mexico

- Highly skilled staff with experience in Food/Beverage, Dairy, Pharmaceutical, Nutraceutical and Cosmetic industries

- Lean manufacturing practices to reduce waste during project life cycle and increase productivity onsite

- Services- Inspections, Remote and/or onsite support, Customized overhauls, Supervision and Operational guidance, training, Preventative Maintenance, Emergency Services,

- ASME certified welders to repair/replace or install on ASME vessels.

- Preventative Maintenance work- Gear box maintenance, valve matrix rebuilds, pump repair, Heat exchanger re-gasketing, pump alignment

- Skid Modifications and Repair

- Instrumentation, piping changes, valves, pumps, disassembly/reassembly- relocations, tie-ins

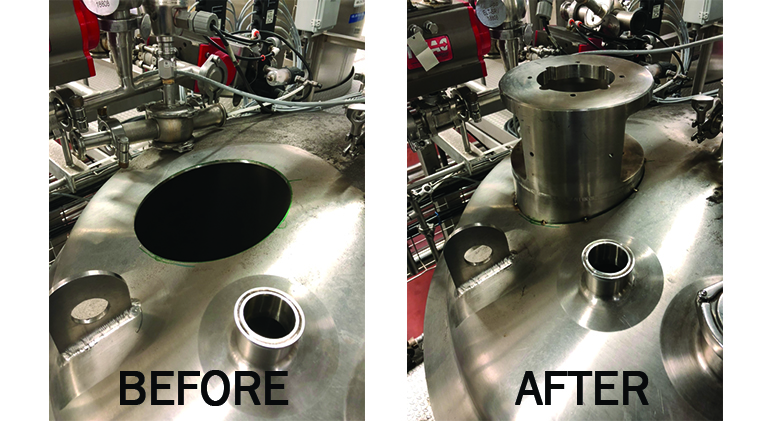

- Tank Service and Inspection

- Dye Penetrant testing, surface repairs, polishing, passivation, leak testing/inspection, EP repair/touchup

- Tank repair capabilities

- Repair/replace/modify- agitators, scraper blades, drive units, bearings, seals, gearbox fluid, fittings/nozzles, agitator bridges, heating/cooling jackets, vessel damage