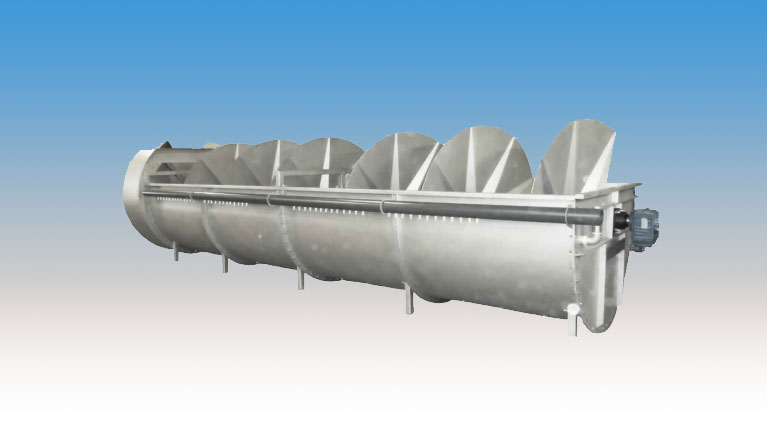

The Tectru GR-TT Gizzard Peeler, distributed by Prime, is designed to increase worker safety by eliminating hand-processing on peeler-roller tables, while delivering a high-yield solution for chicken and turkey gizzards. The high-capacity GR-TT delivers processed gizzards onto a conveyor table for sorting. Gizzards that require rework are slid onto an sub-conveyor that leads to a repeeling bank. Re-worked gizzards are then delivered back to the inspection conveyor for a second visual check and additional rework if needed.

Features & Benefits

- Increases worker safety – no exposure to peeler rollers

- High volume design for maximum throughput

- Up to 12,5000 gizzards per hour, depending on re-work needs

- Saves labor over hand grading/processing

- High-yield repeeler minimizes product loss

- Efficient cleaning of gizzards through mechanical peeler-rollers

Details

- Electrical requirements: 480V, 60Hz; 20A

- Water requirements: 7 GPM

- Weight: 850 pounds

- Production Rate: Up to 12,500 gizzards per hour, depending on size